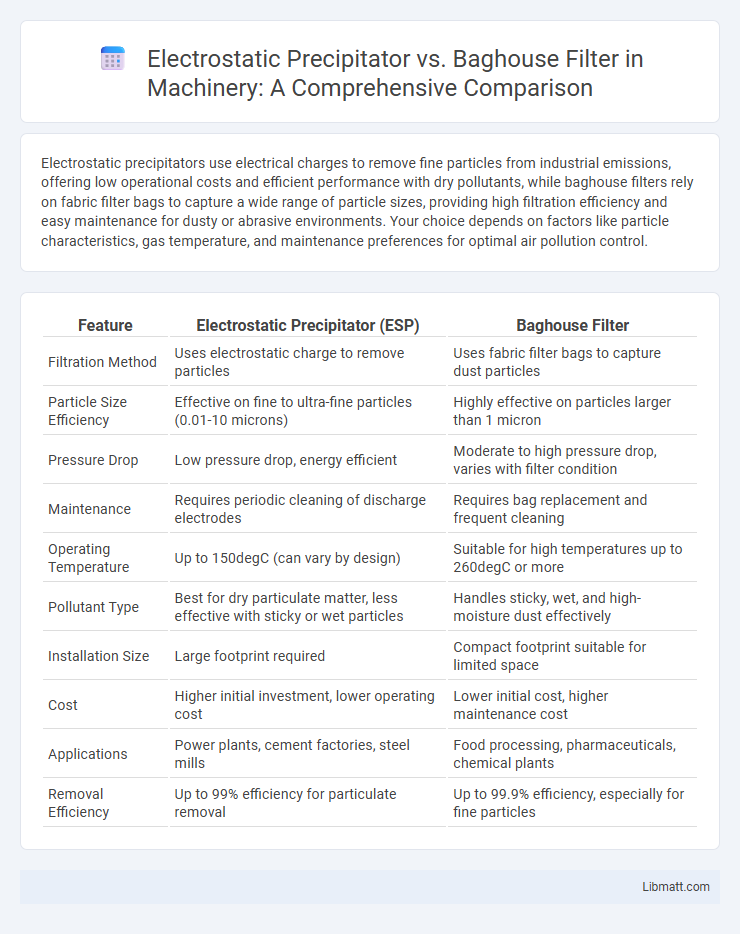

Electrostatic precipitators use electrical charges to remove fine particles from industrial emissions, offering low operational costs and efficient performance with dry pollutants, while baghouse filters rely on fabric filter bags to capture a wide range of particle sizes, providing high filtration efficiency and easy maintenance for dusty or abrasive environments. Your choice depends on factors like particle characteristics, gas temperature, and maintenance preferences for optimal air pollution control.

Table of Comparison

| Feature | Electrostatic Precipitator (ESP) | Baghouse Filter |

|---|---|---|

| Filtration Method | Uses electrostatic charge to remove particles | Uses fabric filter bags to capture dust particles |

| Particle Size Efficiency | Effective on fine to ultra-fine particles (0.01-10 microns) | Highly effective on particles larger than 1 micron |

| Pressure Drop | Low pressure drop, energy efficient | Moderate to high pressure drop, varies with filter condition |

| Maintenance | Requires periodic cleaning of discharge electrodes | Requires bag replacement and frequent cleaning |

| Operating Temperature | Up to 150degC (can vary by design) | Suitable for high temperatures up to 260degC or more |

| Pollutant Type | Best for dry particulate matter, less effective with sticky or wet particles | Handles sticky, wet, and high-moisture dust effectively |

| Installation Size | Large footprint required | Compact footprint suitable for limited space |

| Cost | Higher initial investment, lower operating cost | Lower initial cost, higher maintenance cost |

| Applications | Power plants, cement factories, steel mills | Food processing, pharmaceuticals, chemical plants |

| Removal Efficiency | Up to 99% efficiency for particulate removal | Up to 99.9% efficiency, especially for fine particles |

Introduction to Electrostatic Precipitators and Baghouse Filters

Electrostatic precipitators use high-voltage electrical charges to remove particulate matter from industrial gases, making them highly effective for capturing fine particles. Baghouse filters rely on fabric filter bags that trap dust and other particulates as gases pass through, offering versatile filtration for various particle sizes. Your choice between these technologies depends on factors like particle size, gas composition, and operational costs.

