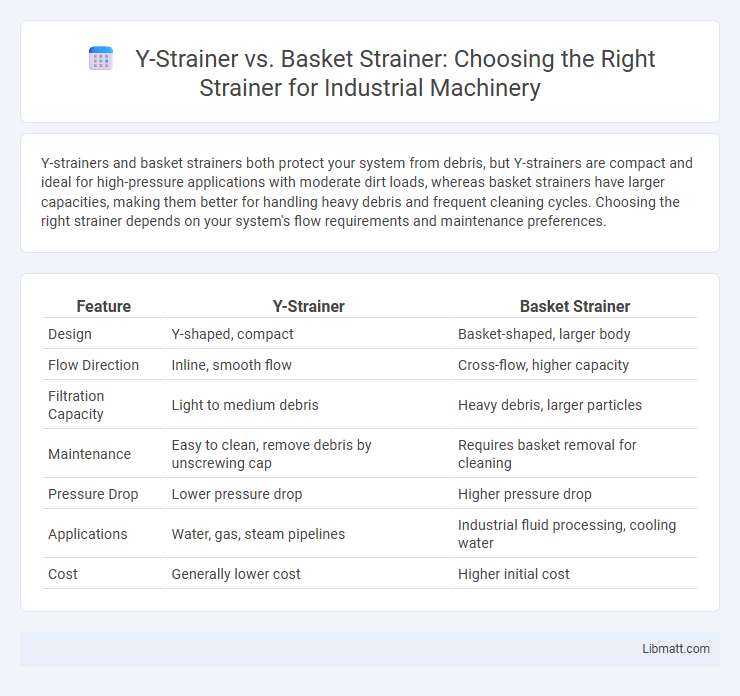

Y-strainers and basket strainers both protect your system from debris, but Y-strainers are compact and ideal for high-pressure applications with moderate dirt loads, whereas basket strainers have larger capacities, making them better for handling heavy debris and frequent cleaning cycles. Choosing the right strainer depends on your system's flow requirements and maintenance preferences.

Table of Comparison

| Feature | Y-Strainer | Basket Strainer |

|---|---|---|

| Design | Y-shaped, compact | Basket-shaped, larger body |

| Flow Direction | Inline, smooth flow | Cross-flow, higher capacity |

| Filtration Capacity | Light to medium debris | Heavy debris, larger particles |

| Maintenance | Easy to clean, remove debris by unscrewing cap | Requires basket removal for cleaning |

| Pressure Drop | Lower pressure drop | Higher pressure drop |

| Applications | Water, gas, steam pipelines | Industrial fluid processing, cooling water |

| Cost | Generally lower cost | Higher initial cost |

Introduction to Y-Strainers and Basket Strainers

Y-strainers and basket strainers are essential filtration devices used in pipelines to remove debris and protect equipment from damage. Y-strainers feature a compact, angled design suitable for high-pressure systems and minimal space, while basket strainers have a larger, cylindrical body ideal for handling higher volumes of contaminants. Both types improve system efficiency by preventing clogging and ensuring smooth fluid flow in industrial applications.

What is a Y-Strainer?

A Y-strainer is a mechanical device used in pipelines to filter out debris and protect equipment such as pumps, valves, and meters from damage and clogging. It features a Y-shaped body that houses a mesh screen or perforated metal element, allowing fluid to flow while capturing particulate matter. Your system benefits from Y-strainers by ensuring smoother flow and reduced maintenance needs compared to basket strainers, which have a larger filtration area but a bulkier design.

What is a Basket Strainer?

A basket strainer is a filtration device used in pipelines to remove debris and protect pumps, valves, and other equipment by trapping particles within a large, cylindrical or square mesh basket. Its design allows for higher dirt-holding capacity and easier maintenance compared to Y-strainers, making it ideal for applications with heavy solids or slurries. Basket strainers are commonly used in water treatment, chemical processing, and industrial systems requiring frequent cleaning and efficient particle separation.

Key Differences Between Y-Strainers and Basket Strainers

Y-strainers feature a compact, angled design that efficiently removes debris from pipelines with minimal pressure drop, making them ideal for high-pressure applications. Basket strainers have a larger straight-through flow path, allowing for higher dirt-holding capacity and easier cleaning, suitable for systems with heavier particulate loads. Your choice depends on flow direction, maintenance frequency, and the nature of contaminants in your fluid system.

Design Features and Construction

Y-strainers feature a compact, angled design with a mesh filter element positioned at a 45-degree angle, allowing efficient debris removal while maintaining a streamlined flow path. Basket strainers have a larger, cylindrical construction with a removable perforated basket to capture and hold particles, ideal for applications requiring frequent cleaning and higher debris capacity. Your choice depends on space constraints and maintenance frequency, as Y-strainers offer a more compact installation, whereas basket strainers provide easier access for thorough cleaning.

Filtration Efficiency and Particle Retention

Y-strainers offer high filtration efficiency by effectively removing smaller particles from fluid systems, typically capturing debris down to 40 microns. Basket strainers excel in particle retention by holding larger volumes of contaminants due to their spacious design, making them ideal for systems with heavy particulate loads. Choosing the right strainer depends on your need for either finer filtration or greater debris capacity to ensure optimal system protection.

Installation Requirements and Space Considerations

Y-strainers require less installation space due to their compact and angled design, making them ideal for tight piping systems. Basket strainers, with their larger, cylindrical shape, demand more room for installation and easier access for cleaning or element replacement. Your choice depends on available space and maintenance access needs in your piping configuration.

Maintenance and Cleaning Procedures

Y-strainers feature a compact design that allows for straightforward removal and cleaning of the strainer element without dismantling the entire pipeline, making maintenance quicker and less labor-intensive. Basket strainers have a larger capacity for debris collection, requiring periodic removal of the basket for thorough cleaning, which can be more time-consuming due to their size and the need to isolate the strainer from the system. Regular inspection intervals and proper isolation valve operation are critical for both types to prevent downtime and ensure optimal filtration efficiency.

Typical Applications for Each Strainer Type

Y-strainers are commonly used in pipelines requiring the removal of debris from liquids, gases, or steam, especially in chemical processing, water treatment, and HVAC systems where space constraints exist. Basket strainers are ideal for systems with higher flow rates and larger debris, frequently found in industrial processes, oil refineries, and pumps, as they offer a larger straining surface and easier maintenance access. Both strainer types protect valuable equipment by preventing contamination and ensuring smooth operation in their respective applications.

Choosing the Right Strainer: Y-Strainer vs Basket Strainer

Y-strainers and basket strainers differ primarily in their design and application, with Y-strainers offering a compact, angled design ideal for high-pressure systems and fine particle filtration. Basket strainers feature a larger straining area and are suited for systems with higher flow rates and larger debris, making them easier to clean and maintain. Selecting the right strainer depends on factors like flow capacity, particle size, maintenance frequency, and system pressure requirements.

Y-strainer vs basket strainer Infographic

libmatt.com

libmatt.com