A clutch is a mechanical device that engages and disengages power transmission between the engine and the drivetrain, allowing smooth gear shifts in vehicles, while a coupling connects two shafts to transmit torque without allowing relative motion. Understanding the difference helps you maintain and troubleshoot automotive or industrial machinery more effectively.

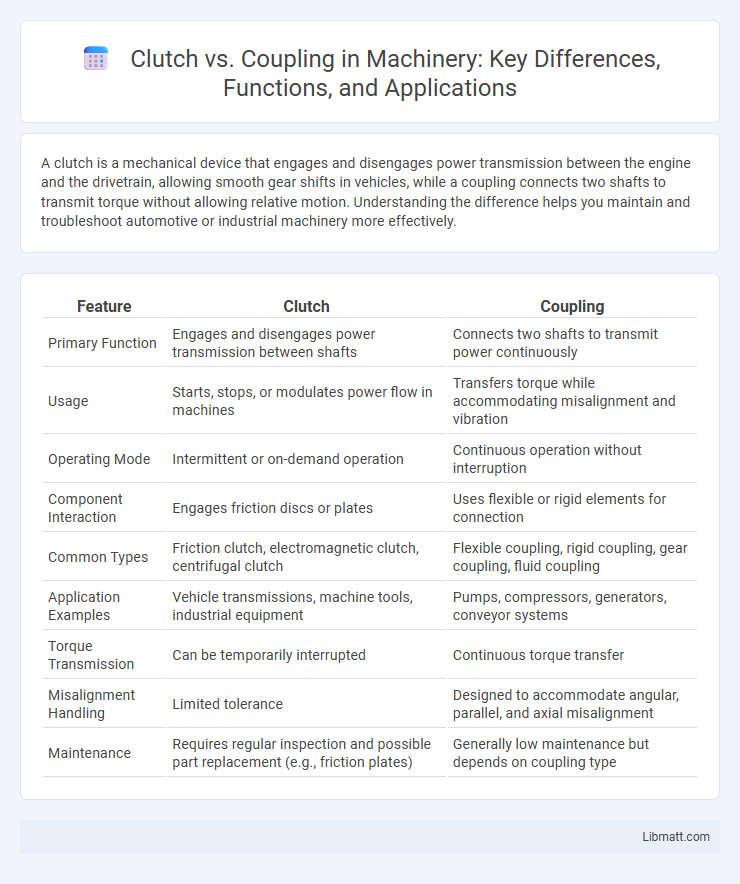

Table of Comparison

| Feature | Clutch | Coupling |

|---|---|---|

| Primary Function | Engages and disengages power transmission between shafts | Connects two shafts to transmit power continuously |

| Usage | Starts, stops, or modulates power flow in machines | Transfers torque while accommodating misalignment and vibration |

| Operating Mode | Intermittent or on-demand operation | Continuous operation without interruption |

| Component Interaction | Engages friction discs or plates | Uses flexible or rigid elements for connection |

| Common Types | Friction clutch, electromagnetic clutch, centrifugal clutch | Flexible coupling, rigid coupling, gear coupling, fluid coupling |

| Application Examples | Vehicle transmissions, machine tools, industrial equipment | Pumps, compressors, generators, conveyor systems |

| Torque Transmission | Can be temporarily interrupted | Continuous torque transfer |

| Misalignment Handling | Limited tolerance | Designed to accommodate angular, parallel, and axial misalignment |

| Maintenance | Requires regular inspection and possible part replacement (e.g., friction plates) | Generally low maintenance but depends on coupling type |

Introduction to Clutch and Coupling

A clutch is a mechanical device that connects and disconnects the power transmission from the engine to the drivetrain, allowing controlled engagement and disengagement in vehicles. A coupling, on the other hand, connects two shafts together to transmit torque while accommodating misalignment and reducing shock loads in various machinery. Understanding the difference between a clutch and coupling helps you select the right component for efficient power transmission and vehicle control.

