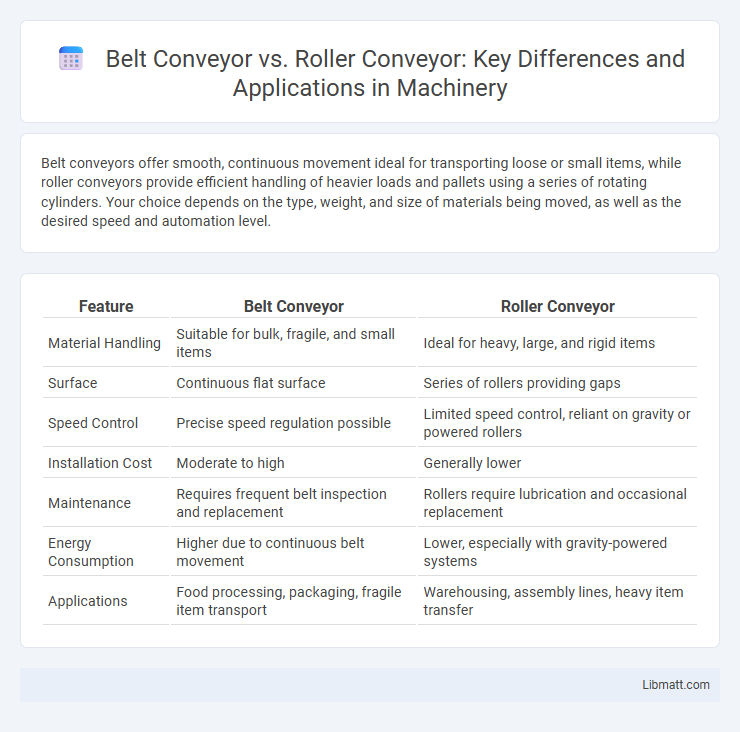

Belt conveyors offer smooth, continuous movement ideal for transporting loose or small items, while roller conveyors provide efficient handling of heavier loads and pallets using a series of rotating cylinders. Your choice depends on the type, weight, and size of materials being moved, as well as the desired speed and automation level.

Table of Comparison

| Feature | Belt Conveyor | Roller Conveyor |

|---|---|---|

| Material Handling | Suitable for bulk, fragile, and small items | Ideal for heavy, large, and rigid items |

| Surface | Continuous flat surface | Series of rollers providing gaps |

| Speed Control | Precise speed regulation possible | Limited speed control, reliant on gravity or powered rollers |

| Installation Cost | Moderate to high | Generally lower |

| Maintenance | Requires frequent belt inspection and replacement | Rollers require lubrication and occasional replacement |

| Energy Consumption | Higher due to continuous belt movement | Lower, especially with gravity-powered systems |

| Applications | Food processing, packaging, fragile item transport | Warehousing, assembly lines, heavy item transfer |

Overview of Belt Conveyors and Roller Conveyors

Belt conveyors use a continuous loop of material to transport goods, ideal for moving irregularly shaped or fragile items with smooth, controlled motion. Roller conveyors consist of a series of rolling cylinders that facilitate the movement of products using gravity or mechanical power, offering excellent durability and easy maintenance for heavy-duty applications. Understanding your material handling needs helps determine whether a belt conveyor's consistent surface or a roller conveyor's robust design best suits your operation.

Key Differences Between Belt and Roller Conveyors

Belt conveyors use a continuous loop of material to move products smoothly, making them ideal for transporting irregular or fragile items over long distances. Roller conveyors consist of a series of rollers that allow items to be pushed, pulled, or moved by gravity, providing efficient handling for heavy, rigid objects with flat bottoms. Your choice depends on factors like load type, distance, and the need for controlled motion or accumulation.

Material Handling Applications Comparison

Belt conveyors excel in transporting fragile or loose materials over long distances with consistent speed, making them ideal for bulk handling and packaging industries. Roller conveyors offer superior performance in handling heavy or rigid items, enabling easy accumulation and sorting in assembly lines and warehouses. Your choice depends on load type, application requirements, and the need for smooth or segmented movement within material handling processes.

Load Capacity: Which Conveyor Handles More?

Belt conveyors typically handle heavier loads with capacities ranging from 200 to 2,000 kilograms per meter, making them ideal for transporting bulk materials or heavy packages. Roller conveyors usually support lighter to moderate loads, generally up to 500 kilograms per section, and excel in moving individual items or palletized goods. The choice depends on the specific application, with belt conveyors preferred for high load capacity and roller conveyors favored for ease of movement and sorting.

Conveyor Speed: Belt vs Roller Performance

Belt conveyors typically offer consistent and controllable speeds, ranging from 0.5 to 5 meters per second, suited for smooth material transport over long distances. Roller conveyors, especially gravity or motor-driven types, vary widely in speed capabilities, often limited by roller friction and load, generally supporting speeds up to 2 meters per second. Belt conveyors outperform roller conveyors in high-speed, continuous handling applications, while roller conveyors excel in flexible accumulation and sorting tasks with moderate speed requirements.

Suitability for Various Product Types

Belt conveyors are ideal for transporting a wide range of product types, including small, loose, or irregularly shaped items, as they provide a continuous, smooth surface that prevents product damage and spillage. Roller conveyors excel in moving heavy, rigid, or palletized goods, where stability and ease of loading and unloading are critical, making them suitable for warehouses and manufacturing plants. Both conveyor types offer distinct advantages based on product size, weight, handling requirements, and environmental conditions.

Maintenance Requirements and Costs

Belt conveyors generally require more frequent maintenance due to the need for regular belt alignment, tension adjustments, and replacement of worn belts, which can increase overall operational costs. Roller conveyors have lower maintenance demands since their components, like rollers and bearings, are easier to service and replace, resulting in reduced downtime and maintenance expenses. Your choice between the two should consider long-term maintenance budgets and the availability of technical support for efficient operation.

Energy Efficiency: Belt vs Roller Systems

Belt conveyors typically consume more energy due to continuous belt movement requiring constant motor power, while roller conveyors, especially gravity roller types, use less energy as items move with minimal motor assistance. Motorized roller conveyors often balance energy use by only activating rollers under load, enhancing efficiency compared to standard belt systems. Energy savings can reach up to 30% with roller conveyors in suitable applications, making them favorable for reducing operational costs.

Installation Considerations and Space Requirements

Belt conveyors require more precise alignment and tension adjustments during installation, often needing a flat, stable surface to ensure smooth operation, while roller conveyors offer easier installation with modular components that can be configured to fit various layouts. Space requirements for belt conveyors tend to be more compact due to their continuous surface, making them suitable for tight or confined areas, whereas roller conveyors may demand additional space for support frames and spacing between rollers. Your choice should consider the available installation environment and spatial constraints to maximize efficiency and ease of maintenance.

Choosing the Right Conveyor for Your Operation

Choosing the right conveyor depends on the specific needs of your operation, such as load type, weight, and space constraints. Belt conveyors are ideal for transporting bulk materials and irregularly shaped items smoothly over long distances, offering consistent speed and minimal slippage. Roller conveyors excel in moving heavy, unit loads with low friction, making them perfect for assembly lines and pallet handling in compact areas.

Belt conveyor vs roller conveyor Infographic

libmatt.com

libmatt.com