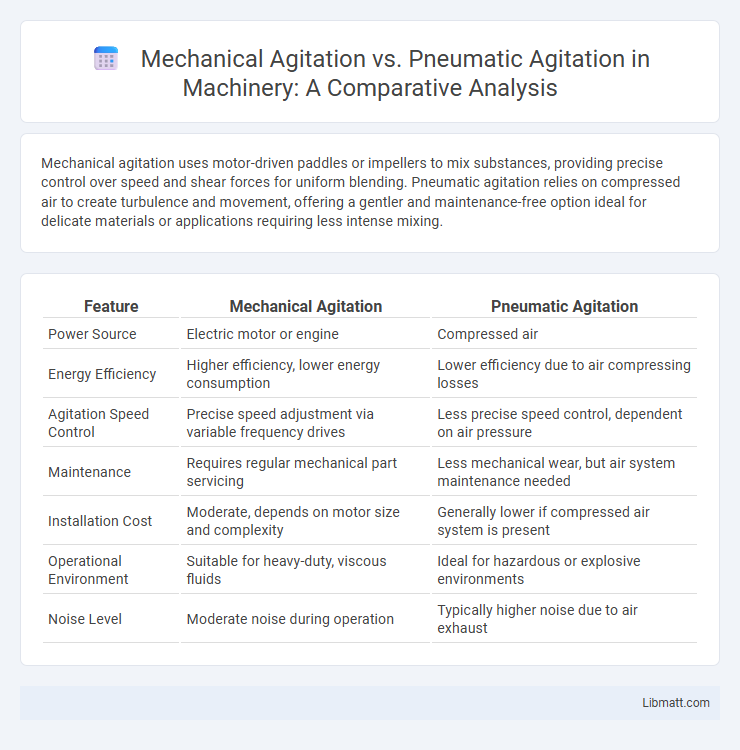

Mechanical agitation uses motor-driven paddles or impellers to mix substances, providing precise control over speed and shear forces for uniform blending. Pneumatic agitation relies on compressed air to create turbulence and movement, offering a gentler and maintenance-free option ideal for delicate materials or applications requiring less intense mixing.

Table of Comparison

| Feature | Mechanical Agitation | Pneumatic Agitation |

|---|---|---|

| Power Source | Electric motor or engine | Compressed air |

| Energy Efficiency | Higher efficiency, lower energy consumption | Lower efficiency due to air compressing losses |

| Agitation Speed Control | Precise speed adjustment via variable frequency drives | Less precise speed control, dependent on air pressure |

| Maintenance | Requires regular mechanical part servicing | Less mechanical wear, but air system maintenance needed |

| Installation Cost | Moderate, depends on motor size and complexity | Generally lower if compressed air system is present |

| Operational Environment | Suitable for heavy-duty, viscous fluids | Ideal for hazardous or explosive environments |

| Noise Level | Moderate noise during operation | Typically higher noise due to air exhaust |

Introduction to Agitation Methods

Mechanical agitation uses a motor-driven impeller to create fluid motion, providing consistent and controllable mixing ideal for viscous liquids and large tanks. Pneumatic agitation relies on compressed air to generate turbulence, offering a lower maintenance solution suitable for hazardous or sterile environments where contamination must be minimized. Your choice between these methods depends on factors like process requirements, tank size, and the need for precise control or hygiene.

What is Mechanical Agitation?

Mechanical agitation involves the use of motor-driven impellers or mixers to stir fluids or solids within a vessel, providing consistent and controlled mixing. It offers precise control over speed, torque, and shear, making it suitable for applications requiring uniform blending, heat transfer, or suspension of particles. Your choice of mechanical agitation ensures efficient process control in industries such as pharmaceuticals, food processing, and chemical manufacturing.

What is Pneumatic Agitation?

Pneumatic agitation uses compressed air to create movement within liquids or slurries, promoting uniform mixing without mechanical parts inside the tank. This method reduces maintenance by eliminating agitator shafts and bearings while providing efficient oxygen transfer for processes like fermentation. Compared to mechanical agitation, pneumatic agitation offers improved hygiene and lower contamination risk due to its sealed system design.

Core Principles of Mechanical Agitation

Mechanical agitation relies on rotating impellers or paddles to generate turbulent flow and ensure uniform mixing of liquids or solids within a vessel. This method provides precise control over mixing intensity, shear rates, and flow patterns, making it ideal for processes requiring consistent agitation. Your choice of mechanical agitation impacts energy efficiency and mixing performance, especially in applications like chemical reactors or fermentation.

Core Principles of Pneumatic Agitation

Pneumatic agitation operates on the core principle of using compressed air or gas to induce fluid motion and mixing within a vessel. It relies on the injection of air bubbles or gas streams that create turbulence and enhance mass transfer without direct mechanical contact. This method is especially effective in promoting oxygen transfer in bioreactors while minimizing contamination risks and mechanical wear compared to mechanical agitation.

Comparative Efficiency Analysis

Mechanical agitation offers precise control over mixing speed and intensity, resulting in higher energy efficiency and uniform particle dispersion in various industrial processes. Pneumatic agitation relies on compressed air to induce motion, which can lead to higher operational costs due to air compressor energy consumption and less consistent mixing quality. Studies indicate mechanical agitation systems achieve up to 30% better energy utilization and improved process scalability compared to pneumatic counterparts in chemical and pharmaceutical manufacturing.

Energy Consumption: Mechanical vs Pneumatic

Mechanical agitation typically consumes less energy than pneumatic agitation because it converts electrical power directly into mechanical motion with higher efficiency. Pneumatic agitation relies on compressed air systems, which often experience significant energy loss during air compression and distribution, leading to higher overall energy consumption. Your choice between the two should consider operational energy costs and efficiency for optimal resource management.

Maintenance and Operational Complexity

Mechanical agitation systems require regular maintenance of moving parts such as shafts, bearings, and seals, leading to higher operational complexity due to potential wear and tear. Pneumatic agitation offers simpler maintenance with fewer mechanical components prone to failure, reducing downtime and service efforts. However, pneumatic systems depend on compressed air supply quality and pressure control, adding operational considerations for efficient agitation performance.

Ideal Applications for Each Agitation Type

Mechanical agitation excels in applications requiring precise control and consistent shearing, such as in chemical reactors, fermentation tanks, and large-scale mixing processes involving viscous fluids. Pneumatic agitation is ideal for environments with explosion hazards or where contamination must be minimized, commonly used in pharmaceutical, food processing, and wastewater treatment industries. Selecting between mechanical and pneumatic agitation depends on factors like fluid properties, operational safety standards, and desired mixing intensity.

Choosing the Right Agitation Method

Mechanical agitation offers precise control over mixing speeds and torques, making it ideal for processes requiring consistent shear and uniformity. Pneumatic agitation provides simplicity, lower maintenance, and operation in hazardous environments due to its explosion-proof nature. Selecting the right agitation method depends on your application's viscosity, temperature, and safety requirements to optimize performance and cost-efficiency.

Mechanical agitation vs pneumatic agitation Infographic

libmatt.com

libmatt.com