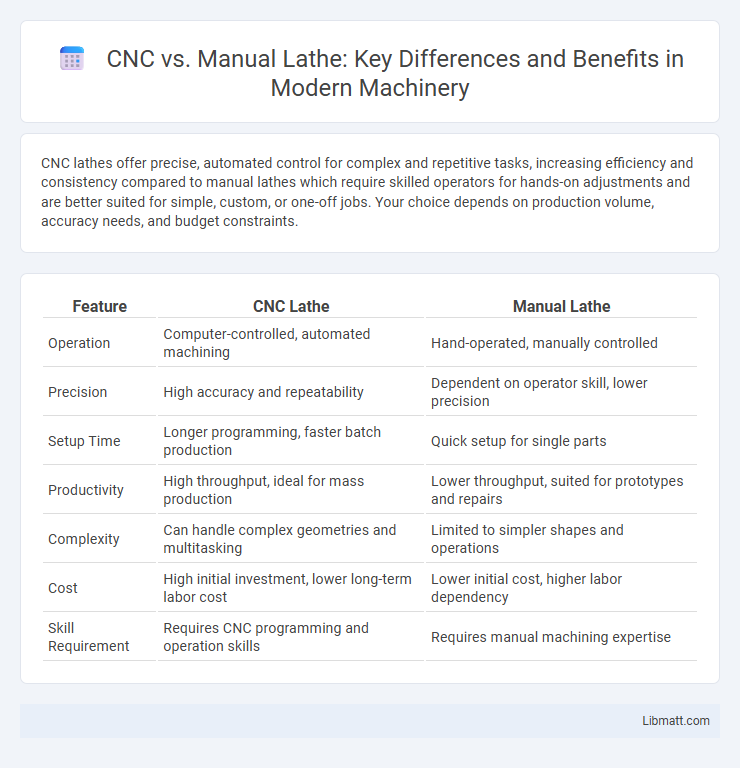

CNC lathes offer precise, automated control for complex and repetitive tasks, increasing efficiency and consistency compared to manual lathes which require skilled operators for hands-on adjustments and are better suited for simple, custom, or one-off jobs. Your choice depends on production volume, accuracy needs, and budget constraints.

Table of Comparison

| Feature | CNC Lathe | Manual Lathe |

|---|---|---|

| Operation | Computer-controlled, automated machining | Hand-operated, manually controlled |

| Precision | High accuracy and repeatability | Dependent on operator skill, lower precision |

| Setup Time | Longer programming, faster batch production | Quick setup for single parts |

| Productivity | High throughput, ideal for mass production | Lower throughput, suited for prototypes and repairs |

| Complexity | Can handle complex geometries and multitasking | Limited to simpler shapes and operations |

| Cost | High initial investment, lower long-term labor cost | Lower initial cost, higher labor dependency |

| Skill Requirement | Requires CNC programming and operation skills | Requires manual machining expertise |

Introduction to CNC and Manual Lathes

CNC lathes utilize computer numerical control to automate precision machining, offering high repeatability and complex shaping capabilities. Manual lathes require skilled operators to physically control cutting tools, making them ideal for custom, low-volume production or prototyping. Your choice depends on production scale, precision needs, and flexibility requirements.

Key Differences Between CNC and Manual Lathes

CNC lathes operate using computer numerical control, allowing for precise, automated machining of complex parts with minimal human intervention, while manual lathes rely entirely on operator skill for tool movement and adjustments. CNC lathes offer higher repeatability, faster production rates, and better consistency in large-scale manufacturing compared to manual lathes, which are more suited for simple, low-volume tasks or prototype work. Maintenance and training requirements differ significantly, with CNC machines demanding specialized programming knowledge and maintenance, whereas manual lathes involve more direct mechanical skill and manual oversight.

Precision and Accuracy: CNC vs Manual

CNC lathes offer superior precision and accuracy due to computer-controlled movements that minimize human error, achieving tight tolerances consistently. Manual lathes rely heavily on the operator's skill, which can lead to variability in measurements and less repeatable results. Your choice affects the quality and consistency of parts, especially in high-volume or intricate machining tasks.

Speed and Efficiency Comparison

CNC lathes offer significantly higher speed and efficiency compared to manual lathes by automating precise cutting processes and enabling rapid production cycles with minimal human intervention. Your manufacturing workflow benefits from CNC technology's ability to execute complex, repetitive tasks consistently, reducing downtime and increasing throughput. Manual lathes require skilled operators for each operation, resulting in slower production and potential variability in output quality.

Skill Level and Training Requirements

CNC lathes require operators to have strong computer programming skills and familiarity with CAD/CAM software, whereas manual lathes demand hands-on experience and mechanical aptitude for precise control. Training for CNC involves learning complex software and machine operation, often through formal education or certification programs. Your ability to quickly adapt to CNC technology can significantly enhance efficiency compared to the traditional skillset needed for manual lathe machining.

Cost Considerations: Upfront and Operational

CNC lathes have higher upfront costs due to advanced technology, programming requirements, and automation systems, whereas manual lathes are significantly cheaper initially. Operational costs for CNC machines include maintenance of electronic components, software updates, and skilled operator wages, but they offer improved efficiency and reduced labor time compared to manual lathes. Manual lathes incur lower ongoing expenses but often require more time and skilled manual labor, leading to higher long-term operational costs in high-volume production.

Flexibility and Versatility in Machining

CNC lathes offer superior flexibility and versatility in machining by enabling automated, programmable operations that can produce complex geometries with high precision across multiple materials. Manual lathes rely heavily on operator skill for adjustments, limiting the ability to quickly switch between diverse tasks or replicate intricate designs consistently. CNC technology supports rapid prototyping and efficient production runs, making it ideal for varied machining requirements compared to the more labor-intensive manual lathe processes.

Maintenance and Longevity

CNC lathes require regular software updates and precise calibration to maintain optimal performance, while manual lathes rely heavily on routine mechanical maintenance such as lubrication and alignment checks. The longevity of a CNC lathe is often extended through predictive maintenance and real-time monitoring systems, which help prevent unexpected breakdowns. Your choice should consider that manual lathes may have longer lifespans with proper care, but CNC machines offer enhanced durability by minimizing human error.

Application Suitability: When to Choose CNC or Manual

CNC lathes excel in high-precision, complex, and repetitive manufacturing tasks, making them ideal for mass production and intricate component fabrication with tight tolerances. Manual lathes are suitable for customized, low-volume projects, prototyping, and situations requiring hands-on control or adjustments. Your choice depends on production scale, complexity, and flexibility needs, with CNC offering automation and consistency, while manual provides versatility and direct operator input.

Final Thoughts: Which Lathe is Right for You?

Choosing between a CNC lathe and a manual lathe depends on production scale, precision requirements, and budget. CNC lathes offer superior accuracy, repeatability, and efficiency for complex or high-volume jobs, while manual lathes provide cost-effective control for simpler, low-volume, or prototype work. Evaluating factors like material type, operator skill, and project complexity helps determine the optimal lathe for specific manufacturing needs.

CNC vs manual lathe Infographic

libmatt.com

libmatt.com