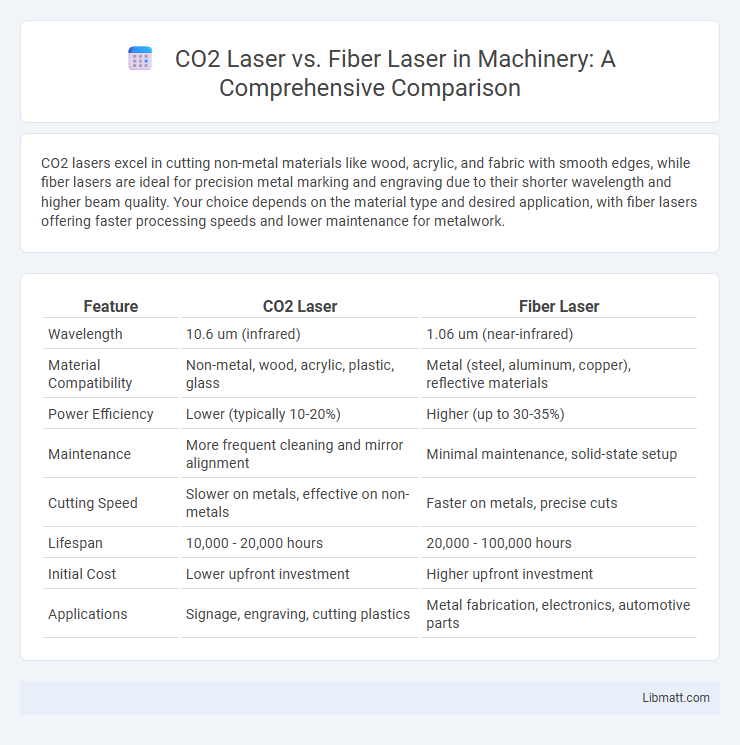

CO2 lasers excel in cutting non-metal materials like wood, acrylic, and fabric with smooth edges, while fiber lasers are ideal for precision metal marking and engraving due to their shorter wavelength and higher beam quality. Your choice depends on the material type and desired application, with fiber lasers offering faster processing speeds and lower maintenance for metalwork.

Table of Comparison

| Feature | CO2 Laser | Fiber Laser |

|---|---|---|

| Wavelength | 10.6 um (infrared) | 1.06 um (near-infrared) |

| Material Compatibility | Non-metal, wood, acrylic, plastic, glass | Metal (steel, aluminum, copper), reflective materials |

| Power Efficiency | Lower (typically 10-20%) | Higher (up to 30-35%) |

| Maintenance | More frequent cleaning and mirror alignment | Minimal maintenance, solid-state setup |

| Cutting Speed | Slower on metals, effective on non-metals | Faster on metals, precise cuts |

| Lifespan | 10,000 - 20,000 hours | 20,000 - 100,000 hours |

| Initial Cost | Lower upfront investment | Higher upfront investment |

| Applications | Signage, engraving, cutting plastics | Metal fabrication, electronics, automotive parts |

Introduction to CO2 and Fiber Lasers

CO2 lasers use a gas mixture primarily composed of carbon dioxide, nitrogen, and helium to generate infrared light at a wavelength of 10.6 micrometers, making them ideal for cutting, engraving, and marking non-metal materials like wood, acrylic, and glass. Fiber lasers operate by amplifying light through a doped optical fiber, emitting wavelengths around 1.06 micrometers, which allows for high precision and efficiency in metal processing such as steel, aluminum, and copper. Your choice between CO2 and fiber lasers depends on the material type, application requirements, and desired cutting speed.

How CO2 Lasers Work

CO2 lasers operate by electrically stimulating a gas mixture containing carbon dioxide, nitrogen, and helium to produce a high-powered infrared beam ideal for cutting, engraving, and marking non-metal materials like wood, acrylic, and glass. The laser generates light at a wavelength of 10.6 micrometers, which is absorbed effectively by organic materials, enabling precise and clean cuts. Understanding how your CO2 laser works can help optimize settings for material-specific applications and improve overall efficiency in production processes.

