LVDT (Linear Variable Differential Transformer) and RVDT (Rotary Variable Differential Transformer) are precise sensors used to measure displacement; LVDT measures linear movement while RVDT measures angular displacement. Your choice depends on whether you need to detect straight-line position changes or rotational angles in an application.

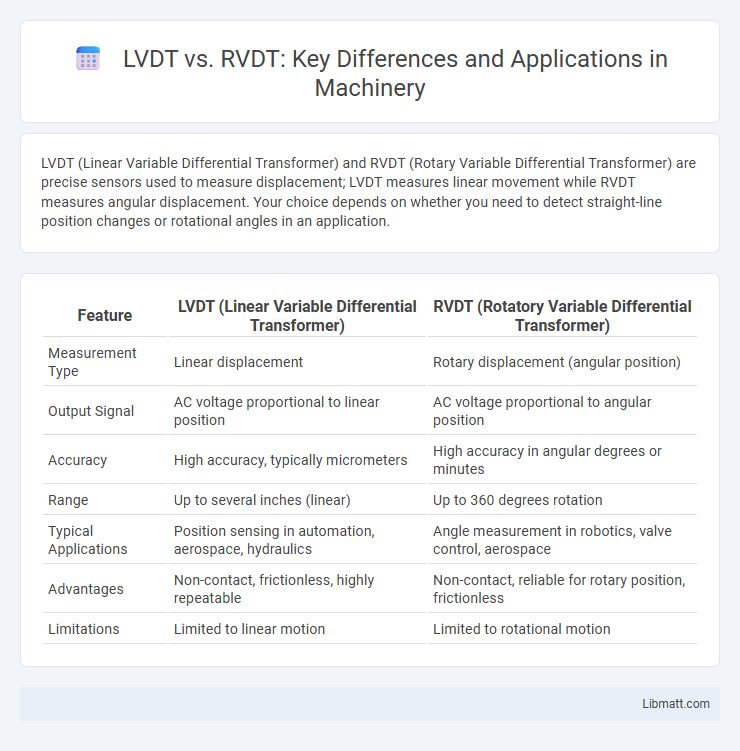

Table of Comparison

| Feature | LVDT (Linear Variable Differential Transformer) | RVDT (Rotatory Variable Differential Transformer) |

|---|---|---|

| Measurement Type | Linear displacement | Rotary displacement (angular position) |

| Output Signal | AC voltage proportional to linear position | AC voltage proportional to angular position |

| Accuracy | High accuracy, typically micrometers | High accuracy in angular degrees or minutes |

| Range | Up to several inches (linear) | Up to 360 degrees rotation |

| Typical Applications | Position sensing in automation, aerospace, hydraulics | Angle measurement in robotics, valve control, aerospace |

| Advantages | Non-contact, frictionless, highly repeatable | Non-contact, reliable for rotary position, frictionless |

| Limitations | Limited to linear motion | Limited to rotational motion |

Introduction to LVDT and RVDT

LVDT (Linear Variable Differential Transformer) and RVDT (Rotary Variable Differential Transformer) are electromechanical sensors used for precise measurement of linear and angular displacement respectively. LVDTs convert linear motion into a variable electrical signal, offering high accuracy and reliability in industrial automation, while RVDTs measure angular position through rotary motion, ideal for applications requiring rotational feedback. Your choice between LVDT and RVDT depends on the nature of displacement you need to measure -- linear or rotary.

Working Principle of LVDT

The Linear Variable Differential Transformer (LVDT) operates on the principle of electromagnetic induction, where a movable ferromagnetic core inside a coil assembly causes changes in mutual inductance between primary and secondary windings. When Your core position shifts, an alternating current in the primary coil induces voltages in the secondary coils, differing in magnitude and phase, allowing precise linear displacement measurement. This contactless sensing principle provides high accuracy, frictionless operation, and durability in industrial automation and control applications.

