Split case pumps feature a horizontally split casing allowing easy access to internal components for maintenance without disturbing pipework, making them ideal for high-flow applications. End suction pumps have a single casing with suction at one end and discharge at the top, offering a compact design suitable for lower-flow, general-purpose pumping needs.

Table of Comparison

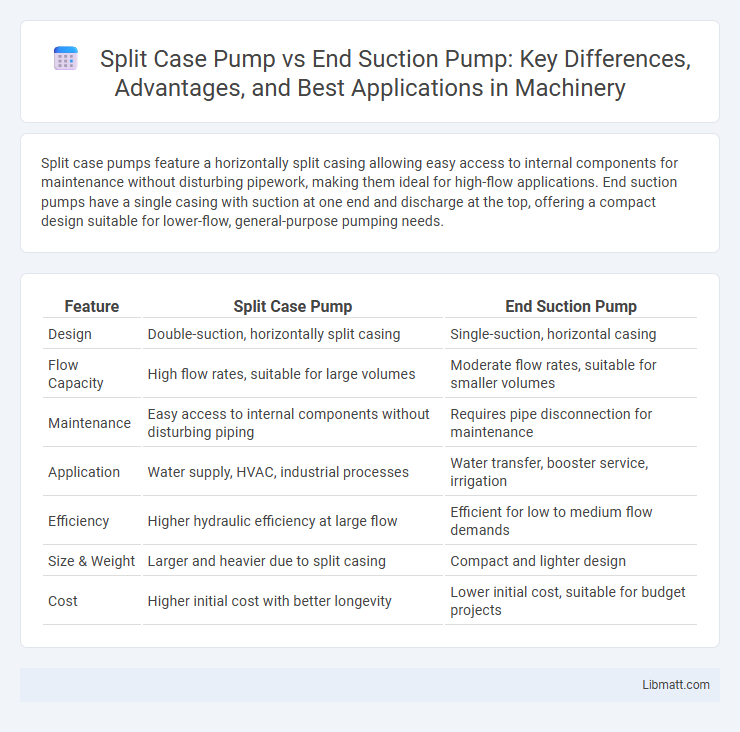

| Feature | Split Case Pump | End Suction Pump |

|---|---|---|

| Design | Double-suction, horizontally split casing | Single-suction, horizontal casing |

| Flow Capacity | High flow rates, suitable for large volumes | Moderate flow rates, suitable for smaller volumes |

| Maintenance | Easy access to internal components without disturbing piping | Requires pipe disconnection for maintenance |

| Application | Water supply, HVAC, industrial processes | Water transfer, booster service, irrigation |

| Efficiency | Higher hydraulic efficiency at large flow | Efficient for low to medium flow demands |

| Size & Weight | Larger and heavier due to split casing | Compact and lighter design |

| Cost | Higher initial cost with better longevity | Lower initial cost, suitable for budget projects |

Introduction to Split Case and End Suction Pumps

Split case pumps feature a horizontally split casing that allows easy access to internal components for maintenance, making them ideal for large-volume water transfer and industrial applications. End suction pumps have a single-suction impeller with the inlet on one side and the outlet on top, offering a compact design suitable for moderate flow rates and general-purpose use. Both types are centrifugal pumps but differ in structure, application scope, and maintenance convenience.

Basic Design and Construction Differences

Split case pumps feature a two-piece casing divided along a horizontal centerline, enabling easy access to internal components such as the impeller and shaft without disturbing the pipe connections. End suction pumps possess a single-piece volute casing with the suction nozzle aligned axially to the impeller and discharge nozzle positioned radially, requiring removal of the pump from the piping system for internal maintenance. The split case design typically offers higher flow rates with better serviceability, while the end suction pump is compact with a simpler construction tailored for lower flow and pressure applications.

Key Operating Principles

Split case pumps feature a horizontal casing split into two halves, allowing easy access to internal components for maintenance without disturbing the alignment. End suction pumps operate with a single casing where fluid enters the suction side and is discharged at the end, making them compact and suitable for moderate flow and pressure conditions. Understanding your system requirements helps determine whether the rugged, high-capacity design of split case pumps or the simpler, space-efficient end suction pumps best fits your application.

Performance and Efficiency Comparison

Split case pumps generally offer higher flow rates and improved efficiency in large-scale water transfer applications due to their robust design and reduced hydraulic losses. End suction pumps, while typically more compact and easier to maintain, often exhibit lower efficiency at higher flow rates and pressures because of their single-suction impeller design. Performance comparisons show split case pumps excel in handling higher volumes with greater energy savings, making them ideal for industrial and municipal systems requiring continuous, high-capacity pumping.

Space and Installation Requirements

Split case pumps feature a horizontally split casing enabling easier access for maintenance without disturbing the piping, which reduces downtime and allows installation in confined spaces. End suction pumps require more clearance for removal and maintenance since the casing is not split, often necessitating additional space around the pump for service. The compact design of end suction pumps is ideal for installations with limited footprint, whereas split case pumps are better suited for applications prioritizing ease of maintenance and minimal disruption during servicing.

Maintenance and Serviceability

Split case pumps feature a horizontally split casing that allows easy access to the internal components without disturbing the piping, significantly simplifying maintenance and reducing downtime. End suction pumps typically require more disassembly to access the impeller and internal parts, leading to longer maintenance periods and potential system interruptions. The robust design of split case pumps supports frequent inspections and repairs with minimal disruption, enhancing overall serviceability in industrial applications.

Cost Analysis: Initial and Lifecycle Costs

Split case pumps typically have higher initial costs due to their complex design and larger size compared to end suction pumps, which are generally more compact and economical to purchase. Over the lifecycle, split case pumps often incur lower maintenance costs because of their robust construction and easier access to internal components for repair, leading to extended service intervals and reduced downtime. End suction pumps may experience higher replacement part expenses and more frequent maintenance, potentially increasing total cost of ownership despite their lower upfront investment.

Typical Applications and Use Cases

Split case pumps are commonly used in large-scale water distribution, HVAC systems, and industrial applications requiring high flow rates and moderate pressures. End suction pumps are preferred for municipal water supply, agricultural irrigation, and chemical processing where space constraints and ease of maintenance are critical. Both pump types serve essential roles in fluid transfer, with split case pumps excelling in durability for continuous operation and end suction pumps offering versatility in smaller, controlled environments.

Advantages and Disadvantages Overview

Split case pumps offer advantages such as ease of maintenance due to their horizontally split casing, allowing quick access to internal components without disturbing pipe connections, and higher flow rates suitable for large volume applications. However, they tend to have a larger footprint and higher initial cost compared to end suction pumps, which are more compact, simpler in design, and generally more cost-effective for lower flow requirements. End suction pumps are less maintenance-intensive with fewer moving parts but may experience limitations in handling high pressures and large flow volumes that split case pumps manage more efficiently.

Selection Criteria for Optimal Pump Choice

When selecting between a split case pump and an end suction pump, consider flow rate, pressure requirements, and maintenance needs. Split case pumps are ideal for high flow, moderate pressure applications with ease of maintenance due to their two-piece casing design. Your choice should align with system efficiency, space constraints, and operational costs to ensure optimal pump performance and longevity.

Split case pump vs end suction pump Infographic

libmatt.com

libmatt.com