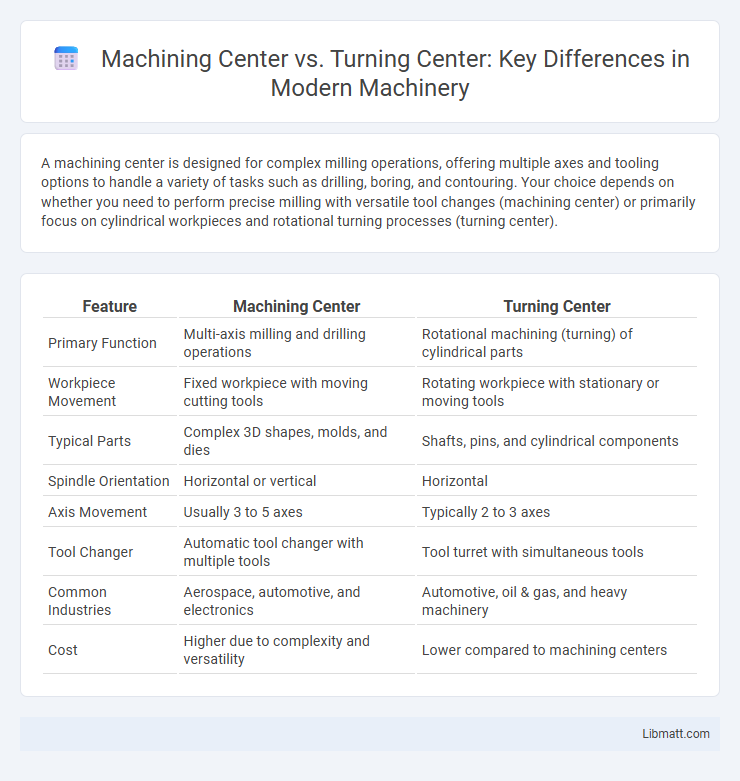

A machining center is designed for complex milling operations, offering multiple axes and tooling options to handle a variety of tasks such as drilling, boring, and contouring. Your choice depends on whether you need to perform precise milling with versatile tool changes (machining center) or primarily focus on cylindrical workpieces and rotational turning processes (turning center).

Table of Comparison

| Feature | Machining Center | Turning Center |

|---|---|---|

| Primary Function | Multi-axis milling and drilling operations | Rotational machining (turning) of cylindrical parts |

| Workpiece Movement | Fixed workpiece with moving cutting tools | Rotating workpiece with stationary or moving tools |

| Typical Parts | Complex 3D shapes, molds, and dies | Shafts, pins, and cylindrical components |

| Spindle Orientation | Horizontal or vertical | Horizontal |

| Axis Movement | Usually 3 to 5 axes | Typically 2 to 3 axes |

| Tool Changer | Automatic tool changer with multiple tools | Tool turret with simultaneous tools |

| Common Industries | Aerospace, automotive, and electronics | Automotive, oil & gas, and heavy machinery |

| Cost | Higher due to complexity and versatility | Lower compared to machining centers |

Introduction to Machining Centers and Turning Centers

Machining centers are advanced CNC machines designed for versatile metalworking tasks including milling, drilling, and tapping with multiple axes of movement, enabling complex shaping and high precision. Turning centers, also known as CNC lathes, specialize in rotating workpieces to perform cutting, threading, and drilling operations primarily on cylindrical parts. Your choice between these centers depends on the specific manufacturing needs, such as whether you require multi-axis machining for intricate components or efficient turning for symmetrical parts.

Defining Machining Centers

Machining centers are advanced CNC machines designed for complex milling operations, offering multi-axis capabilities and tool-changing systems to enhance manufacturing efficiency and precision. These centers handle drilling, boring, and tapping in addition to milling, making them versatile for producing intricate parts. Your choice between a machining center and a turning center depends on whether your primary needs involve milling or cylindrical workpieces.

Defining Turning Centers

Turning centers are specialized CNC machines designed primarily for rotating workpieces to perform precise cutting, drilling, or threading operations on cylindrical surfaces. These centers integrate multiple axes to enable complex geometric shaping with high accuracy and efficiency, often incorporating live tooling for versatile machining processes. Your choice between a machining center and a turning center depends on whether your production emphasizes rotational parts or multi-axis milling operations.

Key Differences Between Machining Centers and Turning Centers

Machining centers use multiple cutting tools to perform milling, drilling, and tapping operations on complex parts, while turning centers primarily focus on rotary motion to shape cylindrical workpieces through cutting and facing. Machining centers typically feature a fixed worktable and rotating tool spindle, enabling versatile multi-axis machining, whereas turning centers rotate the workpiece itself against a stationary cutting tool. The key differences lie in their core functionalities: machining centers excel in multi-dimensional cutting tasks, whereas turning centers specialize in precision round component fabrication.

Applications of Machining Centers

Machining centers are primarily used for complex and high-precision manufacturing processes involving milling, drilling, and tapping operations on metal and composite materials. They excel in producing intricate parts for aerospace, automotive, and medical industries, where multi-axis capabilities enhance accuracy and efficiency. Your choice of a machining center supports versatile applications requiring detailed surface finishes and tight tolerances.

Applications of Turning Centers

Turning centers specialize in precision cylindrical part production, ideal for components such as shafts, bushings, and threaded parts. These machines excel in high-volume manufacturing of automotive, aerospace, and industrial equipment, where consistent roundness and tight tolerances are critical. Your manufacturing process benefits from turning centers' ability to perform multiple operations--like threading, grooving, and drilling--in a single setup, enhancing efficiency and reducing cycle times.

Precision and Performance Comparison

Machining centers offer superior precision in complex multi-axis milling operations, achieving tighter tolerances due to advanced CNC controls and rigid construction. Turning centers excel in high-performance cylindrical work, providing faster spindle speeds and enhanced surface finish quality for rotational parts. Performance-wise, machining centers deliver versatility for diverse milling tasks, while turning centers optimize efficiency and accuracy in lathe-based turning processes.

Cost Factors and Investment Considerations

Machining centers generally involve higher initial investment costs due to their multi-axis capabilities and advanced CNC technology, which allows for complex part fabrication in a single setup. Turning centers typically have lower purchase prices and maintenance expenses, making them cost-effective for high-volume production of cylindrical parts with consistent precision. Evaluating the cost factors requires considering the specific manufacturing needs, production volume, and potential return on investment associated with each center type.

Choosing the Right Center for Your Needs

Selecting the right center depends on the type of machining process required: machining centers excel in multi-axis milling tasks, providing precision for complex shapes and surfaces, while turning centers specialize in cylindrical workpieces with efficient rotational cutting. Consider the material, production volume, and dimensional accuracy needed, as machining centers offer greater versatility for diverse parts, whereas turning centers streamline high-volume shaft or round component manufacturing. Evaluating these factors ensures optimal investment in either a machining or turning center to maximize operational efficiency and product quality.

Future Trends in Machining and Turning Technologies

Future trends in machining centers and turning centers emphasize increased automation, integration of AI-driven predictive maintenance, and enhanced multi-axis capabilities to boost precision and efficiency. Your manufacturing processes benefit from real-time data analytics that optimize tool paths and reduce cycle times, while advanced materials and additive manufacturing integration redefine the scope of machining operations. Sustainable practices and energy-efficient technologies are also becoming standard, minimizing environmental impact alongside improved productivity.

Machining center vs turning center Infographic

libmatt.com

libmatt.com