Working Principle of RVDT

The Rotary Variable Differential Transformer (RVDT) operates on the principle of electromagnetic induction, where an alternating current excites the primary winding, creating a magnetic flux that induces voltages in the secondary windings. As the rotor, connected to the shaft whose angular displacement is measured, turns, it differentially alters the magnetic coupling between the primary and secondary coils, causing a sine wave voltage output proportional to the angular position. Understanding the working principle of RVDT can enhance your ability to select the right sensor for precise angular displacement measurement in industrial automation and control systems.

Construction and Design Differences

LVDT (Linear Variable Differential Transformer) consists of a primary coil centered between two secondary coils, with a movable ferromagnetic core that shifts linearly to induce voltage changes corresponding to displacement; RVDT (Rotary Variable Differential Transformer), on the other hand, features a similar coil assembly but is designed with a rotor that rotates to vary the magnetic coupling between coils, producing an electrical output proportional to angular position. The LVDT's cylindrical core moves axially within a non-contact coil frame enabling precise linear measurements, whereas the RVDT's rotating shaft and coil arrangement accommodate angular sensing with high resolution and durability. Your choice between LVDT and RVDT depends on whether precise linear or rotational position feedback is required based on these fundamental construction and design distinctions.

Key Specifications and Performance

LVDTs (Linear Variable Differential Transformers) provide precise linear displacement measurements with high resolution, low hysteresis, and excellent repeatability over a wide range of stroke lengths, typically from a few millimeters to several centimeters. RVDTs (Rotary Variable Differential Transformers) excel in detecting angular displacement with high accuracy, rugged construction, and a linear output over typical ranges of +-30deg to +-360deg, making them ideal for rotational position sensing. Both sensors offer frictionless operation and infinite resolution but differ primarily in their measurement type--linear for LVDTs versus rotary for RVDTs--affecting their application in dynamic systems requiring robust, contactless sensing.

Advantages of LVDT

LVDTs (Linear Variable Differential Transformers) offer superior linearity and higher resolution compared to RVDTs (Rotary Variable Differential Transformers), making them ideal for precise linear position measurements. They exhibit excellent repeatability and durability in harsh environments due to their contactless magnetic core operation. These advantages enable LVDTs to deliver reliable, maintenance-free performance in industrial automation, aerospace, and robotics applications.

Advantages of RVDT

RVDTs offer rotational displacement measurement with high accuracy, making them ideal for angular position sensing in aerospace and industrial applications. They provide excellent linearity, frictionless operation, and enhanced durability due to their non-contact magnetic coupling, which reduces wear and extends sensor lifespan. Compared to LVDTs, RVDTs require less space and simplify integration when measuring rotary motions.

Common Applications of LVDT and RVDT

LVDTs (Linear Variable Differential Transformers) are commonly used in precision measurement of linear displacement in applications such as aerospace control systems, hydraulic cylinder position feedback, and material testing machines. RVDTs (Rotary Variable Differential Transformers) excel in measuring angular displacement and are widely utilized in robotics, aircraft control surface position sensing, and industrial automation for precise rotational feedback. Your choice between LVDT and RVDT depends on whether you need high accuracy linear or rotary position measurements for your specific application.

Comparison Table: LVDT vs RVDT

LVDT (Linear Variable Differential Transformer) and RVDT (Rotary Variable Differential Transformer) differ primarily in their measurement domains, with LVDT measuring linear displacement and RVDT detecting angular displacement. Both sensors operate on electromagnetic induction principles, offering high accuracy, durability, and frictionless operation, but LVDT excels in linear position applications while RVDT is optimized for rotary position sensing. Key comparison factors include output waveform type--LVDT producing linear voltage proportional to displacement versus RVDT generating sinusoidal voltage corresponding to angular position--making each suited for specific industrial automation needs.

Choosing the Right Sensor for Your Application

LVDT (Linear Variable Differential Transformer) excels in precise linear position measurement, while RVDT (Rotary Variable Differential Transformer) is ideal for accurate angular displacement sensing. Your choice depends on whether your application requires detecting linear or rotary motion, with LVDTs providing high repeatability and sensitivity for straight-line movements and RVDTs offering robust performance in rotary settings. Evaluating factors such as range, environmental conditions, and output requirements will help you select the optimal sensor type for reliable measurement.

LVDT vs RVDT Infographic

libmatt.com

libmatt.com