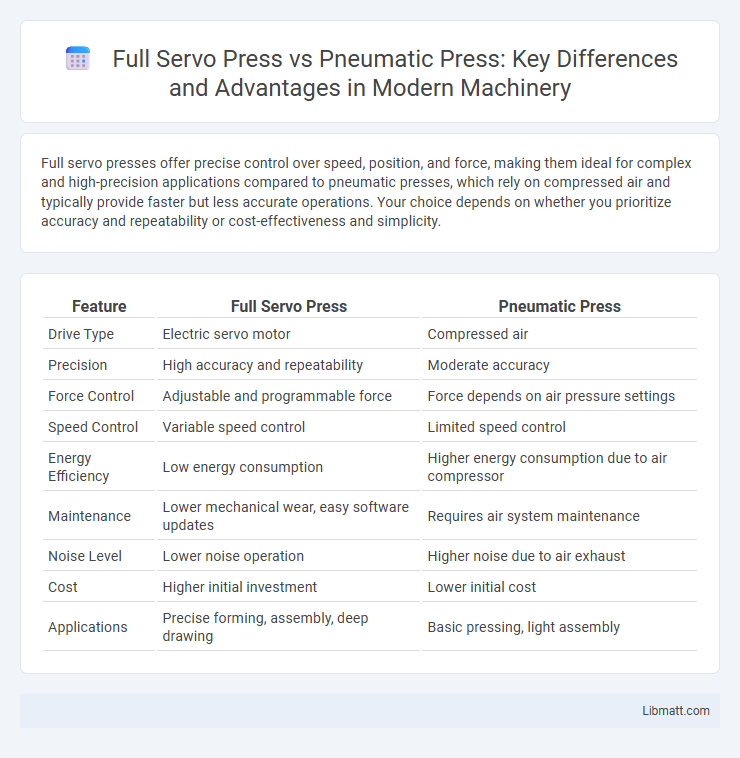

Full servo presses offer precise control over speed, position, and force, making them ideal for complex and high-precision applications compared to pneumatic presses, which rely on compressed air and typically provide faster but less accurate operations. Your choice depends on whether you prioritize accuracy and repeatability or cost-effectiveness and simplicity.

Table of Comparison

| Feature | Full Servo Press | Pneumatic Press |

|---|---|---|

| Drive Type | Electric servo motor | Compressed air |

| Precision | High accuracy and repeatability | Moderate accuracy |

| Force Control | Adjustable and programmable force | Force depends on air pressure settings |

| Speed Control | Variable speed control | Limited speed control |

| Energy Efficiency | Low energy consumption | Higher energy consumption due to air compressor |

| Maintenance | Lower mechanical wear, easy software updates | Requires air system maintenance |

| Noise Level | Lower noise operation | Higher noise due to air exhaust |

| Cost | Higher initial investment | Lower initial cost |

| Applications | Precise forming, assembly, deep drawing | Basic pressing, light assembly |

Introduction to Full Servo and Pneumatic Presses

Full servo presses integrate digitally controlled servo motors to deliver precise force and speed control, enhancing accuracy in complex manufacturing processes. Pneumatic presses operate using compressed air to generate force, offering simplicity and cost-effectiveness for less precision-demanding applications. Choosing between these presses depends on factors like precision requirements, production speed, and operational flexibility.

Overview: Full Servo Press Technology

Full servo press technology utilizes brushless servo motors to deliver precise and programmable control over speed, force, and position during pressing operations, outperforming pneumatic presses which rely on compressed air for motion. This technology enhances energy efficiency and repeatability by offering accurate force feedback and customizable motion profiles tailored to specific manufacturing needs. Full servo presses provide superior stroke control and consistent performance, making them ideal for complex applications requiring high precision and reduced cycle times.

Overview: Pneumatic Press Technology

Pneumatic press technology utilizes compressed air to generate force, offering rapid cycling speeds and straightforward operation ideal for high-volume production. These presses are favored for their cost-effectiveness and ease of maintenance, especially in applications requiring consistent pressure without complex control systems. However, pneumatic presses typically lack the precision and adjustable force control found in full servo presses, making them less suitable for delicate or intricate forming processes.

Key Differences Between Full Servo and Pneumatic Presses

Full servo presses utilize electric motors for precise control of speed, position, and force, enabling high accuracy and repeatability in complex stamping or forming operations. Pneumatic presses operate using compressed air, offering simpler design and lower initial costs but limited control over force and speed, resulting in less precision and slower cycle times. The full servo press provides energy efficiency and programmability benefits, whereas pneumatic presses excel in applications requiring rapid, high-force strokes with minimal control complexity.

Precision and Control: Servo vs Pneumatic

Full servo presses deliver superior precision and control by using programmable servo motors, enabling precise adjustment of force, speed, and position throughout the pressing cycle. Pneumatic presses rely on compressed air, limiting consistency due to variations in air pressure and reduced ability to finely control stroke speed and force. The advanced feedback systems in servo presses ensure exact repeatability and accuracy, making them ideal for high-precision manufacturing applications.

Energy Efficiency Comparison

Full servo presses offer significantly higher energy efficiency compared to pneumatic presses by precisely controlling motor speed and torque, reducing power consumption during idle and low-load conditions. Pneumatic presses typically waste energy due to constant air compression and leaks, leading to increased operational costs. Optimizing Your production with a full servo press can result in substantial energy savings and lower overall expenses.

Maintenance Requirements and Costs

Full servo presses have lower maintenance requirements and costs due to fewer mechanical components and no need for air compressors or pneumatic lines, resulting in less wear and tear. Pneumatic presses require regular inspection and replacement of seals, valves, and air filters, which increases downtime and maintenance expenses. The advanced control and diagnostics in full servo presses also help predict maintenance needs, reducing unexpected failures and prolonging equipment life.

Applications and Industry Use Cases

Full servo presses offer precise control and repeatability, making them ideal for intricate applications in automotive manufacturing, electronics assembly, and medical device production where accuracy and flexibility are critical. Pneumatic presses are preferred in industries such as packaging, light metal forming, and plastic molding, where rapid cycling and lower initial costs are essential for high-volume, less complex operations. Your choice depends on the need for precision versus speed and cost, with full servo presses excelling in custom, detailed tasks and pneumatic presses suiting straightforward, high-throughput processes.

Pros and Cons: Full Servo Presses

Full servo presses offer precise control over speed, force, and position, enabling high repeatability and excellent part quality in manufacturing processes. Their energy efficiency and programmability reduce operational costs but come with higher initial investment and maintenance complexity compared to pneumatic presses. The dependence on electrical components can lead to downtime if power issues arise, which requires skilled technicians for troubleshooting and repairs.

Pros and Cons: Pneumatic Presses

Pneumatic presses offer advantages such as lower initial cost, simpler design, and fast cycle times, making them ideal for high-speed, low-force applications. However, they lack precise force control and repeatability compared to full servo presses, limiting their use in complex or delicate tasks. Your choice depends on whether consistent accuracy or cost-efficiency is the primary requirement.

Full servo press vs pneumatic press Infographic

libmatt.com

libmatt.com