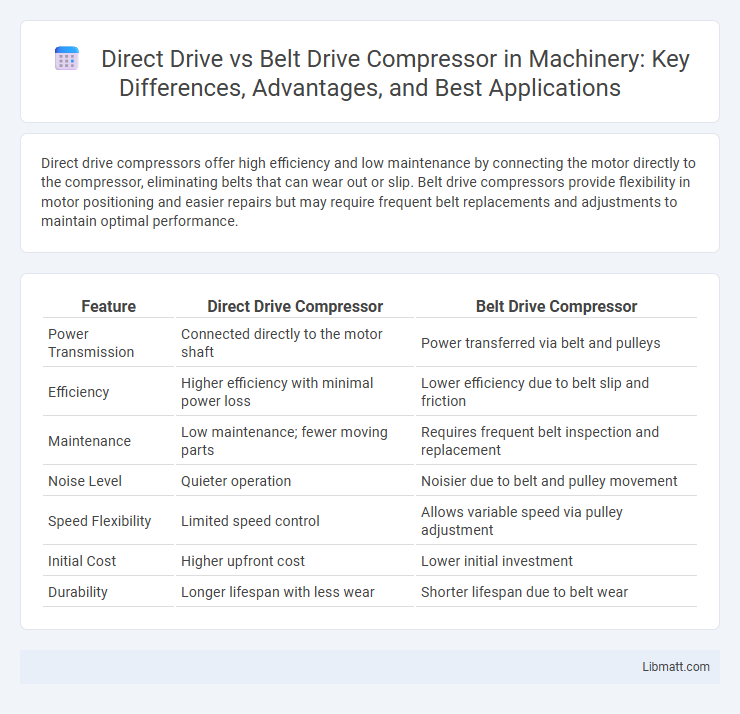

Direct drive compressors offer high efficiency and low maintenance by connecting the motor directly to the compressor, eliminating belts that can wear out or slip. Belt drive compressors provide flexibility in motor positioning and easier repairs but may require frequent belt replacements and adjustments to maintain optimal performance.

Table of Comparison

| Feature | Direct Drive Compressor | Belt Drive Compressor |

|---|---|---|

| Power Transmission | Connected directly to the motor shaft | Power transferred via belt and pulleys |

| Efficiency | Higher efficiency with minimal power loss | Lower efficiency due to belt slip and friction |

| Maintenance | Low maintenance; fewer moving parts | Requires frequent belt inspection and replacement |

| Noise Level | Quieter operation | Noisier due to belt and pulley movement |

| Speed Flexibility | Limited speed control | Allows variable speed via pulley adjustment |

| Initial Cost | Higher upfront cost | Lower initial investment |

| Durability | Longer lifespan with less wear | Shorter lifespan due to belt wear |

Introduction to Air Compressors

Direct drive air compressors connect the motor directly to the compressor pump, offering higher efficiency, reduced maintenance, and quieter operation. Belt drive compressors use a belt and pulley system to transfer power from the motor to the pump, allowing for variable speed control and easier motor replacement. Choice between direct drive and belt drive depends on application needs, such as continuous operation requirements and maintenance preferences.

What is a Direct Drive Compressor?

A direct drive compressor connects the motor directly to the compressor pump, eliminating the need for belts or pulleys, which enhances efficiency and reduces maintenance requirements. This design offers quieter operation and improved reliability due to fewer moving parts prone to wear and tear. Your choice of a direct drive compressor ensures consistent power delivery and lower operational costs compared to belt drive systems.

Understanding Belt Drive Compressors

Belt drive compressors use a flexible belt to connect the motor to the compressor pump, allowing for adjustable speeds and reduced noise levels compared to direct drive models. They are favored in applications requiring lower maintenance costs and longer lifespan because the belt absorbs vibrations and minimizes wear on the motor. Regular inspection and tension adjustment of the belt are crucial for maintaining optimal performance and preventing unexpected downtime.

Key Differences: Direct Drive vs Belt Drive

Direct drive compressors connect the motor directly to the pump, offering higher efficiency, lower maintenance, and reduced energy loss due to fewer moving parts. Belt drive compressors use a belt and pulley system, allowing for quieter operation and easier motor replacement but requiring regular belt tension checks and potential belt replacements. Your choice depends on prioritizing efficiency and low maintenance (direct drive) or noise reduction and service flexibility (belt drive).

Efficiency and Performance Comparison

Direct drive compressors offer higher efficiency by eliminating energy losses caused by belts and pulleys, resulting in better power transfer and reduced maintenance requirements. Belt drive compressors, while typically less efficient due to belt slippage and wear, provide flexibility in speed control and can absorb shock loads, which may extend equipment life under variable operating conditions. Performance-wise, direct drive models deliver consistent, reliable output with lower noise levels, making them ideal for energy-conscious applications, whereas belt drive compressors excel in heavy-duty environments requiring variable speed and torque adjustments.

Maintenance Requirements of Each Type

Direct drive compressors require less maintenance due to fewer moving parts and no belts that can wear or slip, reducing downtime and repair costs. Belt drive compressors need regular inspection and adjustment of belt tension, periodic replacement of belts, and alignment checks to maintain optimal performance. The maintenance frequency for belt drives is generally higher, impacting long-term operational efficiency compared to the more durable direct drive systems.

Noise Levels and Vibration

Direct drive compressors operate with fewer moving parts, resulting in significantly lower noise levels and reduced vibration compared to belt drive compressors. Belt drive compressors generate more noise due to the friction and tension in the belt system, causing increased vibration that can affect operational stability. For applications requiring quieter performance and minimal vibration, direct drive compressors are the preferred choice.

Durability and Longevity

Direct drive compressors offer enhanced durability and longevity due to fewer moving parts, reducing wear and tear over time. Belt drive compressors often require regular belt replacements and adjustments, which can lead to increased maintenance and potential downtime. Choosing a direct drive system can improve your equipment's lifespan and reliability in demanding industrial applications.

Ideal Applications for Each Compressor Type

Direct drive compressors are ideal for applications requiring compact design, high efficiency, and low maintenance, such as in medical equipment, dental offices, and small workshops where clean and reliable air is essential. Belt drive compressors suit heavy-duty industrial environments like manufacturing plants and automotive shops, offering durability and easier maintenance with less vibration for prolonged continuous operation. You should choose direct drive for precision and quiet use, while belt drive excels in versatile, high-capacity tasks.

Choosing the Right Compressor for Your Needs

Direct drive compressors provide higher efficiency and lower maintenance by eliminating belts, making them ideal for industrial applications requiring consistent, high-performance operation. Belt drive compressors offer greater flexibility in speed adjustment and quieter operation, suitable for lighter-duty or variable speed tasks. Evaluating your workload demands, space constraints, and noise considerations helps determine which compressor type optimally supports your specific requirements.

Direct drive vs belt drive compressor Infographic

libmatt.com

libmatt.com