Key Differences Between Clutch and Coupling

Clutches and couplings are both mechanical devices used to connect rotating shafts but serve different functions; a clutch allows controlled engagement and disengagement of power transmission, while a coupling provides a permanent or semi-permanent connection transmitting power continuously. Clutches are essential in vehicles for smooth gear shifting by temporarily disconnecting the engine from the drivetrain, whereas couplings accommodate misalignment and reduce transmission of shock loads between connected shafts in machinery. Key differences include the clutch's ability to control motion and torque transfer dynamically versus the coupling's role in maintaining shaft alignment and transmitting torque without interruption.

Working Principles of Clutches

Clutches operate by engaging and disengaging the engine's power to the transmission through friction plates or discs, enabling smooth control of torque transfer. When the clutch pedal is pressed, the pressure plate releases the clutch disc, interrupting the power flow and allowing gear shifts without damaging the transmission. Precise contact between the flywheel, clutch disc, and pressure plate ensures efficient power transmission and prevents slippage during vehicle operation.

Working Principles of Couplings

Couplings transmit torque by connecting two shafts, using mechanical components like flexible elements or rigid mechanisms to accommodate misalignment and reduce vibration. Their working principle relies on the transfer of rotational motion while compensating for slight angular, parallel, or axial misalignments between connected shafts. You benefit from couplings ensuring efficient power transmission and protecting your machinery from damage due to shaft misalignment or shock loads.

Types of Clutches

Clutches are essential automotive components that engage and disengage the power transmission between the engine and the drivetrain. Common types of clutches include friction clutches, such as single plate, multi-plate, and cone clutches, which rely on friction material to transmit torque efficiently. Other specialized clutches include centrifugal and hydraulic clutches, each designed to optimize performance in specific driving conditions or vehicle applications.

Types of Couplings

Gear couplings, flexible couplings, and rigid couplings are the primary types of couplings used in mechanical systems to connect rotating shafts and transmit torque efficiently. Flexible couplings accommodate misalignment and reduce vibration, while gear couplings handle high torque in heavy industrial applications. Understanding these types helps you select the right coupling for optimal machine performance and longevity.

Applications of Clutch and Coupling

Clutches are primarily used in automotive transmissions, heavy machinery, and industrial equipment to engage and disengage power flow between engines and gearboxes, allowing controlled starts and stops. Couplings serve to connect two rotating shafts in pumps, compressors, and conveyor systems, enabling torque transfer while compensating for misalignment and reducing vibration. Both components play critical roles in mechanical power transmission but are selected based on the need for engagement control versus continuous rotational connection.

Advantages and Disadvantages

Clutches offer smooth engagement and easy control over power transmission, making them ideal for starting and stopping engines, but they can wear out quickly and require frequent maintenance. Couplings provide a reliable connection between shafts with minimal maintenance and protect equipment from misalignment or overload, though they lack the ability to engage or disengage power like clutches. Understanding the advantages and disadvantages of clutch and coupling systems helps you select the right component for efficient mechanical performance.

Selection Criteria for Clutch vs Coupling

Selection criteria for clutch versus coupling depend on application requirements such as torque transmission, engagement control, and load type. Clutches are ideal when controlled engagement and disengagement are necessary, especially for variable loads and start-stop motion, whereas couplings excel in connecting two shafts for continuous torque transfer with minimal backlash. Your choice should consider factors like operational speed, alignment tolerance, maintenance needs, and the mechanical environment to ensure optimal performance and longevity.

Clutch vs Coupling: Summary Comparison

Clutches and couplings are mechanical devices used to connect shafts, but clutches enable controlled engagement and disengagement of power transmission, while couplings provide a continuous connection for torque transfer. Clutches are essential in applications requiring start-stop operation or speed variation, allowing your machinery to pause without stopping the entire system. Couplings primarily accommodate misalignment and transmit torque smoothly, ensuring consistent power flow between rotating components.

Clutch vs coupling Infographic

libmatt.com

libmatt.com