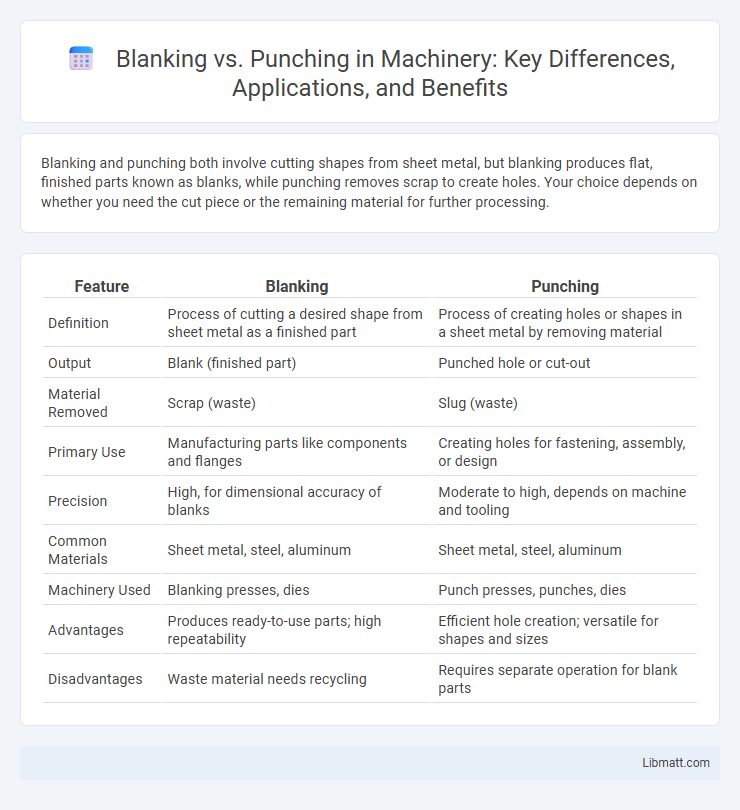

Blanking and punching both involve cutting shapes from sheet metal, but blanking produces flat, finished parts known as blanks, while punching removes scrap to create holes. Your choice depends on whether you need the cut piece or the remaining material for further processing.

Table of Comparison

| Feature | Blanking | Punching |

|---|---|---|

| Definition | Process of cutting a desired shape from sheet metal as a finished part | Process of creating holes or shapes in a sheet metal by removing material |

| Output | Blank (finished part) | Punched hole or cut-out |

| Material Removed | Scrap (waste) | Slug (waste) |

| Primary Use | Manufacturing parts like components and flanges | Creating holes for fastening, assembly, or design |

| Precision | High, for dimensional accuracy of blanks | Moderate to high, depends on machine and tooling |

| Common Materials | Sheet metal, steel, aluminum | Sheet metal, steel, aluminum |

| Machinery Used | Blanking presses, dies | Punch presses, punches, dies |

| Advantages | Produces ready-to-use parts; high repeatability | Efficient hole creation; versatile for shapes and sizes |

| Disadvantages | Waste material needs recycling | Requires separate operation for blank parts |

Introduction to Blanking and Punching

Blanking and punching are metal fabrication processes that involve cutting shapes from sheet metal using a press and die. Blanking removes a desired piece from the larger sheet, often used as the final product, while punching creates holes or cutouts in the sheet, where the removed scrap is typically discarded. Both processes rely on precise tooling and pressure to achieve clean, accurate cuts essential in manufacturing automotive parts, appliances, and electronics.

Definition of Blanking

Blanking is a metalworking process where a sheet metal strip is cut to create a finished part, known as the blank, by removing it from the larger sheet. This technique produces precise shapes with clean edges, typically used as the initial stage before further processing like forming or stamping. Your manufacturing efficiency relies on understanding blanking to optimize material utilization and maintain part accuracy.

Definition of Punching

Punching is a metal fabrication process that involves using a punch press to create holes or shapes in sheet metal by exerting a shearing force that cuts through the material. This operation differs from blanking, which removes a piece entirely from the sheet to produce a desired shape as the final product. Your choice between punching and blanking depends on whether the goal is to produce holes or separate components within metal manufacturing.

Key Differences Between Blanking and Punching

Blanking involves cutting a flat shape from sheet metal to create a finished part, while punching removes scrap material, leaving a hole in the workpiece. The key difference lies in the desired output: blanking produces the usable piece, whereas punching focuses on creating openings within the metal. Your choice depends on whether you need separate components or holes in existing parts.

Process Steps in Blanking

Blanking involves cutting a flat sheet of metal into a desired shape by using a punch and die, where the blanked part is the desired piece removed from the sheet. The process steps in blanking include placing the sheet metal on the die, lowering the punch to shear the material along the die's edge, and ejecting the blanked part for further processing. Your precision in aligning the sheet and maintaining punch sharpness directly affects the quality and accuracy of the blanked components.

Process Steps in Punching

Punching involves positioning the sheet metal between a punch and die, then applying force to shear out a desired shape. The process steps include clamping the material securely, aligning the punch with the die cavity, and driving the punch through the material to create the hole. Ejecting the slug and resetting the punch for subsequent operations completes the cycle efficiently.

Materials Used in Blanking and Punching

Blanking and punching processes handle various materials like metals, including steel, aluminum, and copper alloys, selected based on thickness and application requirements. Blanking typically involves thicker materials to create precise parts, while punching accommodates thinner sheets for hole-making or shaping. Your choice of material impacts tool wear, cutting quality, and overall manufacturing efficiency in both techniques.

Applications of Blanking

Blanking is widely used in manufacturing industries such as automotive, electronics, and appliances for producing precision metal parts like washers, gaskets, and brackets with exact shapes and sizes. This process efficiently handles high-volume production of thin sheet metals, making it ideal for components requiring minimal secondary processing. The ability to create consistent, uniform blanks drives its application in stamping operations and assembly line manufacturing.

Applications of Punching

Punching is widely used in manufacturing industries such as automotive, aerospace, and electronics for creating precise holes and shapes in sheet metal components. This process enables high-speed production of parts like brackets, connectors, and enclosures with repeatable accuracy. Its efficiency in producing complex cutouts and reducing material waste makes punching ideal for large-scale industrial fabrication.

Advantages and Disadvantages of Blanking vs Punching

Blanking produces flat, precise parts ideal for high-volume manufacturing, offering excellent dimensional accuracy and minimal material waste but may require more complex tooling and higher initial costs. Punching excels at creating holes or cutouts quickly with flexible design capabilities and is cost-effective for varied shapes, yet it can generate burrs and may reduce sheet strength around punched areas. Both methods optimize metal fabrication efficiency, with blanking favored for part separation and punching suited for detailed hole patterns.

Blanking vs punching Infographic

libmatt.com

libmatt.com