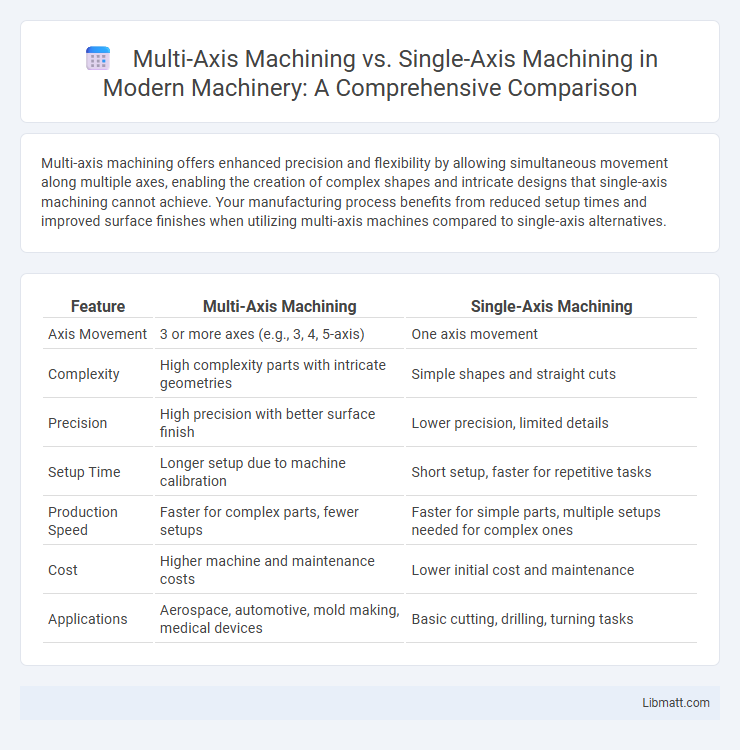

Multi-axis machining offers enhanced precision and flexibility by allowing simultaneous movement along multiple axes, enabling the creation of complex shapes and intricate designs that single-axis machining cannot achieve. Your manufacturing process benefits from reduced setup times and improved surface finishes when utilizing multi-axis machines compared to single-axis alternatives.

Table of Comparison

| Feature | Multi-Axis Machining | Single-Axis Machining |

|---|---|---|

| Axis Movement | 3 or more axes (e.g., 3, 4, 5-axis) | One axis movement |

| Complexity | High complexity parts with intricate geometries | Simple shapes and straight cuts |

| Precision | High precision with better surface finish | Lower precision, limited details |

| Setup Time | Longer setup due to machine calibration | Short setup, faster for repetitive tasks |

| Production Speed | Faster for complex parts, fewer setups | Faster for simple parts, multiple setups needed for complex ones |

| Cost | Higher machine and maintenance costs | Lower initial cost and maintenance |

| Applications | Aerospace, automotive, mold making, medical devices | Basic cutting, drilling, turning tasks |

Introduction to Multi-Axis and Single-Axis Machining

Multi-axis machining involves the movement of the tool or workpiece along multiple axes simultaneously, typically three or more, enabling complex geometries and intricate part designs. Single-axis machining operates along only one linear axis, suitable for straightforward, linear cuts and simpler components. Your choice between multi-axis and single-axis machining depends on the required precision, complexity, and production efficiency of the manufacturing project.

Defining Single-Axis Machining

Single-axis machining involves movement along a single linear axis, typically used for simple cutting tasks such as drilling or turning operations. This method offers ease of programming and lower equipment costs but lacks the ability to produce complex geometries or intricate parts. Understanding single-axis machining allows you to evaluate when simpler machining processes meet production needs versus the advanced capabilities of multi-axis systems.

Understanding Multi-Axis Machining

Multi-axis machining involves the use of multiple rotational axes, typically three to five, enabling the creation of complex geometries and intricate parts with higher precision than single-axis machining, which moves primarily along one linear axis. This advanced technique allows Your manufacturing process to improve efficiency by reducing the need for multiple setups and manual adjustments. Emphasizing CNC control systems, multi-axis machining enhances surface finish and reduces cycle times for components used in aerospace, automotive, and medical industries.

Key Differences Between Multi-Axis and Single-Axis Machining

Multi-axis machining utilizes three or more axes simultaneously, enabling complex geometries and intricate details to be produced with higher precision compared to single-axis machining, which operates typically along one axis at a time. Multi-axis machines reduce the need for multiple setups and manual repositioning by allowing continuous cutting from various angles, thereby improving efficiency and surface finish quality. Single-axis machining is more suited for simpler, linear cuts and is generally less expensive, making it ideal for basic tasks, while multi-axis machining is critical for advanced manufacturing in aerospace, automotive, and medical device industries.

Advantages of Multi-Axis Machining

Multi-axis machining offers superior precision and complex geometry capabilities compared to single-axis machining, enabling intricate cuts and detailed features in a single setup. It significantly reduces machining time and improves surface finish by allowing simultaneous movement along multiple axes. Your production efficiency increases with multi-axis machining due to minimal repositioning and higher accuracy in complex parts.

Limitations of Single-Axis Machining

Single-axis machining restricts tool movement to a single linear direction, limiting the complexity of shapes and geometric features it can produce. Its constraints make it unsuitable for intricate parts that require multiple angles or surfaces, often resulting in longer production times and increased manual finishing. You may face challenges in efficiency and precision when relying solely on single-axis machining for complex manufacturing tasks.

Applications Suited for Multi-Axis vs Single-Axis

Multi-axis machining excels in complex applications requiring intricate geometries, such as aerospace components, automotive mold making, and medical implants, where precision and surface finish are critical. Single-axis machining is best suited for simpler, repetitive tasks like drilling, turning, and basic milling operations in industries with high volume but less complex parts. Multi-axis systems enable greater flexibility and reduce setup times, making them ideal for customized and prototype manufacturing.

Precision and Complexity in Machining Operations

Multi-axis machining offers superior precision and can handle complex geometries that are challenging for single-axis machining, enabling intricate parts to be manufactured with tighter tolerances. Your projects benefit from smoother surface finishes and reduced manual adjustments due to simultaneous multi-directional tool movements. This advanced capability allows for efficient machining of components with complex contours and undercuts, enhancing overall production quality.

Cost and Efficiency Considerations

Multi-axis machining offers higher precision and faster production times compared to single-axis machining, leading to greater overall efficiency despite a higher initial investment in equipment and programming. Single-axis machining requires simpler, less expensive machinery and programming, making it more cost-effective for low-volume or less complex parts. Your choice should balance the complexity of the workpiece and production volume to optimize cost and operational efficiency.

Choosing the Right Machining Process for Your Needs

Multi-axis machining offers enhanced precision and the ability to create complex geometries compared to single-axis machining, making it ideal for intricate parts in aerospace and automotive industries. Single-axis machining is more cost-effective and efficient for simple, linear cuts and high-volume production runs. Selecting the right process depends on the complexity of the design, required tolerances, production volume, and budget constraints.

Multi-axis machining vs single-axis machining Infographic

libmatt.com

libmatt.com