VMC (Vendor Managed Inventory) optimizes supply chain efficiency by allowing suppliers to manage inventory levels directly at the customer's location, reducing stockouts and carrying costs. HMC (Hybrid Managed Care) combines traditional healthcare management with advanced technologies, improving patient outcomes and streamlining administrative processes.

Table of Comparison

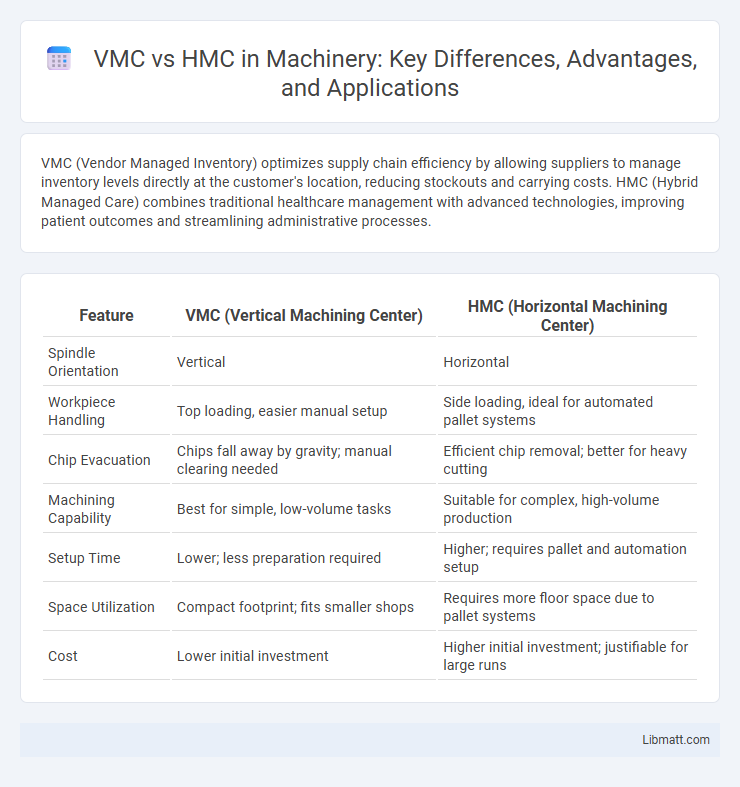

| Feature | VMC (Vertical Machining Center) | HMC (Horizontal Machining Center) |

|---|---|---|

| Spindle Orientation | Vertical | Horizontal |

| Workpiece Handling | Top loading, easier manual setup | Side loading, ideal for automated pallet systems |

| Chip Evacuation | Chips fall away by gravity; manual clearing needed | Efficient chip removal; better for heavy cutting |

| Machining Capability | Best for simple, low-volume tasks | Suitable for complex, high-volume production |

| Setup Time | Lower; less preparation required | Higher; requires pallet and automation setup |

| Space Utilization | Compact footprint; fits smaller shops | Requires more floor space due to pallet systems |

| Cost | Lower initial investment | Higher initial investment; justifiable for large runs |

Introduction to VMC and HMC

VMC (Vertical Machining Center) and HMC (Horizontal Machining Center) are advanced CNC machines designed for precision manufacturing and metalworking. VMC features a vertically oriented spindle, ideal for complex, multi-sided machining tasks with easy tool accessibility, while HMC uses a horizontal spindle, enhancing chip evacuation and enabling efficient multi-part production. Your choice between VMC and HMC depends on factors like part geometry, workflow efficiency, and production volume.

Defining Vertical Machining Centers (VMC)

Vertical Machining Centers (VMC) are CNC machines featuring a vertical spindle orientation that enables precise milling, drilling, and cutting of materials. These machines typically offer high-speed operations and superior accuracy for complex parts, making them ideal for industries requiring intricate component manufacturing. Your production efficiency can significantly improve with a VMC due to its specialization in vertical machining tasks compared to horizontal alternatives like HMC.

