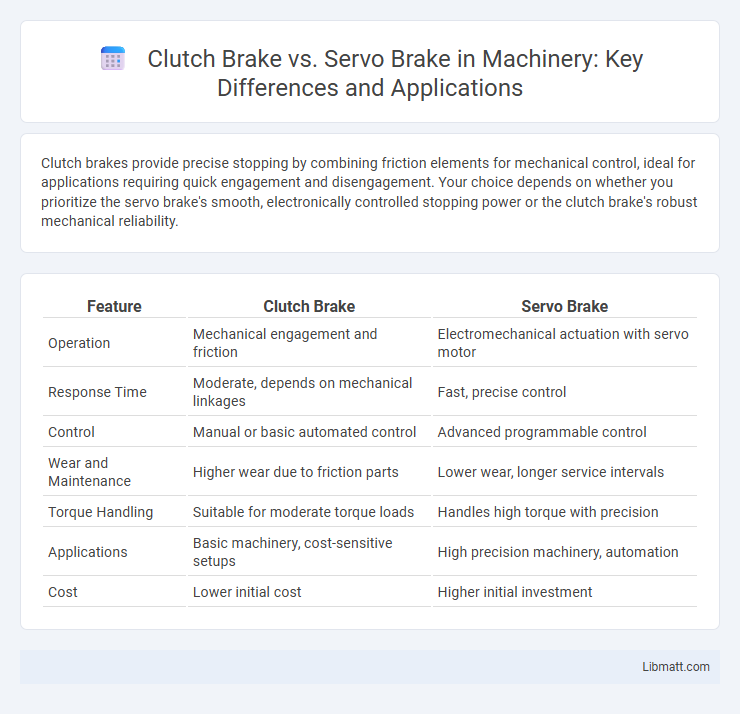

Clutch brakes provide precise stopping by combining friction elements for mechanical control, ideal for applications requiring quick engagement and disengagement. Your choice depends on whether you prioritize the servo brake's smooth, electronically controlled stopping power or the clutch brake's robust mechanical reliability.

Table of Comparison

| Feature | Clutch Brake | Servo Brake |

|---|---|---|

| Operation | Mechanical engagement and friction | Electromechanical actuation with servo motor |

| Response Time | Moderate, depends on mechanical linkages | Fast, precise control |

| Control | Manual or basic automated control | Advanced programmable control |

| Wear and Maintenance | Higher wear due to friction parts | Lower wear, longer service intervals |

| Torque Handling | Suitable for moderate torque loads | Handles high torque with precision |

| Applications | Basic machinery, cost-sensitive setups | High precision machinery, automation |

| Cost | Lower initial cost | Higher initial investment |

Introduction to Clutch Brake and Servo Brake

Clutch brakes and servo brakes are essential components in industrial machinery used to control motion and enhance operational efficiency. A clutch brake integrates a clutch mechanism with a braking system, enabling smooth engagement and rapid stopping of rotating parts, commonly found in presses and packaging equipment. Servo brakes utilize advanced servo motors combined with braking units to provide precise and programmable control of torque and speed, ideal for applications requiring high accuracy and dynamic response.

How Clutch Brakes Work

Clutch brakes operate by combining the functions of a clutch and a brake within a single unit to control rotational motion and stop machinery quickly and precisely. The clutch engages or disengages power transmission between the driving and driven components, while the brake applies friction to halt the rotation immediately once the clutch disengages. Understanding how clutch brakes work helps you optimize machine safety and improve operational efficiency in industrial applications.

Understanding Servo Brakes

Servo brakes use the input torque to amplify braking force, providing higher efficiency and faster response times compared to clutch brakes. These brakes are commonly found in industrial machinery where precise control and reliable stopping power are critical. Understanding servo brakes involves recognizing their self-energizing mechanism, which reduces energy consumption and enhances performance during high-load operations.

Key Differences Between Clutch Brake and Servo Brake

Clutch brakes engage through friction plates that mechanically connect or disconnect power transmission, while servo brakes utilize electromagnetic or hydraulic force to amplify braking power with greater precision. Clutch brakes are generally simpler and more cost-effective for low to medium torque applications, whereas servo brakes provide faster response times and better control in high-torque, dynamic environments. Your selection depends on factors like required braking force, system complexity, and response speed.

Performance Comparison: Speed and Precision

Clutch brakes offer rapid engagement and disengagement, making them suitable for applications requiring quick start-stop cycles with moderate precision. Servo brakes provide superior speed control and high precision due to their electronically controlled actuation, ensuring smooth and accurate stopping in complex machinery. Your choice between the two depends on the balance between speed responsiveness and the level of braking accuracy needed for your specific operation.

Energy Efficiency: Clutch Brake vs Servo Brake

Servo brakes offer superior energy efficiency compared to clutch brakes by utilizing electrical input that only consumes power during activation and requires minimal energy to maintain holding torque. Clutch brakes rely on continuous mechanical engagement and friction, resulting in higher energy loss and heat generation during operation. The precise control and lower power consumption of servo brakes make them ideal for applications demanding reduced energy usage and enhanced system longevity.

Maintenance and Longevity

Clutch brakes typically require more frequent maintenance due to wear on friction materials and the need for regular adjustment to ensure proper engagement, impacting their overall longevity. Servo brakes, with their hydraulic or pneumatic actuation, offer more consistent braking force and generally experience less wear, resulting in extended service life and lower maintenance demands. Choosing a servo brake can enhance your system's reliability and reduce downtime over time.

Application Suitability in Various Industries

Clutch brakes are ideal for applications requiring precise start-stop control and are prevalent in packaging, printing, and textile industries where rapid cycling and load control are critical. Servo brakes offer superior torque modulation and energy efficiency, making them well-suited for heavy-duty manufacturing, robotics, and automation sectors demanding high precision and reliability. Your choice between these braking systems should align with the specific operational demands and load characteristics of your industry to ensure optimal performance and equipment longevity.

Cost Analysis: Initial Investment and Operation

Clutch brakes generally require a lower initial investment compared to servo brakes, making them cost-effective for small to medium-sized applications. Servo brakes demand higher upfront costs due to complex components and advanced control systems but offer improved efficiency and reduced operational expenses over time. You should evaluate your budget and long-term operational needs to determine the best balance between immediate costs and ongoing savings.

Choosing the Right Brake System for Your Needs

Selecting between a clutch brake and a servo brake depends on the application's precision and torque requirements. Clutch brakes offer cost-effective, quick engagement suitable for simpler machines, while servo brakes provide higher torque capacity and smoother, electronically controlled operation ideal for complex or high-load systems. Evaluate factors such as load dynamics, control accuracy, and maintenance demands to ensure optimal performance and longevity.

Clutch brake vs servo brake Infographic

libmatt.com

libmatt.com