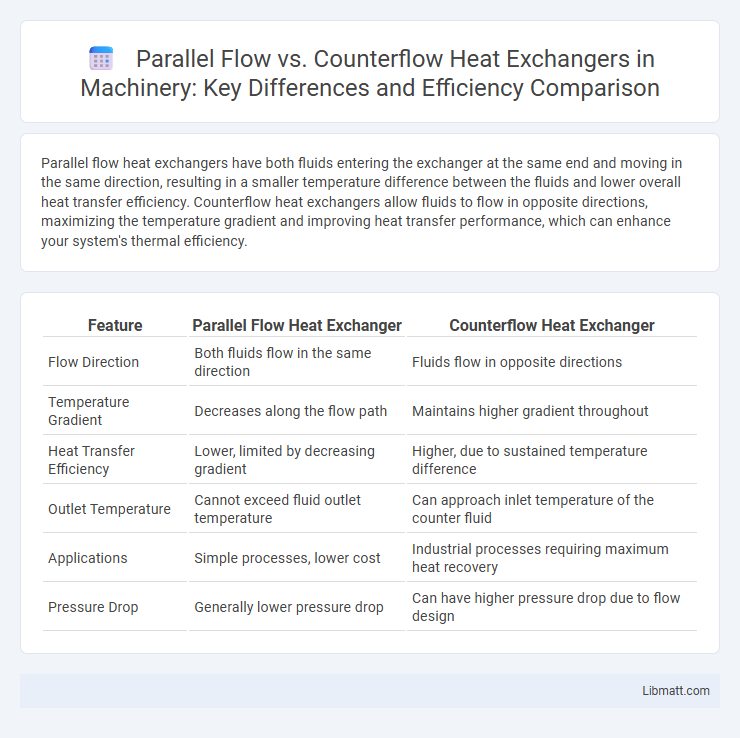

Parallel flow heat exchangers have both fluids entering the exchanger at the same end and moving in the same direction, resulting in a smaller temperature difference between the fluids and lower overall heat transfer efficiency. Counterflow heat exchangers allow fluids to flow in opposite directions, maximizing the temperature gradient and improving heat transfer performance, which can enhance your system's thermal efficiency.

Table of Comparison

| Feature | Parallel Flow Heat Exchanger | Counterflow Heat Exchanger |

|---|---|---|

| Flow Direction | Both fluids flow in the same direction | Fluids flow in opposite directions |

| Temperature Gradient | Decreases along the flow path | Maintains higher gradient throughout |

| Heat Transfer Efficiency | Lower, limited by decreasing gradient | Higher, due to sustained temperature difference |

| Outlet Temperature | Cannot exceed fluid outlet temperature | Can approach inlet temperature of the counter fluid |

| Applications | Simple processes, lower cost | Industrial processes requiring maximum heat recovery |

| Pressure Drop | Generally lower pressure drop | Can have higher pressure drop due to flow design |

Introduction to Heat Exchangers

Heat exchangers facilitate efficient thermal energy transfer between fluids, crucial in industrial and HVAC applications. Parallel flow heat exchangers feature fluids moving in the same direction, offering rapid temperature equalization but lower thermal efficiency. Counterflow heat exchangers, with fluids flowing in opposite directions, maximize temperature gradients and enhance heat transfer, making them ideal for high-performance thermal management systems.

Overview of Parallel Flow Heat Exchangers

Parallel flow heat exchangers feature both hot and cold fluids entering the exchanger at the same end and flowing in the same direction, enhancing initial temperature gradients. This design facilitates rapid heat transfer near the inlet but results in a smaller temperature difference along the flow path, leading to lower overall thermal efficiency compared to counterflow exchangers. Commonly used in applications requiring simplified construction and reduced pressure drop, parallel flow heat exchangers are suitable for processes with moderate temperature ranges.