Understanding Horizontal Machining Centers (HMC)

Horizontal Machining Centers (HMC) feature a horizontally oriented spindle that allows for efficient chip evacuation and improved multitasking capabilities, making them ideal for complex, large-scale workpieces. Their design enhances productivity by enabling multiple operations in a single setup, reducing downtime and improving precision for your manufacturing needs. Compared to Vertical Machining Centers (VMC), HMCs offer superior access to workpieces and better tool life due to optimal chip flow and cooling.

Key Differences Between VMC and HMC

VMC (Virtual Manufacturing Control) focuses on software solutions for optimizing and managing virtual production environments, while HMC (Hybrid Manufacturing Control) integrates both physical and virtual systems to streamline manufacturing processes. VMC emphasizes simulation and digital twin technology to enhance production planning, whereas HMC combines real-time machine data with virtual models for improved decision-making and operational efficiency. Understanding these key differences helps you choose the right approach to enhance your manufacturing control strategy.

Advantages of Vertical Machining Centers

Vertical Machining Centers (VMC) offer superior ease of use and accessibility, making tool changes and workpiece setups faster compared to Horizontal Machining Centers (HMC). VMCs provide excellent visibility and precision for intricate vertical-axis operations, ideal for detailed part manufacturing and quick prototyping. Their compact footprint often reduces factory floor space requirements while delivering efficient material removal rates for a wide range of industries.

Benefits of Horizontal Machining Centers

Horizontal Machining Centers (HMC) offer enhanced chip evacuation due to their spindle orientation, improving cutting efficiency and tool life compared to Vertical Machining Centers (VMC). HMCs provide superior multi-sided machining capabilities, reducing the need for multiple setups and increasing overall productivity. Their robust construction allows for heavy-duty milling and greater precision in complex parts manufacturing.

Application Suitability: VMC vs HMC

VMC (Vertical Machining Centers) are ideal for precision milling, drilling, and boring in industries such as aerospace, automotive, and metal fabrication, offering excellent accessibility for complex part geometries. HMC (Horizontal Machining Centers) excel in high-volume production environments, particularly in automotive and heavy equipment manufacturing, due to their superior chip evacuation and ability to machine large workpieces with multiple sides in a single setup. Choosing between VMC and HMC depends on factors like production volume, part complexity, and workspace layout, with VMCs favored for versatility and HMCs optimized for efficiency in mass production.

Cost Comparison: VMC and HMC

VMC (VMware Cloud) generally incurs higher costs due to its integrated cloud services, licensing fees, and premium support, whereas HMC (Hardware Management Console) involves a one-time hardware expense with lower ongoing operational costs. Your total cost of ownership for VMC includes subscription fees tied to cloud usage, while HMC's expenses center around hardware maintenance and firmware updates. Evaluating workload requirements and scalability needs helps determine which option provides better cost efficiency for your environment.

Factors to Consider When Choosing VMC or HMC

When choosing between Vertical Machining Centers (VMC) and Horizontal Machining Centers (HMC), factors such as workpiece size, complexity, and production volume must be considered. VMCs typically excel in handling smaller, simpler parts with easier setup and accessibility, while HMCs offer superior efficiency for large, complex components and higher-volume manufacturing due to better chip evacuation and multi-sided machining capabilities. Your specific manufacturing needs and floor space constraints will ultimately determine the optimal choice for productivity and cost-effectiveness.

Conclusion: Selecting the Right Machining Center

When selecting the right machining center, consider that VMCs (Vertical Machining Centers) are ideal for precision tasks and easier tool access, while HMCs (Horizontal Machining Centers) offer superior chip evacuation and multi-sided machining capabilities. Your production volume, part complexity, and workflow requirements will determine which machine maximizes efficiency and throughput. Choosing the appropriate center enhances machining accuracy and operational productivity.

VMC vs HMC Infographic

libmatt.com

libmatt.com