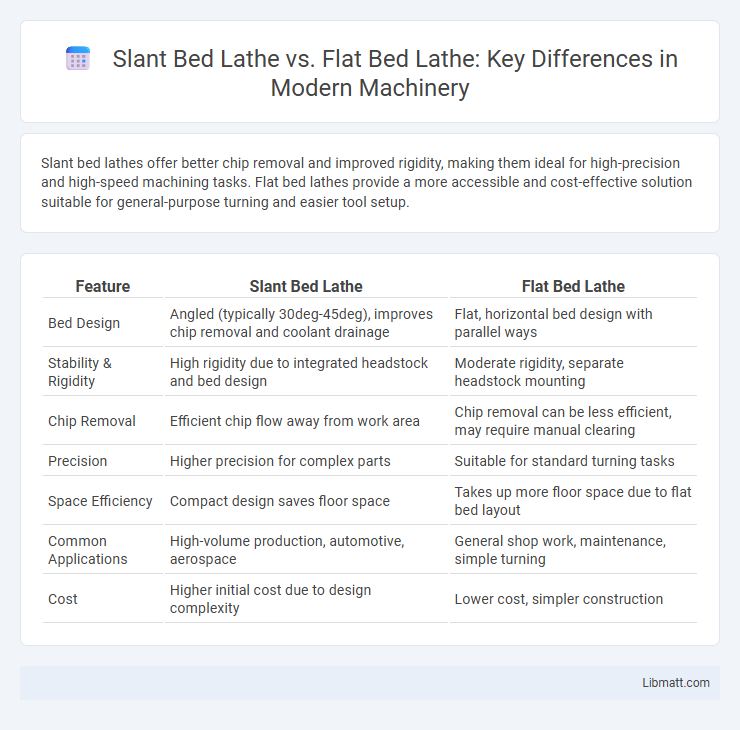

Slant bed lathes offer better chip removal and improved rigidity, making them ideal for high-precision and high-speed machining tasks. Flat bed lathes provide a more accessible and cost-effective solution suitable for general-purpose turning and easier tool setup.

Table of Comparison

| Feature | Slant Bed Lathe | Flat Bed Lathe |

|---|---|---|

| Bed Design | Angled (typically 30deg-45deg), improves chip removal and coolant drainage | Flat, horizontal bed design with parallel ways |

| Stability & Rigidity | High rigidity due to integrated headstock and bed design | Moderate rigidity, separate headstock mounting |

| Chip Removal | Efficient chip flow away from work area | Chip removal can be less efficient, may require manual clearing |

| Precision | Higher precision for complex parts | Suitable for standard turning tasks |

| Space Efficiency | Compact design saves floor space | Takes up more floor space due to flat bed layout |

| Common Applications | High-volume production, automotive, aerospace | General shop work, maintenance, simple turning |

| Cost | Higher initial cost due to design complexity | Lower cost, simpler construction |

Introduction to Slant Bed and Flat Bed Lathes

Slant bed lathes feature a tilted bed design that enhances chip removal and improves tool visibility, making them ideal for high-precision and heavy-duty machining operations. Flat bed lathes have a horizontal bed that offers greater stability and consistent alignment, preferred for traditional turning tasks and simpler setups. Both lathe types serve distinct industrial needs, with slant beds favored in automotive and aerospace manufacturing and flat beds common in general metalworking.

Design Differences: Slant Bed vs Flat Bed

Slant bed lathes feature an inclined bed that allows better chip removal and easier tool access, enhancing machining precision and operator comfort. Flat bed lathes have a horizontal bed design that offers simpler construction and stability for heavy, straight turning tasks. The slant bed's angled structure reduces tool post overhang and improves rigidity, while flat beds provide a more straightforward layout suited for large or heavy workpieces.

Precision and Accuracy Comparison

Slant bed lathes offer enhanced precision and accuracy due to their inclined bed design, which reduces tool deflection and vibration during machining. Flat bed lathes tend to exhibit more tool chatter and less stability, impacting dimensional accuracy in high-tolerance tasks. The slant bed's improved structural rigidity makes it ideal for precision engineering applications requiring tight tolerances.

Material Handling and Workpiece Size Capabilities

Slant bed lathes offer superior material handling with inclined beds that facilitate gravity-assisted chip removal and better access to larger, heavier workpieces, enhancing machining efficiency for bulky components. Flat bed lathes, featuring a horizontal bed design, are typically suited for smaller to medium-sized workpieces but may require more manual intervention for heavy or large materials due to limited chip evacuation. The slant bed's ergonomic design supports higher rigidity and stability, enabling it to accommodate sizable workpieces with improved precision compared to flat bed lathes.

Space and Floor Requirements

Slant bed lathes require less floor space due to their inclined design, which allows for more compact setups and easier access to workpieces. Flat bed lathes have a horizontal bed that demands a larger footprint, making them less suitable for workshops with limited space. Your choice between the two must consider available floor area and desired workspace efficiency.

Maintenance and Durability

Slant bed lathes feature an inclined bed design that promotes better chip flow and reduces wear on ways, resulting in lower maintenance requirements and enhanced durability compared to flat bed lathes. The flat bed lathe's horizontal bed exposes guides to more direct wear and tear, necessitating more frequent lubrication and adjustments. Slant bed lathes often incorporate harder, more wear-resistant materials for their guideways, extending machine life and reducing downtime in industrial applications.

Versatility and Application Suitability

Slant bed lathes offer enhanced rigidity and better chip evacuation, making them highly versatile for heavy-duty and high-precision machining tasks, especially in automotive and aerospace industries. Flat bed lathes are more suitable for conventional, general-purpose turning operations with ease of tool setup and maintenance, ideal for smaller workshops or simpler production runs. The choice between slant bed and flat bed lathes depends largely on the complexity, volume, and precision requirements of the application.

Cost Analysis: Upfront and Operational Expenses

Slant bed lathes typically have a higher upfront cost compared to flat bed lathes due to their advanced design and better chip removal capabilities, which can enhance productivity and reduce downtime. Operational expenses for slant bed lathes tend to be lower over time because of improved tool life and maintenance efficiency, while flat bed lathes may incur higher long-term costs due to increased wear and slower chip evacuation. Evaluating your production needs and budget constraints will help determine which lathe offers the best balance between initial investment and ongoing operational savings.

User Experience and Safety Features

Slant bed lathes provide enhanced user experience through improved ergonomics by positioning the spindle at an angle, reducing operator fatigue and offering better visibility of the workpiece compared to flat bed lathes. Safety features on slant bed lathes often include integrated chip guards and emergency stop buttons within easy reach, promoting a safer working environment. Your operation benefits from reduced risk of accidents and increased precision, making slant bed lathes ideal for complex machining tasks where safety and comfort are paramount.

Choosing the Right Lathe for Your Workshop

Selecting the right lathe depends on your workshop's specific needs: slant bed lathes offer better chip clearance and rigidity, making them ideal for heavy-duty machining and precision work. Flat bed lathes provide versatility and easier access for tool adjustment, suitable for general-purpose tasks and larger workpieces. Evaluating factors like workspace size, material type, and production volume ensures optimal lathe performance and efficiency.

Slant bed lathe vs flat bed lathe Infographic

libmatt.com

libmatt.com