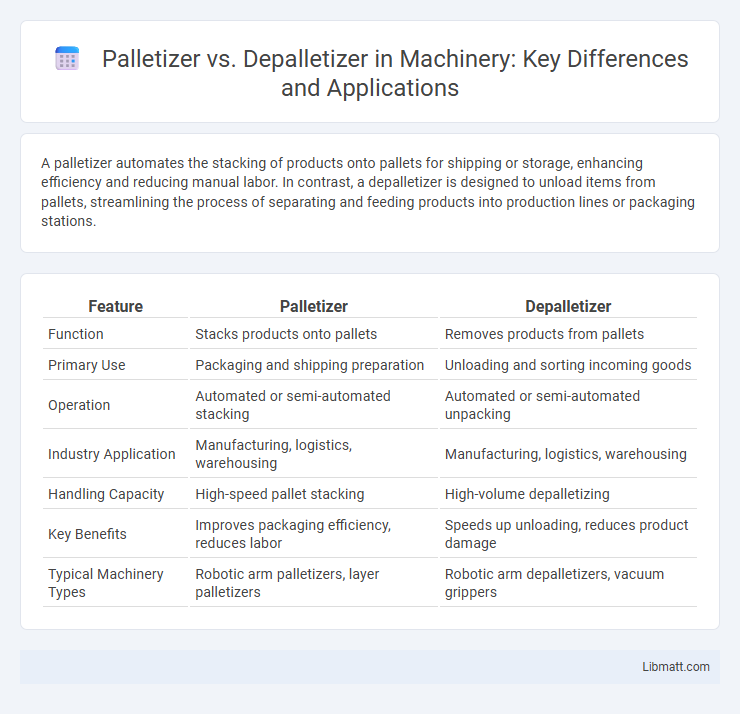

A palletizer automates the stacking of products onto pallets for shipping or storage, enhancing efficiency and reducing manual labor. In contrast, a depalletizer is designed to unload items from pallets, streamlining the process of separating and feeding products into production lines or packaging stations.

Table of Comparison

| Feature | Palletizer | Depalletizer |

|---|---|---|

| Function | Stacks products onto pallets | Removes products from pallets |

| Primary Use | Packaging and shipping preparation | Unloading and sorting incoming goods |

| Operation | Automated or semi-automated stacking | Automated or semi-automated unpacking |

| Industry Application | Manufacturing, logistics, warehousing | Manufacturing, logistics, warehousing |

| Handling Capacity | High-speed pallet stacking | High-volume depalletizing |

| Key Benefits | Improves packaging efficiency, reduces labor | Speeds up unloading, reduces product damage |

| Typical Machinery Types | Robotic arm palletizers, layer palletizers | Robotic arm depalletizers, vacuum grippers |

Introduction to Palletizers and Depalletizers

Palletizers automate the stacking of products onto pallets, enhancing efficiency in packaging and shipping processes by organizing items systematically for transport or storage. Depalletizers perform the inverse function by unloading products from pallets, facilitating smooth integration into production lines or processing units. Both systems are integral to modern material handling, reducing labor costs and minimizing damage during product transition stages.

Defining Palletizer: Function and Purpose

A palletizer is a robotic or automated machine designed to stack products, such as boxes or bags, onto pallets efficiently and uniformly to prepare them for storage or shipment. Its purpose is to streamline the packaging process by increasing speed, reducing manual labor, and minimizing product damage during handling. Understanding your palletizer ensures optimized workflow and maximized output in warehouse or manufacturing settings.

Understanding Depalletizer: Key Role in Automation

A depalletizer plays a crucial role in automation by efficiently unloading products from pallets, streamlining production lines, and reducing manual labor. It uses advanced robotics and sensors to handle various product types with precision, minimizing damage and increasing throughput. Integration of depalletizers enhances workflow continuity and supports real-time inventory management in automated systems.

Types of Palletizers: Manual, Semi-Automatic, and Automatic

Manual, semi-automatic, and automatic palletizers represent key types designed to optimize your material handling processes. Manual palletizers require physical labor for stacking, ideal for low-volume operations, while semi-automatic machines combine some mechanization for efficiency without full automation complexity. Automatic palletizers offer high-speed, fully automated stacking with programmable controls, best suited for large-scale industrial environments where precision and speed are critical.

Depalletizer Variations: Top-Entry, Side-Entry, Robotic

Depalletizers come in various types including top-entry, side-entry, and robotic systems, each designed to efficiently unload products from pallets based on specific operational needs. Top-entry depalletizers are ideal for high-speed, automated lines where products are lifted directly from the top, while side-entry units excel in space-constrained environments by removing layers horizontally. Robotic depalletizers offer flexibility and precision, capable of handling diverse product shapes and sizes with programmable accuracy, making them suitable for complex workflows.

Comparing Workflow Integration: Palletizers vs Depalletizers

Palletizers streamline workflow integration by automating the stacking of products onto pallets for efficient storage or transport, enhancing production line output and reducing manual labor. Depalletizers optimize workflow by automating the removal of products from pallets for processing, packaging, or distribution, increasing throughput and minimizing product damage. Both systems are essential in supply chain automation, improving operational efficiency through precise coordination with conveyor systems, robots, and packaging machinery.

Efficiency and Productivity Analysis

Palletizers significantly enhance efficiency by automating the stacking process, reducing manual labor, and minimizing errors, which results in faster throughput and consistent load stability. Depalletizers improve productivity by streamlining the unloading of goods from pallets, accelerating the handling process, and enabling smooth integration with automated manufacturing or packaging lines. Analyzing efficiency highlights that palletizers optimize space utilization while depalletizers reduce downtime, both crucial for maximizing overall operational productivity in supply chain management.

Safety Considerations for Both Systems

Palletizers and depalletizers require rigorous safety measures due to their heavy machinery and automated operations. Safety features such as emergency stop buttons, light curtains, and proper guarding help prevent accidents during loading and unloading processes. Ensuring regular maintenance and operator training enhances Your protection while handling these systems in industrial settings.

Choosing Between Palletizer and Depalletizer

Choosing between a palletizer and depalletizer depends on your operational needs: palletizers automate stacking products onto pallets while depalletizers handle unloading items from pallets. Your production line efficiency improves by selecting equipment tailored to either loading or unloading tasks, minimizing manual labor and reducing downtime. Consider your workflow, volume requirements, and integration with existing machinery to determine the best fit for your facility.

Future Trends in Palletizing and Depalletizing Technology

Future trends in palletizing and depalletizing technology emphasize increased automation and integration of AI-driven robotics to enhance precision and speed in material handling. Advanced sensors and machine learning algorithms optimize load stability and reduce human error, while collaborative robots (cobots) enable safer, flexible operations in smaller production environments. Energy-efficient systems and IoT connectivity further support real-time monitoring and predictive maintenance, driving cost savings and operational efficiency in supply chain logistics.

Palletizer vs depalletizer Infographic

libmatt.com

libmatt.com