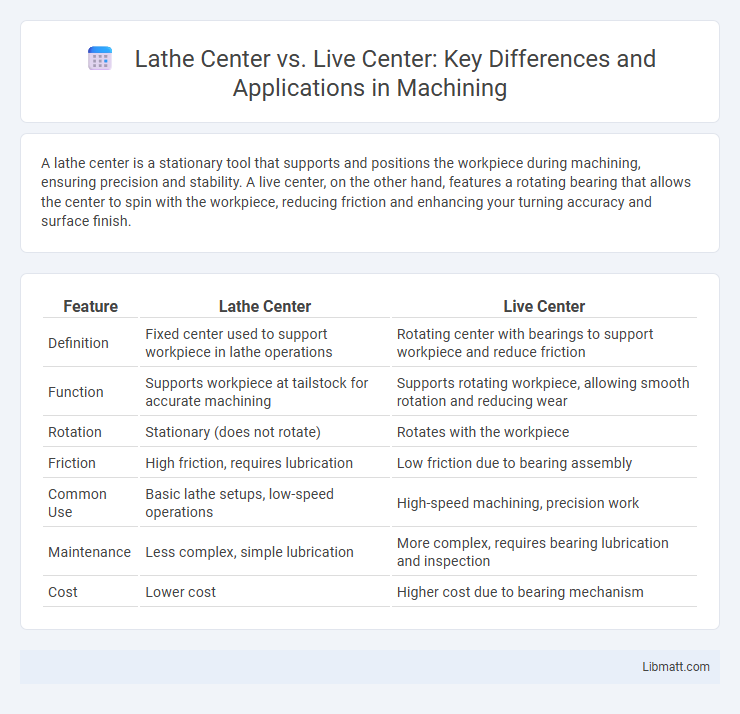

A lathe center is a stationary tool that supports and positions the workpiece during machining, ensuring precision and stability. A live center, on the other hand, features a rotating bearing that allows the center to spin with the workpiece, reducing friction and enhancing your turning accuracy and surface finish.

Table of Comparison

| Feature | Lathe Center | Live Center |

|---|---|---|

| Definition | Fixed center used to support workpiece in lathe operations | Rotating center with bearings to support workpiece and reduce friction |

| Function | Supports workpiece at tailstock for accurate machining | Supports rotating workpiece, allowing smooth rotation and reducing wear |

| Rotation | Stationary (does not rotate) | Rotates with the workpiece |

| Friction | High friction, requires lubrication | Low friction due to bearing assembly |

| Common Use | Basic lathe setups, low-speed operations | High-speed machining, precision work |

| Maintenance | Less complex, simple lubrication | More complex, requires bearing lubrication and inspection |

| Cost | Lower cost | Higher cost due to bearing mechanism |

Introduction to Lathe Centers

Lathe centers are essential tools used in machining to support workpieces during turning operations, ensuring precision and stability. A lathe center fits into the spindle or tailstock and can be classified into dead centers, which remain stationary, and live centers, which rotate with the workpiece to reduce friction. Understanding the differences between a lathe center and a live center helps you optimize tool performance and achieve accurate, consistent results in metalworking tasks.

Overview of Live Centers

Live centers contain bearings that allow the center to rotate with the workpiece, reducing friction and heat during machining. They provide precise support in CNC turning and lathe operations, enhancing accuracy and surface finish. Unlike dead centers, live centers enable higher speeds and longer tool life by minimizing wear on both the center and the workpiece.

Key Differences Between Lathe Centers and Live Centers

Lathe centers serve as fixed supports that hold the workpiece firmly along the spindle axis, while live centers rotate with the workpiece to reduce friction and prevent damage. A lathe center requires manual lubrication and is generally used for less demanding applications, whereas a live center contains bearings that allow smooth rotation and higher precision. Understanding these key differences ensures Your machining process achieves optimal accuracy and efficiency.

Construction and Design Comparison

A lathe center is typically a fixed, hardened steel component designed with a sharp conical point to support the workpiece, ensuring precision during machining; it lacks rotational capability and remains stationary in the tailstock. In contrast, a live center incorporates bearings within its design, enabling the center to rotate with the workpiece, reducing friction and heat buildup for smoother operation and extended tool life. Your choice between these centers depends on the machining requirements, where live centers offer superior performance for high-speed or delicate work due to their rotating design, whereas lathe centers are preferred for rigid, non-rotational support.

Performance and Precision

Lathe centers and live centers differ significantly in performance and precision due to their design and application. A lathe center, typically a dead center, provides rigid support without rotation, offering high precision but increased friction, while a live center incorporates bearings allowing it to rotate with the workpiece, reducing friction and heat buildup to enhance machining accuracy. Your choice between the two impacts the quality of workpiece alignment and surface finish during turning operations.

Typical Applications and Use Cases

Lathe centers are typically used in turning operations to support and accurately position workpieces, ensuring stability during machining of long, slender parts. Live centers are preferred in high-speed or precision applications where reducing friction and heat buildup is critical, such as in CNC machining or delicate finishing tasks. Both devices play crucial roles in metalworking, but live centers provide rotation to minimize workpiece damage while lathe centers remain stationary.

Advantages of Lathe Centers

Lathe centers provide precise support for workpieces during machining, ensuring minimal runout and maintaining concentricity, which enhances the accuracy of turning operations. They are designed to handle high loads and reduce vibration, leading to improved surface finish and longer tool life. Your machining efficiency increases with lathe centers by maintaining stable and rigid positioning throughout the process.

Benefits of Live Centers

Live centers reduce friction during machining by rotating with the workpiece, which minimizes heat buildup and extends tool life. Your workpiece experiences increased stability and precision, improving overall machining accuracy and surface finish. These benefits make live centers essential for high-speed and prolonged lathe operations.

Selection Criteria: When to Use Each Center

Selecting between a lathe center and a live center depends on the workpiece material, machining speed, and required precision. A lathe center is ideal for low-speed operations with abrasive materials, providing firm support but requiring regular lubrication to reduce friction. Your choice should favor a live center when high rotational speeds and reduced heat buildup are critical, as it incorporates bearings that allow the center to rotate with the workpiece, minimizing wear and improving accuracy.

Conclusion and Expert Recommendations

Choosing between a lathe center and a live center depends on your machining precision and efficiency needs; live centers reduce friction by rotating with the workpiece, enhancing tool life and surface finish. Experts recommend using live centers for high-speed, precision turning to improve your lathe's performance, while lathe centers are suitable for lower-speed or less demanding operations. Investing in a quality live center can significantly increase workpiece accuracy and extend tool longevity.

Lathe center vs live center Infographic

libmatt.com

libmatt.com