How Electrostatic Precipitators Work

Electrostatic precipitators (ESPs) remove particles from industrial emissions by charging particles electrically and collecting them on charged plates. This process effectively captures fine particulate matter, such as dust and smoke, improving air quality. Your facility can benefit from ESPs' high efficiency in handling large gas volumes with low pressure drop.

How Baghouse Filters Operate

Baghouse filters operate by forcing polluted air through fabric filter bags that trap particulate matter on their surface, allowing clean air to pass through. The collected dust accumulates on the bag exterior and is periodically removed by shaking or pulse-jet cleaning, ensuring continuous filtration efficiency. Your industrial processes benefit from baghouse filters' ability to capture fine particles and handle high dust loads effectively.

Efficiency Comparison: Electrostatic Precipitator vs Baghouse Filter

Electrostatic precipitators (ESPs) achieve particle removal efficiencies of up to 99% for fine particulate matter, making them highly effective for large-scale industrial applications. Baghouse filters typically provide particulate collection efficiencies exceeding 99.9%, especially for smaller dust particles, due to their fabric filtration mechanism. Your choice between ESP and baghouse filter depends on the specific particulate size distribution, operational costs, and maintenance requirements required for optimal air pollution control.

Particle Size and Collection Capabilities

Electrostatic precipitators excel at capturing fine particles as small as 0.01 microns through electrical charging mechanisms, making them highly effective for ultrafine particulate collection. Baghouse filters, using fabric filter bags, provide superior efficiency in trapping larger particles above 1 micron, often achieving collection efficiencies exceeding 99.9% for dust and particulate matter. Your choice between these technologies should consider the specific particle size distribution and collection performance required for optimal air pollution control.

Maintenance Requirements and Operational Costs

Electrostatic precipitators require regular cleaning of collection plates and periodic inspection of high-voltage components, resulting in moderate maintenance demands and associated costs. Baghouse filters need frequent replacement of filter bags and routine checks for bag integrity, which often leads to higher ongoing maintenance expenses. Your choice between the two should consider these operational costs relative to the specific particulate control needs and maintenance capabilities of your facility.

Applications in Industry: Choosing the Right System

Electrostatic precipitators excel in removing fine particles and are widely used in power plants and cement industries for controlling dust emissions from flue gases. Baghouse filters are preferred for industries handling large volumes of coarse dust, such as woodworking and metal fabrication, due to their high filtration efficiency and ease of maintenance. Your choice between these systems should consider the particle size, temperature, and gas composition to ensure optimal air pollution control and compliance with environmental regulations.

Environmental Impact and Emissions Control

Electrostatic precipitators (ESPs) efficiently remove fine particulate matter by using electrical charges, capturing up to 99% of particles, which significantly reduces air pollution and helps meet stringent environmental regulations. Baghouse filters excel in capturing a broader range of particle sizes, including very fine dust, ensuring enhanced emissions control and lower particulate emissions compared to ESPs in some applications. Both technologies contribute to minimizing environmental impact by preventing harmful particulate emissions from industrial processes, but baghouse filters generally provide superior performance for ultra-fine particulate matter control and are preferred in industries with strict air quality standards.

Advantages and Disadvantages of Each Technology

Electrostatic precipitators (ESPs) offer high efficiency in removing fine particulate matter and operate with low pressure drop, but they require significant initial investment and are less effective with high-resistivity dust or variable flue gas compositions. Baghouse filters excel in capturing a wide range of particle sizes with consistently high filtration efficiency and adaptability to changing gas compositions, yet they involve higher maintenance costs and increased energy consumption due to their higher pressure drop. Choosing between ESPs and baghouse filters depends on specific industrial applications, particulate characteristics, and operational priorities such as cost, maintenance, and emission regulations.

Future Trends in Particulate Removal Technologies

Future trends in particulate removal technologies emphasize enhanced efficiency and sustainability, with electrostatic precipitators (ESPs) integrating advanced power supplies and real-time monitoring systems to optimize particle capture. Baghouse filters are evolving through the use of high-performance, nanofiber media that increase filtration accuracy and durability while reducing energy consumption. Both technologies are increasingly adopting IoT connectivity and AI-driven controls to improve predictive maintenance and reduce downtime in industrial applications.

Electrostatic precipitator vs baghouse filter Infographic

libmatt.com

libmatt.com