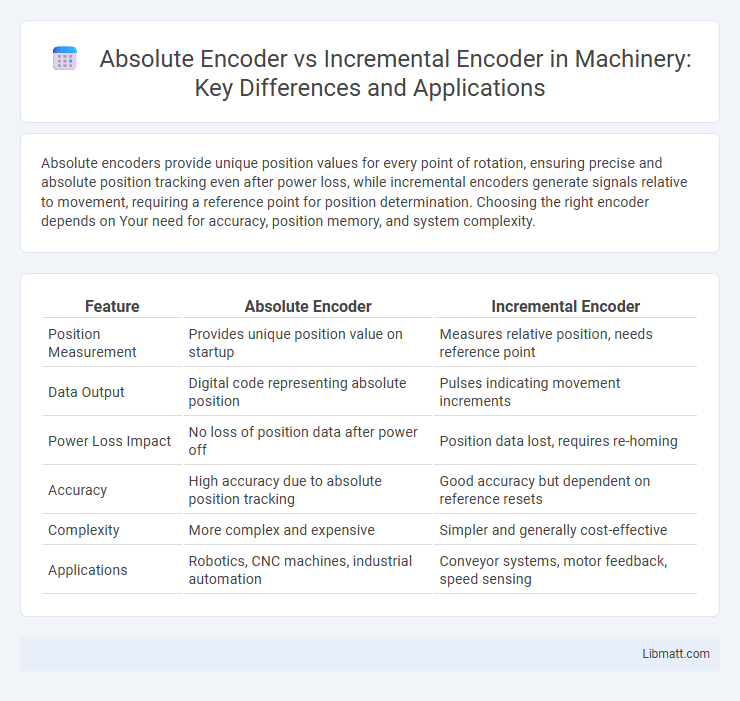

Absolute encoders provide unique position values for every point of rotation, ensuring precise and absolute position tracking even after power loss, while incremental encoders generate signals relative to movement, requiring a reference point for position determination. Choosing the right encoder depends on Your need for accuracy, position memory, and system complexity.

Table of Comparison

| Feature | Absolute Encoder | Incremental Encoder |

|---|---|---|

| Position Measurement | Provides unique position value on startup | Measures relative position, needs reference point |

| Data Output | Digital code representing absolute position | Pulses indicating movement increments |

| Power Loss Impact | No loss of position data after power off | Position data lost, requires re-homing |

| Accuracy | High accuracy due to absolute position tracking | Good accuracy but dependent on reference resets |

| Complexity | More complex and expensive | Simpler and generally cost-effective |

| Applications | Robotics, CNC machines, industrial automation | Conveyor systems, motor feedback, speed sensing |

Introduction to Rotary Encoders

Rotary encoders convert angular position or motion into digital signals for precise measurement and control in automation and robotics. Absolute encoders provide unique position values for each angle, enabling immediate position recognition without reference points, while incremental encoders generate pulses relative to movement and require external tracking for position determination. The choice between absolute and incremental encoders depends on application needs such as accuracy, speed, and system complexity.

What is an Absolute Encoder?

An absolute encoder provides a unique position value for each shaft angle, enabling precise and continuous position tracking without losing data during power interruptions. Unlike incremental encoders, it generates a distinct digital code for every angular position, ensuring accurate and reliable feedback in motion control systems. Your automation setup benefits from absolute encoders by maintaining exact position information at startup, enhancing system safety and efficiency.

What is an Incremental Encoder?

An incremental encoder is a rotary or linear sensor that generates output signals corresponding to motion increments, providing relative position and speed information based on pulses emitted during movement. It does not retain position data when power is lost, requiring a reference point or homing sequence to establish absolute position upon startup. Commonly used in industrial automation and robotics, incremental encoders offer high-resolution feedback but must be paired with control systems for precise position tracking.

Key Differences Between Absolute and Incremental Encoders

Absolute encoders provide a unique position value for every shaft angle, ensuring accurate position tracking even after power loss, while incremental encoders generate pulses corresponding to movement and require a reference point for position determination. Absolute encoders use multi-turn or single-turn technology to deliver consistent position data, whereas incremental encoders rely on counting pulses from a known reference to measure relative motion. Your choice between absolute and incremental encoders depends on the need for precise position retention and the complexity of your application.

Accuracy and Resolution Comparison

Absolute encoders provide higher accuracy and resolution by delivering unique position values for each shaft angle, ensuring precise and reliable position tracking even after power loss. Incremental encoders offer relative position feedback with resolution dependent on pulse count per revolution, which can lead to cumulative error without a reference mark. Accuracy in absolute encoders typically ranges from 12 to 23 bits of resolution, while incremental encoders often achieve lower resolution, making absolute encoders preferable for applications requiring exact position feedback.

Data Output and Signal Types

Absolute encoders provide unique position values for each shaft angle, outputting a digital code or serial communication signal that represents the exact position, ensuring no positional loss during power interruptions. Incremental encoders generate pulses corresponding to movement increments, typically outputting quadrature signals or pulse trains that require a reference position to determine absolute location. The data output of absolute encoders is inherently position-specific, while incremental encoders rely on counting pulse changes and directional signals for relative position tracking.

Power Failure and Position Recovery

Absolute encoders provide immediate position data upon power-up, ensuring zero loss of position information during power failures, which is crucial for precision applications. Incremental encoders require a reference return to a known position after power restoration, causing delays and potential errors in position recovery. Choosing an absolute encoder safeguards your system against downtime and inaccuracies related to power interruptions.

Common Applications of Absolute Encoders

Absolute encoders are widely used in robotic arms, CNC machines, and industrial automation where precise position tracking is critical for repeatability and accuracy. These encoders provide unique position values at each point along the rotation, making them ideal for applications requiring reliable feedback after power loss or interruptions. Your choice of an absolute encoder ensures continuous position awareness, crucial in medical imaging devices and aerospace systems.

Typical Uses for Incremental Encoders

Incremental encoders are commonly used in applications requiring real-time position tracking and speed measurement, such as CNC machines, robotics, and conveyor systems. Their ability to provide high-resolution feedback on position changes makes them ideal for motion control and automation tasks. Industries like manufacturing and automotive rely on incremental encoders to monitor rotational speed, direction, and displacement with precision.

Choosing the Right Encoder for Your Application

Choosing the right encoder depends on your specific application requirements, such as position accuracy, speed measurement, and system complexity. Absolute encoders provide unique position values for each shaft rotation, ideal for applications requiring precise position tracking and power-off data retention. Incremental encoders measure relative movement with pulses, offering simplicity and cost-effectiveness for speed control and less complex positioning tasks.

Absolute encoder vs incremental encoder Infographic

libmatt.com

libmatt.com