Overview of Counterflow Heat Exchangers

Counterflow heat exchangers maximize thermal efficiency by positioning the hot and cold fluids to flow in opposite directions, enabling a greater temperature gradient along the exchanger length. This design allows the outlet temperature of the cold fluid to approach the inlet temperature of the hot fluid, improving heat transfer efficiency compared to parallel flow configurations. Your system can benefit from reduced energy consumption and enhanced thermal performance by employing counterflow heat exchangers.

Principle of Operation: Parallel vs Counterflow

In parallel flow heat exchangers, both fluids enter the exchanger at the same end and move in the same direction, resulting in a rapid temperature equalization but limited overall temperature difference. Counterflow heat exchangers have fluids moving in opposite directions, maintaining a higher temperature gradient along the length of the exchanger for improved heat transfer efficiency. The counterflow arrangement achieves closer outlet temperatures and higher thermal performance compared to the parallel flow configuration.

Heat Transfer Efficiency Comparison

Counterflow heat exchangers exhibit higher heat transfer efficiency than parallel flow designs due to the temperature gradient maintained throughout the length of the exchanger. In counterflow configurations, the hot and cold fluids move in opposite directions, maximizing the temperature difference and enabling greater thermal energy exchange. Parallel flow heat exchangers experience a rapid decline in temperature difference along the flow path, resulting in lower overall heat transfer efficiency.

Temperature Profiles and Limitations

In parallel flow heat exchangers, both fluids enter the exchanger at the same end and move in the same direction, resulting in rapid temperature approach but limited maximum heat transfer due to diminishing temperature difference along the length. Counterflow heat exchangers allow fluids to flow in opposite directions, maintaining a higher temperature gradient over the entire exchanger, which enhances heat transfer efficiency and allows outlet temperatures to approach the inlet temperature of the opposing fluid. However, parallel flow configurations have lower risk of thermal stress and fouling, while counterflow designs may face challenges in manufacturing complexity and higher pressure drops.

Pressure Drop Considerations

Counterflow heat exchangers typically experience a higher pressure drop than parallel flow designs due to the longer flow path and tighter channel configurations, which can affect pump sizing and energy consumption. Parallel flow arrangements offer lower pressure drops since the fluids move in the same direction, enabling simpler flow paths but potentially sacrificing thermal efficiency. Understanding your system's pressure drop limitations is crucial for selecting the appropriate heat exchanger type to balance energy use and heat transfer performance.

Applications of Parallel and Counterflow Heat Exchangers

Parallel flow heat exchangers are commonly used in applications requiring rapid temperature equalization, such as automotive radiators and low-temperature heating systems. Counterflow heat exchangers excel in high-efficiency heat transfer scenarios, including power plants, chemical processing, and HVAC systems, where maximizing thermal gradient and energy recovery is critical. The superior thermal performance of counterflow designs makes them ideal for industries focused on reducing operational costs and improving energy efficiency.

Pros and Cons of Each Flow Arrangement

Parallel flow heat exchangers offer simpler design and lower cost due to both fluids entering the heat exchanger at the same end and moving in the same direction, but they generally have lower heat transfer efficiency and limited temperature difference between the fluids. Counterflow heat exchangers provide superior thermal performance by allowing fluids to flow in opposite directions, resulting in a higher temperature gradient and more effective heat transfer, but they can be more complex and expensive to manufacture. The choice between parallel and counterflow configurations depends on balancing heat transfer efficiency with cost and design simplicity.

Selecting the Right Heat Exchanger Flow Type

Selecting the right heat exchanger flow type depends on your specific thermal efficiency and temperature requirements. Counterflow heat exchangers provide a higher heat transfer rate and closer temperature approach, making them ideal for applications needing maximum temperature difference. Parallel flow heat exchangers offer simpler design and uniform temperature gradient, suitable for processes with limited temperature change demands.

Parallel flow vs counterflow heat exchanger Infographic

libmatt.com

libmatt.com