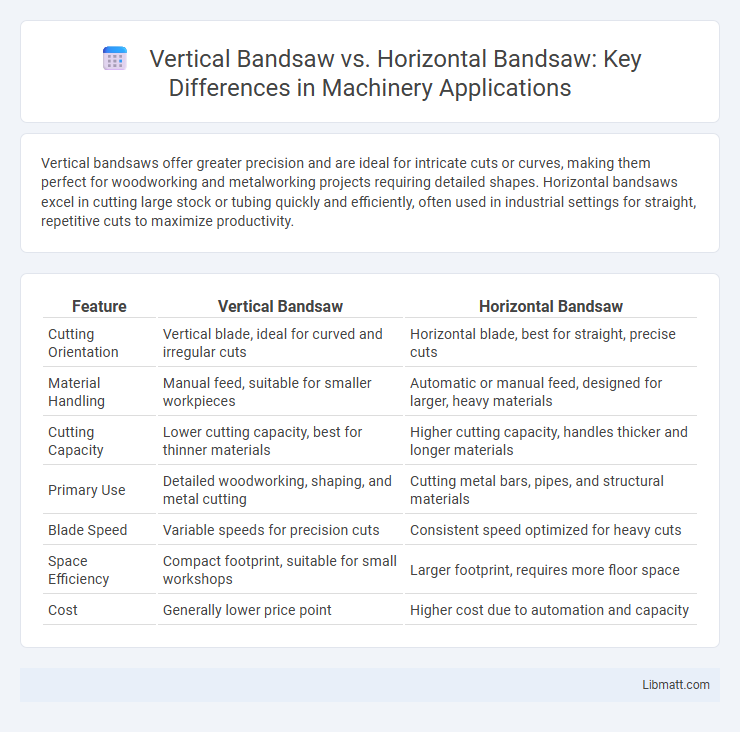

Vertical bandsaws offer greater precision and are ideal for intricate cuts or curves, making them perfect for woodworking and metalworking projects requiring detailed shapes. Horizontal bandsaws excel in cutting large stock or tubing quickly and efficiently, often used in industrial settings for straight, repetitive cuts to maximize productivity.

Table of Comparison

| Feature | Vertical Bandsaw | Horizontal Bandsaw |

|---|---|---|

| Cutting Orientation | Vertical blade, ideal for curved and irregular cuts | Horizontal blade, best for straight, precise cuts |

| Material Handling | Manual feed, suitable for smaller workpieces | Automatic or manual feed, designed for larger, heavy materials |

| Cutting Capacity | Lower cutting capacity, best for thinner materials | Higher cutting capacity, handles thicker and longer materials |

| Primary Use | Detailed woodworking, shaping, and metal cutting | Cutting metal bars, pipes, and structural materials |

| Blade Speed | Variable speeds for precision cuts | Consistent speed optimized for heavy cuts |

| Space Efficiency | Compact footprint, suitable for small workshops | Larger footprint, requires more floor space |

| Cost | Generally lower price point | Higher cost due to automation and capacity |

Introduction to Vertical and Horizontal Bandsaws

Vertical bandsaws feature a blade that moves vertically, offering precision cutting for curved and irregular shapes, making them ideal for intricate woodworking or metalworking projects. Horizontal bandsaws have a blade that moves horizontally, designed primarily for straight cuts and metal fabrication, providing efficient, consistent cuts on larger materials. Your choice depends on the specific cutting needs and material types required for your workshop tasks.

Key Differences Between Vertical and Horizontal Bandsaws

Vertical bandsaws feature a blade that cuts downward, ideal for intricate curves and detailed cuts in wood, metal, or plastic, while horizontal bandsaws use a blade positioned horizontally, designed mainly for straight, precise cuts in larger workpieces like pipes or metal bars. The vertical saw offers greater control and versatility for shaping and resawing tasks, whereas the horizontal model excels in cutting stock material to length with consistent accuracy and efficiency. Your choice depends on whether precision curve cutting or repetitive straight cuts in heavy materials are the priority for your workshop.

