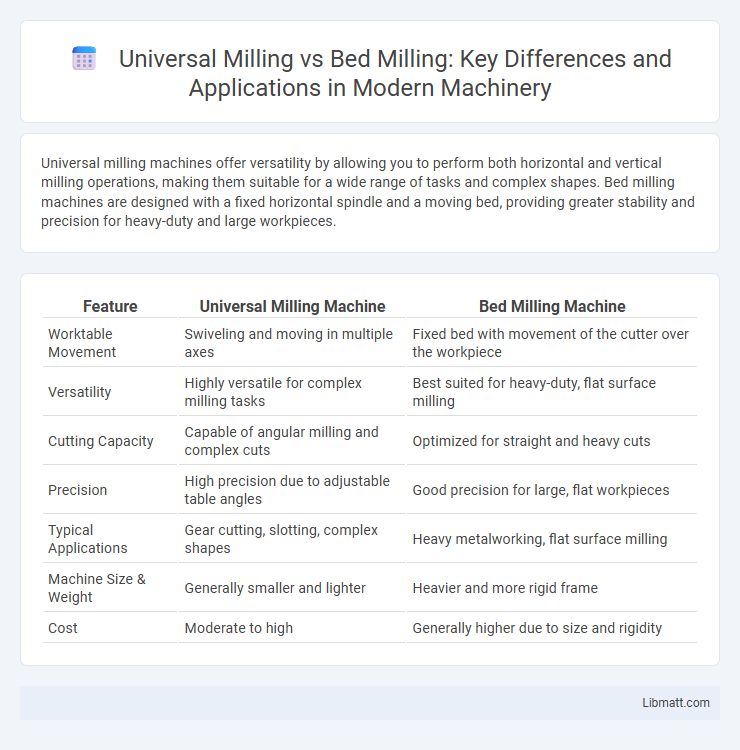

Universal milling machines offer versatility by allowing you to perform both horizontal and vertical milling operations, making them suitable for a wide range of tasks and complex shapes. Bed milling machines are designed with a fixed horizontal spindle and a moving bed, providing greater stability and precision for heavy-duty and large workpieces.

Table of Comparison

| Feature | Universal Milling Machine | Bed Milling Machine |

|---|---|---|

| Worktable Movement | Swiveling and moving in multiple axes | Fixed bed with movement of the cutter over the workpiece |

| Versatility | Highly versatile for complex milling tasks | Best suited for heavy-duty, flat surface milling |

| Cutting Capacity | Capable of angular milling and complex cuts | Optimized for straight and heavy cuts |

| Precision | High precision due to adjustable table angles | Good precision for large, flat workpieces |

| Typical Applications | Gear cutting, slotting, complex shapes | Heavy metalworking, flat surface milling |

| Machine Size & Weight | Generally smaller and lighter | Heavier and more rigid frame |

| Cost | Moderate to high | Generally higher due to size and rigidity |

Introduction to Universal Milling and Bed Milling

Universal milling machines feature adjustable heads and tables that allow for versatile machining of complex parts across multiple axes, enhancing precision and efficiency. Bed milling machines provide a sturdy design with a fixed table, ideal for heavy-duty cutting and large workpieces requiring rigid stability. Understanding your specific machining needs helps determine whether the versatility of universal milling or the robust support of bed milling best suits your operations.

Key Features of Universal Milling Machines

Universal milling machines offer versatile spindle capabilities and adjustable table movement, enabling complex machining tasks like angular cutting and helical milling. Their ability to tilt the spindle and swivel the table provides enhanced precision and flexibility compared to bed milling machines, which have a fixed spindle position. Understanding these key features helps you choose the right machine for diverse manufacturing needs and improved efficiency.

Key Features of Bed Milling Machines

Bed milling machines feature a rigid, heavy-duty table fixed to the base, providing excellent stability and precision for heavy cutting tasks. Their design supports large workpieces and allows for straightforward setup and adjustment, making them ideal for high-accuracy machining in industries like aerospace and automotive. Your choice of a bed milling machine ensures enhanced durability and consistent performance in demanding milling operations.

Differences in Design and Construction

Universal milling machines feature a versatile design with a swivel-type table that allows multi-axis movement, enabling angular cuts and complex machining operations. Bed milling machines have a fixed bed design where the workpiece remains stationary, and only the cutter moves along the X, Y, and Z axes, offering rigidity suited for heavy-duty milling. The construction of universal milling machines incorporates adjustable head and table components for diverse machining angles, whereas bed milling machines prioritize stability with a large, robust bed supporting fixed tables.

Versatility and Applications

Universal milling machines offer greater versatility with the capability to perform various operations such as face milling, angular milling, and slotting, making them suitable for complex and diverse tasks. Bed milling machines provide higher stability and precision, ideal for heavy-duty and large workpieces, especially in industries requiring consistent, repeatable milling processes. Your choice depends on whether you prioritize multifunctional use or specialized, high-precision milling applications.

Precision and Accuracy Comparison

Universal milling machines provide enhanced flexibility and accuracy through their adjustable heads and multiple axis movements, allowing for precise machining of complex shapes. Bed milling machines excel in rigidity and stability, delivering consistent precision for heavy-duty operations on flat surfaces. Choose your milling machine based on the specific precision requirements of your machining tasks to ensure optimal accuracy.

Efficiency and Productivity

Universal milling machines offer enhanced efficiency and productivity with their versatile spindle orientation, enabling both horizontal and vertical milling without changing setups. Bed milling machines provide robust stability and precise workholding, which improves machining accuracy for heavy-duty tasks but limits flexibility. The universal milling's adaptability reduces downtime and tooling changes, making it more suitable for varied production demands.

Cost Considerations

Universal milling machines generally incur higher initial costs due to their versatile capabilities and more complex construction compared to bed milling machines, which are typically more affordable and suited for simpler tasks. Operating expenses for universal milling can increase because of the need for skilled operators and more frequent maintenance to handle varied machining processes. Bed milling machines offer cost advantages for repetitive, less complex jobs by minimizing setup times and reducing tool wear, resulting in lower long-term operational costs.

Maintenance and Durability

Universal milling machines require frequent maintenance due to their complex mechanisms and multiple axis movements, which can lead to higher wear and tear on components. Bed milling machines offer greater durability with a robust, rigid construction and fewer moving parts, resulting in lower maintenance costs and longer service life. Regular lubrication and timely replacement of critical parts are essential for both types to ensure optimal performance and longevity.

Choosing the Right Milling Machine for Your Needs

Universal milling machines offer versatile capabilities with adjustable tables and multiple axis movements, ideal for complex and varied machining tasks requiring flexibility. Bed milling machines provide a rigid and stable platform suitable for heavy-duty and large workpieces, ensuring precision in repetitive operations. Selecting the right milling machine depends on the complexity of parts, production volume, and material characteristics to optimize efficiency and accuracy.

Universal milling vs bed milling Infographic

libmatt.com

libmatt.com