How Fiber Lasers Work

Fiber lasers generate laser beams by pumping light through optical fibers doped with rare-earth elements such as erbium or ytterbium, creating a highly efficient and stable light source. The laser beam is delivered through flexible, durable optical fibers, allowing precise cutting and engraving with minimal maintenance. Compared to CO2 lasers, fiber lasers offer faster processing speeds and better energy efficiency, especially on metal materials.

Key Differences Between CO2 and Fiber Lasers

CO2 lasers use a gas mixture, primarily carbon dioxide, to generate infrared light at a wavelength of approximately 10.6 microns, making them ideal for cutting non-metal materials like wood, acrylic, and glass. Fiber lasers emit light through a solid-state fiber doped with rare-earth elements, typically operating at a shorter wavelength around 1.06 microns, which provides superior efficiency and precision for metal cutting and marking applications. Key differences include the laser medium, wavelength, material compatibility, cutting speed, and maintenance requirements, with fiber lasers generally offering lower operational costs and higher beam quality for metals.

Material Compatibility: CO2 vs Fiber Lasers

CO2 lasers excel at cutting and engraving non-metal materials such as wood, acrylic, glass, and leather due to their longer 10.6-micron wavelength, which is highly absorbed by organic and non-metal surfaces. Fiber lasers operate at a shorter wavelength around 1.06 microns, making them ideal for processing metals like stainless steel, aluminum, and copper with high precision and speed. Material compatibility drives the choice between CO2 and fiber lasers, with CO2 preferred for non-metals and fiber lasers dominating in metal applications.

Cutting Speed and Efficiency Comparison

Fiber lasers offer significantly faster cutting speeds than CO2 lasers, particularly when processing thin metals such as stainless steel and aluminum, due to their higher beam quality and energy absorption efficiency. The higher electrical-to-optical efficiency of fiber lasers reduces operating costs and energy consumption, making them more cost-effective for high-volume production. CO2 lasers, while slower, still provide exceptional performance on thicker non-metal materials, but overall fiber lasers are preferred for rapid, precise metal cutting applications.

Precision and Edge Quality Differences

CO2 lasers typically offer superior edge quality for cutting thicker, non-metal materials due to their longer wavelength, which results in cleaner, smoother edges with less kerf. Fiber lasers provide higher precision and edge quality on thin metals, achieving minimal heat-affected zones and fine, sharp cut edges because of their shorter wavelength and higher beam quality. The choice between CO2 and fiber laser depends on material type and thickness, with fiber lasers excelling in metal precision and CO2 lasers preferred for clean edges on organic materials.

Maintenance and Operating Costs

CO2 lasers generally require more frequent maintenance due to their gas-based components, leading to higher operating costs over time compared to fiber lasers. Fiber lasers offer longer lifespans and reduced downtime with minimal maintenance, resulting in lower overall operational expenses. Your choice between the two should consider these cost implications along with specific application needs to maximize efficiency and reduce expenditure.

Typical Applications of CO2 and Fiber Lasers

CO2 lasers excel in cutting and engraving non-metal materials such as wood, acrylic, leather, and glass, making them ideal for signage, textile, and packaging industries. Fiber lasers, known for their superior precision and efficiency on metals like stainless steel, aluminum, and copper, are commonly used in electronics manufacturing, automotive parts production, and medical device fabrication. Your choice between CO2 and fiber lasers depends on the material type and application requirements for optimal performance.

Choosing the Right Laser for Your Needs

Choosing the right laser for your needs depends on the material and application; CO2 lasers excel at cutting and engraving non-metal materials like wood, acrylic, and glass due to their longer wavelength around 10.6 microns. Fiber lasers operate at shorter wavelengths near 1.06 microns, offering higher precision and efficiency for metals and reflective materials such as stainless steel and aluminum. Understanding these differences ensures your investment delivers optimal performance, whether for industrial cutting, marking, or engraving tasks.

CO2 laser vs fiber laser Infographic

libmatt.com

libmatt.com