Design and Structure Comparison

Vertical bandsaws feature a blade oriented vertically, allowing precise, intricate cuts ideal for curves and irregular shapes, while horizontal bandsaws have a horizontally mounted blade designed for making straight, uniform cuts, especially in metal fabrication. The vertical design often incorporates a stationary worktable and adjustable blade guides, enhancing control for detailed work, whereas horizontal designs typically include a movable vice or clamp to secure the material during cutting. Structural differences influence their applications: vertical bandsaws excel in woodworking and fine metal cutting, while horizontal bandsaws are preferred for heavy-duty, repetitive straight cuts in industrial environments.

Cutting Capabilities and Applications

Vertical bandsaws excel in intricate, curved, or irregular cuts, making them ideal for metal fabrication, woodworking, and detailed shaping tasks. Horizontal bandsaws offer superior capabilities for straight, precise cuts in large, heavy materials such as pipes, bars, and structural steel, commonly used in industrial manufacturing and construction. Your choice depends on whether you prioritize versatility in shaping or efficiency in cutting large stock.

Space and Footprint Considerations

Vertical bandsaws have a smaller footprint compared to horizontal bandsaws, making them ideal for workshops with limited floor space. Horizontal bandsaws typically require more room due to their larger size and the need to accommodate longer material feed lengths. Your choice depends on available space and the type of work, with vertical models being more compact and horizontal models suited for high-volume, long-cut applications.

Material Versatility and Thickness Handling

Vertical bandsaws excel in cutting a wide variety of materials, including intricate shapes in metals, plastics, and wood, making them ideal for detailed work and thicknesses up to several inches. Horizontal bandsaws offer superior performance for handling thicker materials and straight cuts, commonly used in metal fabrication and heavy-duty applications where consistent cross-sectional cuts are required. Your choice between vertical and horizontal bandsaws should depend on the specific material types and thickness ranges you need to work with for optimal versatility and precision.

Precision, Control, and Finish Quality

Vertical bandsaws offer superior precision and finer control due to their ergonomic design, allowing detailed cuts and intricate shapes with minimal material waste. Horizontal bandsaws excel in delivering consistent, straight cuts ideal for large or repetitive tasks, ensuring a smooth finish on thicker materials. Finish quality on vertical bandsaws typically benefits from slower cutting speeds and adjustable guides, while horizontal bandsaws prioritize power and durability for rougher, high-volume cutting operations.

Safety Features and Ergonomics

Vertical bandsaws typically offer enhanced safety features such as blade guards and adjustable blade guides that reduce the risk of accidental contact, while their ergonomic design allows operators to work in a comfortable standing position. Horizontal bandsaws, on the other hand, prioritize stability and ease of handling larger materials but may require additional safety measures like secure clamping systems to prevent movement during cutting. Your choice between the two should consider the balance of safety safeguards and ergonomic comfort based on the specific demands of your workflow.

Maintenance Requirements and Durability

Vertical bandsaws typically require more frequent blade tension adjustments and guide replacements due to their upright position, which subjects blades to greater gravitational stress. Horizontal bandsaws offer enhanced durability with robust frame construction that minimizes vibration and blade wear, making them ideal for heavy-duty, continuous use. Your choice should consider maintenance accessibility and long-term durability based on the specific workload and material cutting demands.

Choosing the Right Bandsaw for Your Workshop

When choosing the right bandsaw for your workshop, consider the cutting direction and material type: vertical bandsaws provide superior precision and versatility for intricate curves and irregular shapes, ideal for woodworking and metal shaping tasks. Horizontal bandsaws excel in making straight, repetitive cuts on larger metal stock, offering higher stability and efficiency for industrial or heavy-duty metal cutting. Evaluating your primary cutting needs and workspace constraints ensures optimal performance and productivity from your bandsaw choice.

Vertical bandsaw vs horizontal bandsaw Infographic

libmatt.com

libmatt.com