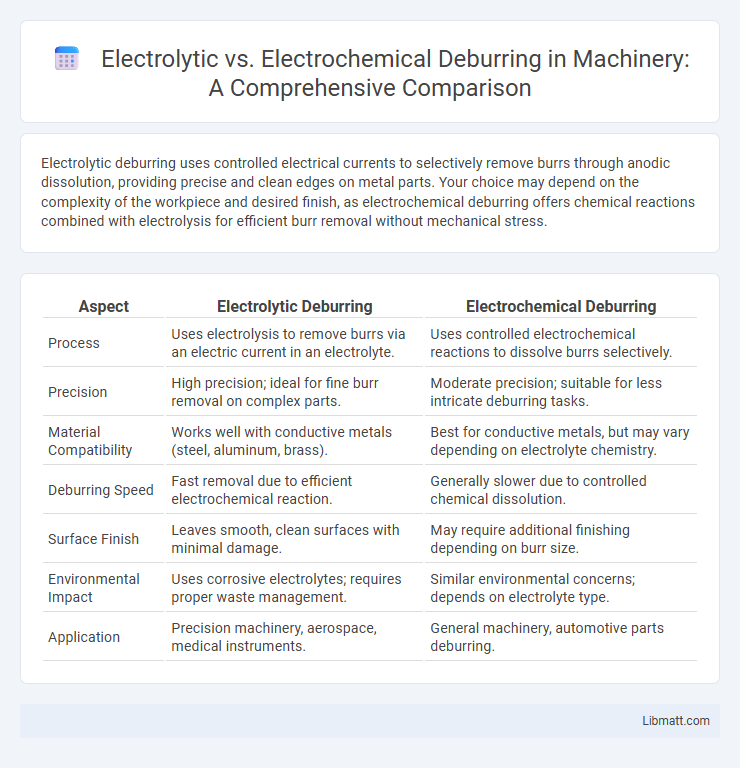

Electrolytic deburring uses controlled electrical currents to selectively remove burrs through anodic dissolution, providing precise and clean edges on metal parts. Your choice may depend on the complexity of the workpiece and desired finish, as electrochemical deburring offers chemical reactions combined with electrolysis for efficient burr removal without mechanical stress.

Table of Comparison

| Aspect | Electrolytic Deburring | Electrochemical Deburring |

|---|---|---|

| Process | Uses electrolysis to remove burrs via an electric current in an electrolyte. | Uses controlled electrochemical reactions to dissolve burrs selectively. |

| Precision | High precision; ideal for fine burr removal on complex parts. | Moderate precision; suitable for less intricate deburring tasks. |

| Material Compatibility | Works well with conductive metals (steel, aluminum, brass). | Best for conductive metals, but may vary depending on electrolyte chemistry. |

| Deburring Speed | Fast removal due to efficient electrochemical reaction. | Generally slower due to controlled chemical dissolution. |

| Surface Finish | Leaves smooth, clean surfaces with minimal damage. | May require additional finishing depending on burr size. |

| Environmental Impact | Uses corrosive electrolytes; requires proper waste management. | Similar environmental concerns; depends on electrolyte type. |

| Application | Precision machinery, aerospace, medical instruments. | General machinery, automotive parts deburring. |

Introduction to Deburring Technologies

Electrolytic deburring uses an electrical current and electrolyte solution to dissolve burrs precisely from metal surfaces, ideal for intricate parts with tight tolerances. Electrochemical deburring, a broader process, also employs electrochemical reactions but can include techniques like electrochemical machining for material removal beyond just burr elimination. Understanding these technologies helps select the best method to enhance your components' finish and functionality.

Overview of Electrolytic Deburring

Electrolytic deburring is a precise metal finishing process that removes burrs by using controlled electrochemical dissolution, ensuring minimal damage to the workpiece surface. This technique involves an electrolytic cell where electrical current flows between the workpiece and a specially designed cathode, selectively eroding burrs while preserving fine details. Your components benefit from reduced mechanical stress and enhanced surface smoothness, making this method ideal for intricate and delicate parts.

