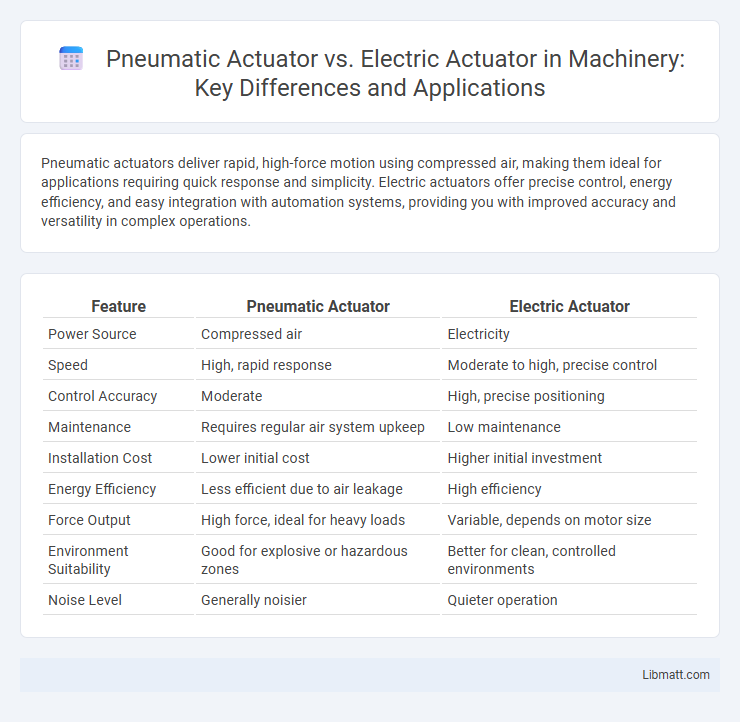

Pneumatic actuators deliver rapid, high-force motion using compressed air, making them ideal for applications requiring quick response and simplicity. Electric actuators offer precise control, energy efficiency, and easy integration with automation systems, providing you with improved accuracy and versatility in complex operations.

Table of Comparison

| Feature | Pneumatic Actuator | Electric Actuator |

|---|---|---|

| Power Source | Compressed air | Electricity |

| Speed | High, rapid response | Moderate to high, precise control |

| Control Accuracy | Moderate | High, precise positioning |

| Maintenance | Requires regular air system upkeep | Low maintenance |

| Installation Cost | Lower initial cost | Higher initial investment |

| Energy Efficiency | Less efficient due to air leakage | High efficiency |

| Force Output | High force, ideal for heavy loads | Variable, depends on motor size |

| Environment Suitability | Good for explosive or hazardous zones | Better for clean, controlled environments |

| Noise Level | Generally noisier | Quieter operation |

Introduction to Pneumatic and Electric Actuators

Pneumatic actuators use compressed air to generate mechanical motion, offering fast response times and high force output ideal for industrial automation. Electric actuators rely on electric motors to produce precise and controllable motion, making them suitable for applications requiring accuracy and energy efficiency. Both actuator types serve critical roles in controlling valves and machinery, with selection depending on factors like operating environment, load requirements, and control precision.

Working Principles of Pneumatic Actuators

Pneumatic actuators operate by converting compressed air pressure into mechanical motion, typically through the movement of a piston or diaphragm within a cylinder. This air-driven mechanism allows precise control of valve positioning and quick response times, making pneumatic actuators ideal for industrial automation and control systems. The simplicity and reliability of pneumatic actuators stem from their fewer moving parts and resistance to harsh environments compared to electric actuators.

Working Principles of Electric Actuators

Electric actuators operate by converting electrical energy into mechanical motion through a motor, typically using gears or screws to control valve positioning with precision. These actuators deliver consistent torque and speed, enabling smooth and accurate control in automated systems. Your choice of an electric actuator ensures reliable performance in applications requiring precise adjustments and low maintenance.

Key Differences Between Pneumatic and Electric Actuators

Pneumatic actuators use compressed air to create motion, offering fast response and high force output, ideal for harsh environments and explosive atmospheres. Electric actuators provide precise control, energy efficiency, and easier integration with automation systems, making them suitable for applications requiring accurate positioning and variable speed. The main differences lie in power source, control precision, maintenance needs, and suitability for specific industrial conditions.

Performance Comparison: Speed, Force, and Precision

Pneumatic actuators excel in high-speed operations and generate substantial force, making them ideal for applications requiring rapid movement and strong output. Electric actuators provide superior precision and controllability, offering fine-tuned positioning and consistent repeatability essential for tasks demanding accuracy. Your choice between pneumatic and electric actuators depends on balancing the need for speed and force with the level of precision required in your specific application.

Energy Efficiency and Power Consumption

Pneumatic actuators typically consume more energy due to the continuous air compression required, resulting in lower overall energy efficiency compared to electric actuators. Electric actuators offer precise control and consume power only during motion, leading to significantly reduced power consumption in standby modes. Industrial applications favor electric actuators for their superior energy savings and lower operational costs over time.

Installation and Maintenance Requirements

Pneumatic actuators require compressed air supply systems with regular inspection and filter replacement to prevent contamination, making their installation dependent on existing plant air infrastructure. Electric actuators involve simpler electrical wiring and calibration but need periodic lubrication and checking of motor and gearbox components to ensure optimal performance. Maintenance for pneumatic actuators tends to be more frequent due to air system wear, while electric actuators benefit from longer service intervals and easier troubleshooting with diagnostic tools.

Applications: Where to Use Each Actuator Type

Pneumatic actuators excel in industrial environments requiring fast, repetitive motion and high force, such as in automated manufacturing, valve control, and packaging systems. Electric actuators are ideal for applications demanding precise position control, variable speed, and energy efficiency, including robotics, HVAC systems, and medical devices. Your choice depends on the need for speed, control accuracy, and available power sources in the specific application.

Cost Analysis: Initial and Long-Term Expenses

Pneumatic actuators typically have lower initial costs due to simpler design and widespread availability of compressed air systems, making them budget-friendly for industrial applications. Electric actuators, while more expensive upfront because of complex electronics and motors, often offer reduced long-term expenses through higher energy efficiency, precise control, and minimal maintenance requirements. Your choice should consider total cost of ownership, balancing initial investment against operational savings in energy and maintenance over time.

Choosing the Right Actuator for Your Application

Pneumatic actuators offer rapid response and high force output, making them ideal for applications requiring fast, repetitive motion and operation in hazardous environments. Electric actuators provide precise positioning, energy efficiency, and easy integration with automation systems, suitable for applications needing fine control and lower maintenance. Evaluating your application's speed, control accuracy, power source availability, and environmental conditions helps you choose the optimal actuator type.

Pneumatic actuator vs electric actuator Infographic

libmatt.com

libmatt.com