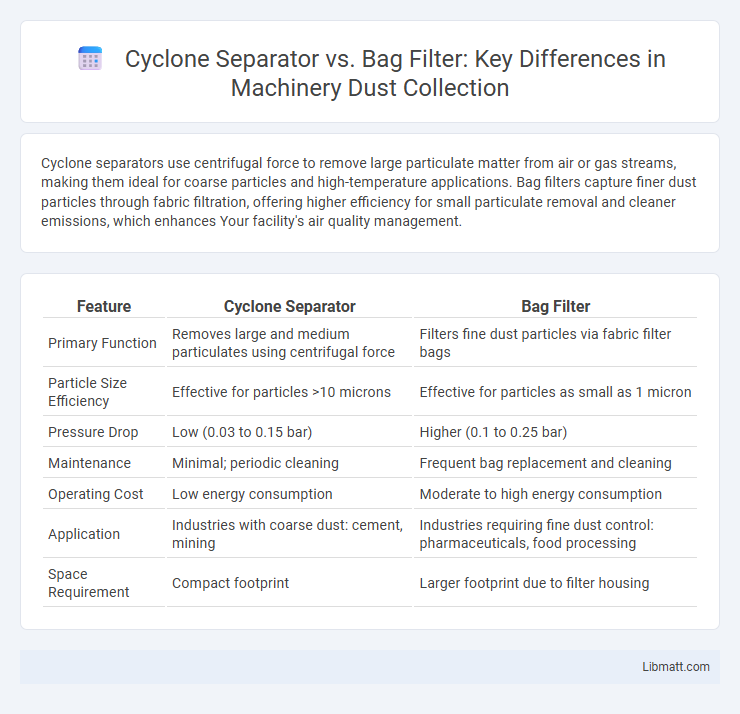

Cyclone separators use centrifugal force to remove large particulate matter from air or gas streams, making them ideal for coarse particles and high-temperature applications. Bag filters capture finer dust particles through fabric filtration, offering higher efficiency for small particulate removal and cleaner emissions, which enhances Your facility's air quality management.

Table of Comparison

| Feature | Cyclone Separator | Bag Filter |

|---|---|---|

| Primary Function | Removes large and medium particulates using centrifugal force | Filters fine dust particles via fabric filter bags |

| Particle Size Efficiency | Effective for particles >10 microns | Effective for particles as small as 1 micron |

| Pressure Drop | Low (0.03 to 0.15 bar) | Higher (0.1 to 0.25 bar) |

| Maintenance | Minimal; periodic cleaning | Frequent bag replacement and cleaning |

| Operating Cost | Low energy consumption | Moderate to high energy consumption |

| Application | Industries with coarse dust: cement, mining | Industries requiring fine dust control: pharmaceuticals, food processing |

| Space Requirement | Compact footprint | Larger footprint due to filter housing |

Introduction to Cyclone Separators and Bag Filters

Cyclone separators utilize centrifugal force to remove large particulate matter from gas streams, making them highly effective for pre-cleaning in industrial applications. Bag filters rely on fabric filter media to capture fine dust particles with high efficiency, commonly used in industries requiring stringent air pollution control. Both technologies serve crucial roles in dust collection systems, with cyclones handling coarse particles and bag filters targeting finer emissions.

Working Principles: Cyclone Separator vs Bag Filter

Cyclone separators use centrifugal force to remove large particulate matter from gas streams by spinning the air and forcing heavier particles to the outer wall for collection. Bag filters operate by passing dust-laden air through fabric filter bags that trap fine particles within the fibers as air flows through. Your choice between a cyclone separator and a bag filter depends on particle size and filtration efficiency required, with cyclones suited for larger particles and bag filters effective for fine dust removal.

Key Components of Cyclone Separators

Cyclone separators consist primarily of a cylindrical body, a conical section, and a tangential inlet that generates a vortex for particle separation. The vortex finder at the top allows clean gas to exit while centrifugal forces push particulate matter to the walls for collection. Key components also include the dust collection chamber and the outlet for separated solids, enabling efficient removal of coarse particles from air or gas streams.

Key Components of Bag Filters

Bag filters consist of filter bags, a casing, and a cleaning system, which together capture fine particles from industrial air streams. The filter bags are typically made from woven or non-woven fabric, offering high filtration efficiency for dust and pollutants. Understanding these key components helps you optimize filtration performance and ensure cleaner air emissions.

Efficiency Comparison: Cyclone Separator vs Bag Filter

Cyclone separators typically achieve dust removal efficiencies of 50-90% for particles larger than 10 microns, making them suitable for coarse particulate matter. Bag filters provide superior efficiency rates, often exceeding 99.9% for fine particles down to 1 micron or smaller, capturing even the most corrosive and hazardous dust types. Selecting the right system depends on your specific particle size distribution and required air quality standards.

Application Areas in Industry

Cyclone separators are widely used in industries such as cement, steel, and power plants to remove large particulate matter from gas streams, offering high efficiency for coarse dust collection. Bag filters excel in applications requiring fine dust filtration, including pharmaceuticals, food processing, and chemical manufacturing, ensuring cleaner emissions and product integrity. Your choice depends on the specific particle size and industry requirements for air pollution control and material recovery.

Maintenance and Operational Costs

Cyclone separators have lower maintenance and operational costs due to their simple design and lack of filter media replacement, making them ideal for handling large volumes of coarse particles. Bag filters require regular replacement of filter bags and periodic cleaning, which increases both labor and material expenses over time. You should consider cyclone separators for cost-effective, low-maintenance dust collection in industrial applications with heavier particulate loads.

Advantages and Limitations

Cyclone separators offer high durability and low maintenance by using centrifugal force to remove large particulate matter from air streams, making them ideal for industries with abrasive dust. Bag filters provide superior filtration efficiency by capturing fine particles using fabric media, ensuring better air quality but requiring regular cleaning and replacement of filter bags. You should consider cyclone separators for cost-effective pre-filtration and bag filters when compliance with stringent emission standards is essential.

Environmental Impact and Compliance

Cyclone separators offer lower environmental impact by reducing particulate emissions with minimal energy consumption and no need for disposable filter media, ensuring efficient compliance with air quality standards. Bag filters provide higher filtration efficiency for fine particles but generate waste through spent filter bags, requiring proper disposal to maintain regulatory adherence. Your choice between cyclone separators and bag filters depends on balancing emission control goals with environmental sustainability and compliance requirements.

Choosing the Right Dust Collection System

Choosing the right dust collection system depends on the particle size and dust concentration, where cyclone separators excel in removing large, coarse particles using centrifugal force, making them ideal for heavy dust loads. Bag filters provide higher filtration efficiency for fine dust by capturing particles on fabric bags, suitable for applications requiring precise air quality control. Evaluating factors such as maintenance costs, airflow requirements, and regulatory compliance ensures optimal system performance and longevity.

Cyclone separator vs bag filter Infographic

libmatt.com

libmatt.com