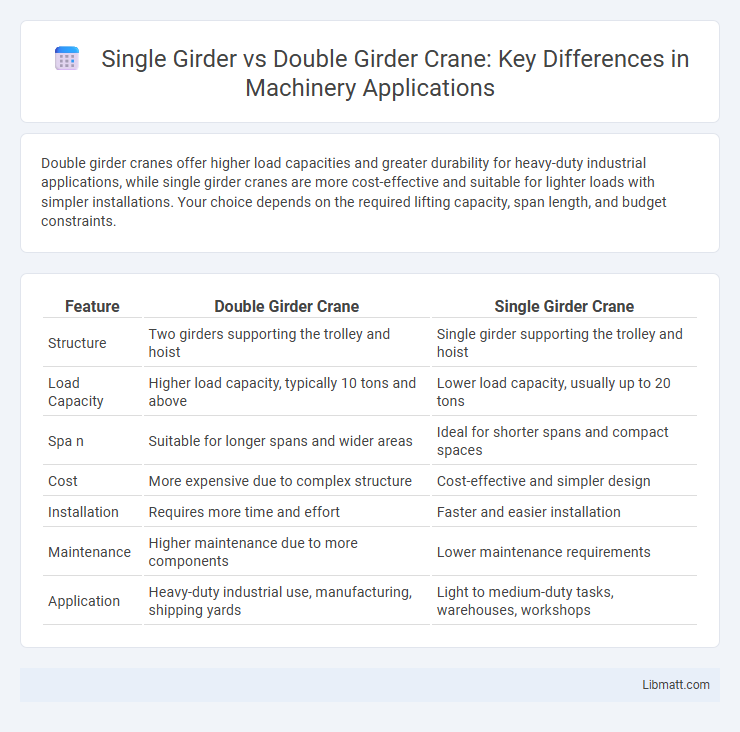

Double girder cranes offer higher load capacities and greater durability for heavy-duty industrial applications, while single girder cranes are more cost-effective and suitable for lighter loads with simpler installations. Your choice depends on the required lifting capacity, span length, and budget constraints.

Table of Comparison

| Feature | Double Girder Crane | Single Girder Crane |

|---|---|---|

| Structure | Two girders supporting the trolley and hoist | Single girder supporting the trolley and hoist |

| Load Capacity | Higher load capacity, typically 10 tons and above | Lower load capacity, usually up to 20 tons |

| Spa n | Suitable for longer spans and wider areas | Ideal for shorter spans and compact spaces |

| Cost | More expensive due to complex structure | Cost-effective and simpler design |

| Installation | Requires more time and effort | Faster and easier installation |

| Maintenance | Higher maintenance due to more components | Lower maintenance requirements |

| Application | Heavy-duty industrial use, manufacturing, shipping yards | Light to medium-duty tasks, warehouses, workshops |

Introduction to Overhead Cranes

Overhead cranes are essential for material handling in industrial environments, where double girder cranes offer greater lifting capacity and stability compared to single girder cranes. Single girder cranes are typically used for lighter loads and simpler applications, providing cost efficiency and easier installation. Your choice between these cranes depends on the required load capacity, workspace limitations, and operational demands.

What is a Single Girder Crane?

A single girder crane features one main beam that supports the hoist, making it lighter and more suitable for moderate lifting tasks up to 20 tons typically used in smaller workshops or warehouses. Its simplified design allows for easier installation and maintenance compared to double girder cranes, which have two parallel beams for heavier loads. Single girder cranes offer cost-effective solutions with efficient performance where space and weight capacity requirements are limited.

What is a Double Girder Crane?

A double girder crane features two parallel girders that support the trolley, allowing for higher lifting capacity and longer spans compared to single girder cranes. This design enhances stability and durability, making it ideal for heavy-duty industrial applications requiring precise handling of oversized loads. Double girder cranes often incorporate advanced components like heavier duty end trucks and hoists, which contribute to their superior performance in demanding environments.

Key Structural Differences

Double girder cranes feature two main beams supporting the hoist mechanism, offering increased load capacity and stability, while single girder cranes use only one beam, making them lighter and more cost-effective for moderate loads. The double girder design allows for a wider span and better distribution of weight, which enhances safety and durability in heavy-duty industrial applications. Your choice depends on the required lifting capacity, span, and the complexity of the tasks within your facility.

Load Capacity Comparison

Double girder cranes typically offer higher load capacities ranging from 10 tons to over 100 tons, making them ideal for heavy-duty lifting in industrial settings. Single girder cranes generally support lighter loads, usually up to 20 tons, suitable for moderate lifting tasks with a more compact design. Your choice should align with the specific load requirements and operational demands of your facility to ensure safety and efficiency.

Span and Lifting Height Differences

Double girder cranes typically offer a longer span and greater lifting height compared to single girder cranes, making them ideal for heavy-duty industrial applications. The design of double girder cranes allows the hoist to be mounted on top of the girders, maximizing hook height and enabling a wider span between supports. Single girder cranes generally have a lower lifting height due to the hoist being suspended beneath the girder, which limits the overall working space.

Installation and Maintenance Considerations

Double girder cranes typically require more complex installation due to their heavier structure and additional components, demanding a robust support system and longer assembly time. Maintenance for double girder cranes involves inspecting multiple mechanical parts and electrical systems, which can increase downtime but allows handling of heavier loads safely. Your choice depends on balancing the need for load capacity with the available resources for installation and ongoing maintenance.

Cost Analysis: Single vs Double Girder

Single girder cranes typically offer lower initial investment and reduced installation costs due to fewer materials and simpler design compared to double girder cranes. Double girder cranes provide higher load capacity and enhanced durability, which can lead to lower maintenance expenses and longer service life, potentially offsetting the higher upfront cost over time. Evaluating total cost of ownership including procurement, operation, and maintenance is crucial for selecting the optimal crane type for specific industrial applications.

Applications and Industry Use Cases

Double girder cranes are commonly used in heavy-duty industries such as steel manufacturing, shipyards, and large construction projects where lifting capacities exceed 20 tons and extended spans are required. Single girder cranes serve lighter industrial applications including warehouses, automotive assembly lines, and maintenance facilities, typically handling loads up to 10 tons with easier installation and cost efficiency. Your choice between these crane types depends on the specific operational demands, load capacity, and spatial constraints of the industrial environment.

Choosing the Right Crane for Your Needs

Selecting between a double girder crane and a single girder crane depends on load capacity, span length, and operational requirements. Double girder cranes offer higher load capacities and longer spans, making them suitable for heavy-duty industrial applications. Single girder cranes are more cost-effective and easier to install, ideal for lighter loads and shorter spans in smaller facilities.

Double girder crane vs single girder crane Infographic

libmatt.com

libmatt.com