Understanding Electrochemical Deburring

Electrochemical deburring utilizes anodic dissolution to precisely remove burrs by applying an electric current in an electrolyte solution, targeting microscopic metal protrusions without mechanical contact. This process ensures high accuracy and prevents workpiece distortion, making it ideal for complex geometries and delicate components. Unlike traditional abrasive methods, electrochemical deburring operates efficiently on hard-to-reach areas and maintains surface integrity by minimizing thermal or mechanical stress.

Electrolytic Deburring: Process and Applications

Electrolytic deburring is a precise metal finishing process that removes burrs and sharp edges from conductive materials through controlled anodic dissolution using an electrolytic solution and electric current. This method excels in deburring complex geometries and hard-to-reach areas, commonly applied in aerospace, medical device manufacturing, and precision engineering industries. The process offers high accuracy, minimal mechanical stress, and improved surface finish, making it ideal for delicate components requiring consistent burr removal.

Electrochemical Deburring: Process and Applications

Electrochemical deburring (ECD) harnesses controlled anodic dissolution to precisely remove burrs and sharp edges from complex metal parts, enhancing surface finish without mechanical stress. Commonly applied in aerospace, medical device manufacturing, and micro-machining industries, ECD efficiently deburrs hard-to-reach internal geometries and delicate components. The process involves an electrolyte solution, a cathode tool, and electric current to selectively dissolve unwanted material, ensuring consistent precision and minimal thermal or mechanical distortion.

Key Differences Between Electrolytic and Electrochemical Deburring

Electrolytic deburring uses direct current to remove burrs by anodic dissolution in a highly controlled manner, targeting sharp edges with precision. Electrochemical deburring operates similarly but emphasizes broader anodic material removal, often suitable for complex shapes and delicate components. Your choice depends on the required accuracy and the complexity of the workpiece geometry in the deburring process.

Advantages and Limitations: Electrolytic Deburring

Electrolytic deburring offers high precision in removing burrs from intricate and hard-to-reach areas, resulting in smooth edges without mechanical stress on the workpiece. Its advantages include fast processing times and the ability to debur multiple parts simultaneously, improving production efficiency. However, limitations involve higher operational costs due to electrolyte maintenance and disposal, as well as potential environmental concerns and the necessity for precise control to avoid excessive material removal.

Pros and Cons: Electrochemical Deburring

Electrochemical deburring offers precise removal of burrs with minimal thermal and mechanical stress on your parts, making it ideal for delicate or complex geometries. The process produces smooth finishes and does not wear down tool components, but it requires careful handling of chemicals and generates waste that must be managed responsibly. While highly efficient for batch processing, reliance on electrolyte solutions and setup costs can be disadvantages compared to other deburring methods.

Industrial Use Cases and Suitability

Electrolytic deburring excels in industrial applications requiring precise removal of burrs from complex, miniature components such as aerospace turbine blades and intricate medical devices, offering high accuracy and minimal thermal impact. Electrochemical deburring is suitable for large-scale manufacturing environments handling harder materials like stainless steel or titanium, where efficient burr removal and minimal mechanical stress are critical. The choice depends on component geometry, material composition, and production volume, ensuring optimal surface finish and operational efficiency.

Choosing the Right Deburring Method

Electrolytic deburring uses controlled electric current and electrolyte to selectively dissolve burrs on metal surfaces, ideal for precise edge finishing on complex parts. Electrochemical deburring operates similarly but excels in removing burrs from intricate geometries and hard-to-reach internal features by adjusting current density and electrolyte flow. Understanding the material type, burr location, and precision requirements helps you choose the most effective deburring method for optimal surface quality and production efficiency.

Electrolytic vs electrochemical deburring Infographic

libmatt.com

libmatt.com