PLC offers greater flexibility and scalability compared to relay logic, enabling complex control processes to be programmed and modified with ease. Your automation system benefits from faster operation, enhanced reliability, and simplified troubleshooting when using PLC over traditional relay logic.

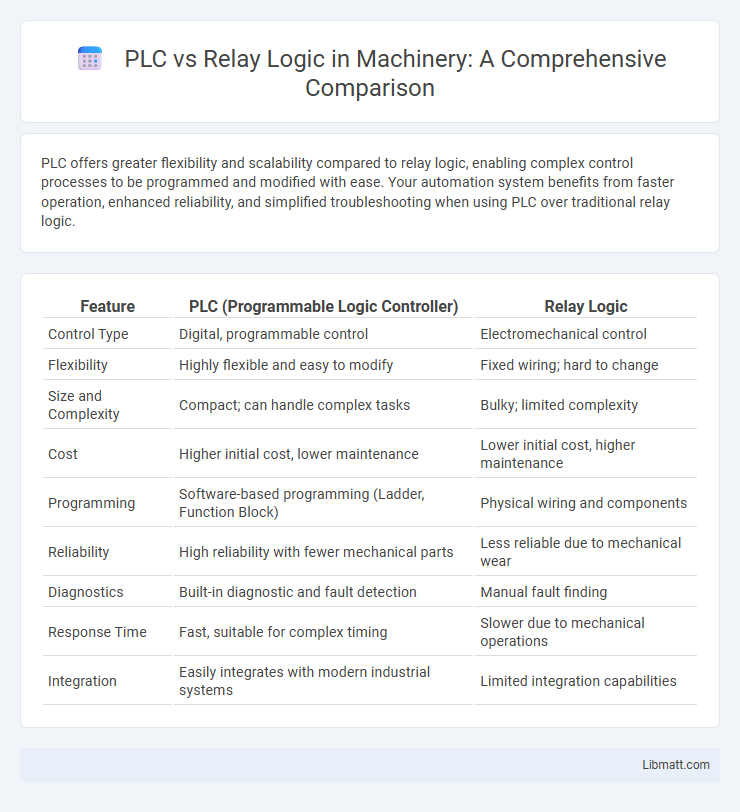

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | Relay Logic |

|---|---|---|

| Control Type | Digital, programmable control | Electromechanical control |

| Flexibility | Highly flexible and easy to modify | Fixed wiring; hard to change |

| Size and Complexity | Compact; can handle complex tasks | Bulky; limited complexity |

| Cost | Higher initial cost, lower maintenance | Lower initial cost, higher maintenance |

| Programming | Software-based programming (Ladder, Function Block) | Physical wiring and components |

| Reliability | High reliability with fewer mechanical parts | Less reliable due to mechanical wear |

| Diagnostics | Built-in diagnostic and fault detection | Manual fault finding |

| Response Time | Fast, suitable for complex timing | Slower due to mechanical operations |

| Integration | Easily integrates with modern industrial systems | Limited integration capabilities |

Introduction to PLC and Relay Logic

Programmable Logic Controllers (PLCs) are digital computers used for automation of electromechanical processes in industries, offering flexible, programmable control with high reliability and ease of troubleshooting. Relay logic relies on physical relays and hardwired connections to perform control functions, typically involving more complex wiring and less adaptability to changes. PLC systems enable faster modifications and integration with modern software, making them preferred over traditional relay logic in most industrial automation applications.

Evolution of Industrial Control Systems

Industrial control systems evolved from basic relay logic, relying on electromechanical relays for control and automation, to programmable logic controllers (PLCs), which offer digital precision and adaptability in complex processes. PLCs enable you to reprogram control sequences swiftly without hardware changes, enhancing efficiency and reducing downtime compared to traditional relay systems. This shift reflects the industry's move toward integrated, flexible automation essential for modern manufacturing and process control environments.

How Relay Logic Works

Relay logic operates through electromechanical switches called relays that open and close circuits to control electrical devices. Each relay coil, when energized, actuates contacts that either complete or break the circuit path, enabling control of outputs such as motors or lights. This method relies on physical wiring and sequential relay arrangements, creating a hardwired control system that executes logic functions through these interconnected relays.

How PLCs Operate

PLCs operate by continuously scanning inputs, executing a programmed logic sequence, and updating outputs in real-time to control machinery or processes. They use a central processing unit (CPU) to interpret ladder logic or other programming languages, allowing flexible and complex control compared to fixed relay logic systems. Your automation system benefits from PLCs' ability to quickly adapt to changes, diagnose faults, and communicate with other devices through networks.

Key Differences Between PLCs and Relay Logic

PLCs (Programmable Logic Controllers) offer programmable control with high flexibility and complex logic processing, whereas relay logic relies on fixed wiring and mechanical relays for simple on/off control. PLCs enable easy modification through software, reducing downtime and maintenance costs, while relay logic requires physical rewiring for changes, leading to increased labor and error risks. Additionally, PLCs support integration with advanced sensors and communication networks, providing enhanced diagnostics and scalability compared to relay-based systems.

Advantages of Using PLCs

PLCs offer superior flexibility and scalability compared to relay logic, enabling easy reprogramming and integration with modern automation systems. They provide faster response times and enhanced diagnostic capabilities, reducing downtime and maintenance costs. Your industrial processes benefit from improved precision and reliability with PLCs, supporting complex control tasks that relay logic cannot efficiently handle.

Advantages of Using Relay Logic

Relay logic offers simplicity and durability, making it ideal for straightforward control tasks and harsh environments where electronic components may fail. Its easy troubleshooting and maintenance reduce downtime, especially in systems with limited complexity. You benefit from cost-effective implementation when advanced programmability and flexibility are not essential.

Typical Applications for PLCs and Relay Logic

PLCs excel in complex automation tasks such as manufacturing assembly lines, process control, and robotic systems where programmability and flexibility are crucial. Relay logic remains suitable for simple, repetitive operations like basic motor starters, lighting controls, and small-scale machinery due to its straightforward design and reliability. Your choice between PLCs and relay logic depends on the required scalability, complexity, and ease of troubleshooting for the specific industrial application.

Cost Comparison: PLCs vs Relay Logic

PLCs generally have higher initial costs compared to relay logic due to advanced microprocessor components and programming capabilities, but offer lower long-term expenses through reduced wiring and maintenance. Relay logic systems incur lower upfront investment but lead to increased labor and troubleshooting costs as complexity grows. Your choice should weigh initial budget constraints against total cost of ownership for scalable and efficient automation.

Choosing the Right Control System for Your Needs

Selecting the right control system depends on factors such as complexity, scalability, and cost. Programmable Logic Controllers (PLCs) offer flexible programming, easy modifications, and integration with modern automation systems, making them suitable for complex or evolving processes. In contrast, relay logic provides simplicity and durability for straightforward, fixed control tasks but lacks adaptability and advanced communication capabilities.

PLC vs relay logic Infographic

libmatt.com

libmatt.com