Wet separators use liquid, typically water, to separate particles based on density, making them ideal for handling fine materials and reducing dust. Dry separators rely on air or mechanical forces without liquids, providing efficient separation for coarse materials and environments where moisture is undesirable.

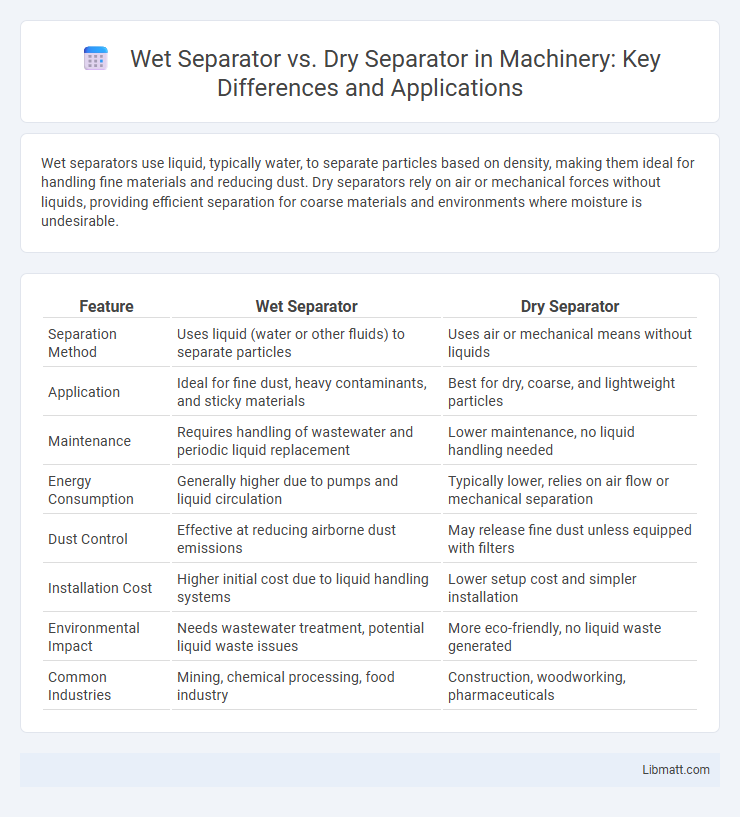

Table of Comparison

| Feature | Wet Separator | Dry Separator |

|---|---|---|

| Separation Method | Uses liquid (water or other fluids) to separate particles | Uses air or mechanical means without liquids |

| Application | Ideal for fine dust, heavy contaminants, and sticky materials | Best for dry, coarse, and lightweight particles |

| Maintenance | Requires handling of wastewater and periodic liquid replacement | Lower maintenance, no liquid handling needed |

| Energy Consumption | Generally higher due to pumps and liquid circulation | Typically lower, relies on air flow or mechanical separation |

| Dust Control | Effective at reducing airborne dust emissions | May release fine dust unless equipped with filters |

| Installation Cost | Higher initial cost due to liquid handling systems | Lower setup cost and simpler installation |

| Environmental Impact | Needs wastewater treatment, potential liquid waste issues | More eco-friendly, no liquid waste generated |

| Common Industries | Mining, chemical processing, food industry | Construction, woodworking, pharmaceuticals |

Introduction to Wet and Dry Separators

Wet separators utilize liquid, typically water, to separate particles or contaminants from gases or solids by leveraging density differences, making them ideal for dust and particulate removal in industrial processes. Dry separators, in contrast, rely on mechanical or air-based methods without liquid, offering efficient separation for applications requiring low moisture content or where water usage is restricted. Understanding the operational differences between wet and dry separators helps you choose the most effective technology for your specific separation needs.

Overview of Separation Technologies

Wet separators utilize liquid mediums, often water, to enhance particulate removal by leveraging density differences, making them effective for separating fine particles and sticky materials. Dry separators operate without liquids, relying on air flow, magnetic, or electrostatic forces to separate materials based on size, shape, or magnetic properties, suitable for applications sensitive to moisture. Selection between wet and dry separation technologies depends on factors such as material type, moisture sensitivity, environmental impact, and operational costs.

How Wet Separators Work

Wet separators work by using water or another liquid to capture and remove dust, particles, and contaminants from the air or gas stream. The liquid traps airborne impurities through impingement and agglomeration, causing heavier particles to settle out of the air flow. Your industrial process benefits from wet separators by achieving higher efficiency in pollutant removal, especially for fine dust and sticky materials.

How Dry Separators Work

Dry separators operate by employing centrifugal force or airflow to separate particles from gas streams without using water or liquid. These devices use mechanisms like cyclones, electrostatic precipitators, or fabric filters to efficiently capture and remove dust, ash, or other solid contaminants. Dry separation technology offers advantages in industries requiring moisture-free processes, such as power plants and cement manufacturing.

Key Differences Between Wet and Dry Separators

Wet separators use liquid, usually water, to capture and remove particles from gases, enhancing filtration efficiency by trapping contaminants in a liquid medium. Dry separators rely on mechanical methods such as centrifugal force or filters to separate particles without liquid, making them suitable for applications where moisture could damage equipment or processes. Your choice between wet and dry separators depends on factors like the type of contaminants, moisture tolerance, and environmental considerations.

Applications of Wet Separators

Wet separators are widely used in industries such as mining, chemical processing, and oil refining due to their effectiveness in separating fine particles from liquids through liquid-solid separation techniques. These separators excel in applications requiring dust suppression, moisture removal, and the handling of wet materials, making them essential for wastewater treatment and slurry processing. Their ability to handle high moisture content and enhance particle capture efficiency distinguishes them from dry separators in applications involving wet or sticky feedstocks.

Applications of Dry Separators

Dry separators are widely used in industries such as mining, agriculture, and food processing for efficient particle separation without the need for liquids. Their applications include separating solid particles from air or gas streams, dust collection, and sorting dry bulk materials, which makes them ideal for environments where moisture can cause contamination or product damage. Your choice of a dry separator enhances operational efficiency by reducing maintenance and preventing corrosion associated with wet systems.

Advantages of Wet vs Dry Separators

Wet separators offer superior dust suppression and improved air quality by using water to capture fine particulate matter, making them ideal for environments requiring efficient contaminant removal. They typically provide higher dust collection efficiency compared to dry separators, which can struggle with very fine particles and generate secondary dust during disposal. You benefit from reduced maintenance and longer equipment lifespan with wet separators due to less abrasive wear and lower risk of filter clogging.

Challenges and Limitations

Wet separators face challenges such as increased maintenance due to moisture buildup, risk of corrosion, and higher operational costs linked to water handling and disposal. Dry separators can struggle with dust collection efficiency, potential filter clogging, and require frequent cleaning, impacting performance and durability. Understanding your specific application needs helps determine which separator's limitations are manageable for optimal system reliability.

Choosing the Right Separator for Your Needs

Choosing between a wet separator and a dry separator depends on the specific application and material characteristics. Wet separators excel in removing fine particles and contaminants through liquid mediums, ideal for industries like mining and wastewater treatment. Dry separators offer efficient separation without moisture, suitable for handling dry powders and granules in sectors such as pharmaceuticals and food processing.

Wet separator vs dry separator Infographic

libmatt.com

libmatt.com