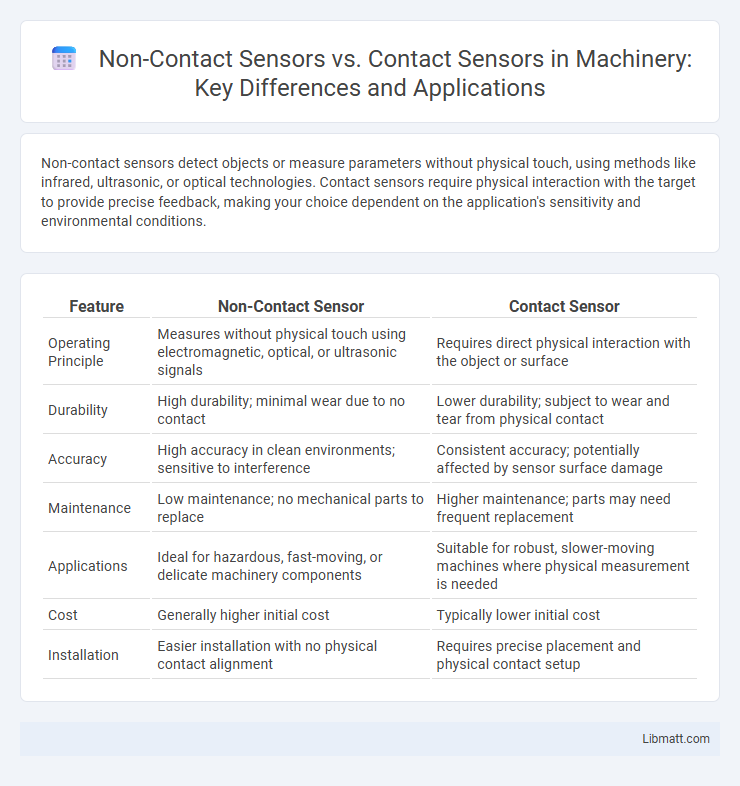

Non-contact sensors detect objects or measure parameters without physical touch, using methods like infrared, ultrasonic, or optical technologies. Contact sensors require physical interaction with the target to provide precise feedback, making your choice dependent on the application's sensitivity and environmental conditions.

Table of Comparison

| Feature | Non-Contact Sensor | Contact Sensor |

|---|---|---|

| Operating Principle | Measures without physical touch using electromagnetic, optical, or ultrasonic signals | Requires direct physical interaction with the object or surface |

| Durability | High durability; minimal wear due to no contact | Lower durability; subject to wear and tear from physical contact |

| Accuracy | High accuracy in clean environments; sensitive to interference | Consistent accuracy; potentially affected by sensor surface damage |

| Maintenance | Low maintenance; no mechanical parts to replace | Higher maintenance; parts may need frequent replacement |

| Applications | Ideal for hazardous, fast-moving, or delicate machinery components | Suitable for robust, slower-moving machines where physical measurement is needed |

| Cost | Generally higher initial cost | Typically lower initial cost |

| Installation | Easier installation with no physical contact alignment | Requires precise placement and physical contact setup |

Introduction to Non-Contact and Contact Sensors

Non-contact sensors measure physical properties without direct physical interaction, using technologies such as ultrasonic, infrared, and capacitive sensing for applications requiring cleanliness or hazardous environment access. Contact sensors rely on direct physical touch to detect parameters like pressure, position, or temperature using devices such as strain gauges, thermocouples, and switches, delivering precise, real-time data in controlled settings. Selecting between non-contact and contact sensors depends on factors including environmental conditions, measurement accuracy, and the nature of the target object.

Fundamental Differences Between Non-Contact and Contact Sensors

Non-contact sensors detect objects or measure parameters without physical touch, using technologies like infrared, ultrasonic, or laser, providing advantages in wear-free operation and suitability for hazardous environments. Contact sensors require physical interaction with the target, such as pressure sensors or tactile switches, offering direct and often more precise measurements but with potential wear and maintenance concerns. The fundamental difference lies in the method of detection--non-contact sensors rely on emitted signals and their reflections, while contact sensors depend on mechanical or electrical changes upon contact.

How Non-Contact Sensors Work

Non-contact sensors operate by detecting changes in physical properties such as electromagnetic fields, light, or sound waves without direct physical contact with the object. These sensors use technologies like infrared, ultrasonic, capacitive, or photoelectric detection to measure distance, presence, or movement accurately and rapidly. This eliminates wear and tear, reduces contamination risk, and enables measurements in hazardous or hard-to-reach environments.

How Contact Sensors Operate

Contact sensors operate by physically interacting with the target object, detecting changes in pressure, position, or force through direct touch. Common types include limit switches, strain gauges, and tactile sensors, which provide precise and reliable data for applications requiring exact location or force measurement. These sensors convert mechanical movements or deformations into electrical signals, enabling accurate monitoring and control in industrial automation, robotics, and safety systems.

Advantages of Non-Contact Sensors

Non-contact sensors offer significant advantages, including the ability to measure objects without physical interference or wear, ensuring longer sensor lifespan and reduced maintenance costs. They provide high precision and fast response times, which are crucial for applications requiring real-time monitoring and safety in hazardous environments. Your system benefits from non-contact sensors by enabling accurate detection and measurement in situations where direct contact is impractical or could damage the sensor or target.

Benefits of Contact Sensors

Contact sensors provide precise and reliable measurements by physically interacting with the target surface, ensuring high accuracy in applications requiring direct measurement. These sensors are generally more cost-effective and easier to implement in environments where close proximity is possible, delivering consistent performance even in challenging conditions. Your choice of contact sensors supports robust data collection crucial for industrial machinery, automation systems, and quality control processes.

Typical Applications of Non-Contact Sensors

Non-contact sensors are widely used in applications requiring precise measurement without physical interaction, such as in industrial automation for detecting object presence, speed, or position on assembly lines. They excel in environments where contamination, wear, or damage to the sensor or target must be avoided, including robotics, automotive systems, and medical devices. Your choice of a non-contact sensor can enhance performance in quality control, safety systems, and material handling by providing accurate and reliable data without mechanical interference.

Common Uses for Contact Sensors

Contact sensors are commonly used in security systems to detect the opening or closing of doors and windows, providing real-time alerts for unauthorized access. They are also widely implemented in industrial automation to monitor machine safety by sensing physical interactions or position changes on equipment. Your choice of contact sensors ensures reliable operation in environments where direct physical interaction is necessary for accurate detection.

Key Factors in Choosing Between Non-Contact and Contact Sensors

Key factors in choosing between non-contact and contact sensors include accuracy, environmental conditions, and application requirements. Non-contact sensors offer benefits in applications where hygiene, high temperatures, or moving objects make physical contact impractical, while contact sensors often provide more precise measurements for static or stable surfaces. Your decision should consider sensor durability, response time, and maintenance needs to ensure optimal performance in your specific use case.

Future Trends in Sensor Technology

Non-contact sensors are increasingly dominating the future of sensor technology due to their ability to provide accurate measurements without physical wear or contamination, making them ideal for industries like healthcare and manufacturing automation. Advances in optical, ultrasonic, and radar sensors are enhancing non-contact sensing capabilities, offering higher precision and real-time data integration with IoT systems. Contact sensors, while still relevant in specific applications requiring direct measurement, are being enhanced by flexible materials and wireless connectivity to improve durability and ease of installation.

Non-contact sensor vs contact sensor Infographic

libmatt.com

libmatt.com