Precision casting and investment casting both involve creating detailed metal parts by pouring molten metal into molds, but precision casting typically emphasizes tighter dimensional tolerances and smoother surface finishes. Your choice depends on the complexity of the design and the level of accuracy required for the final product.

Table of Comparison

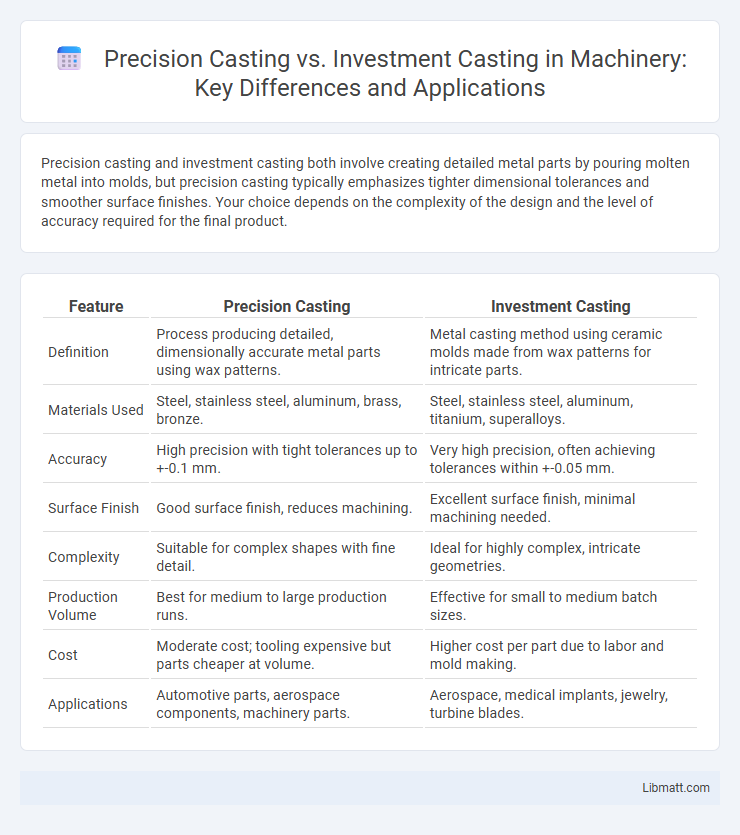

| Feature | Precision Casting | Investment Casting |

|---|---|---|

| Definition | Process producing detailed, dimensionally accurate metal parts using wax patterns. | Metal casting method using ceramic molds made from wax patterns for intricate parts. |

| Materials Used | Steel, stainless steel, aluminum, brass, bronze. | Steel, stainless steel, aluminum, titanium, superalloys. |

| Accuracy | High precision with tight tolerances up to +-0.1 mm. | Very high precision, often achieving tolerances within +-0.05 mm. |

| Surface Finish | Good surface finish, reduces machining. | Excellent surface finish, minimal machining needed. |

| Complexity | Suitable for complex shapes with fine detail. | Ideal for highly complex, intricate geometries. |

| Production Volume | Best for medium to large production runs. | Effective for small to medium batch sizes. |

| Cost | Moderate cost; tooling expensive but parts cheaper at volume. | Higher cost per part due to labor and mold making. |

| Applications | Automotive parts, aerospace components, machinery parts. | Aerospace, medical implants, jewelry, turbine blades. |

Overview: Precision Casting vs Investment Casting

Precision casting and investment casting both involve creating detailed metal components through mold-making processes, with investment casting specifically referring to the lost-wax method. Precision casting emphasizes high dimensional accuracy and smooth surface finishes, making it ideal for intricate parts in aerospace and medical industries. Understanding these nuances helps you choose the right casting technique for complex, high-tolerance applications.

Definitions and Key Differences

Precision casting and investment casting are advanced metal casting processes used to create intricate and high-quality components with excellent surface finishes and tight tolerances. Precision casting refers to the general category of casting methods designed for dimensional accuracy, while investment casting specifically involves creating a ceramic mold from a wax pattern to produce detailed and complex shapes. Understanding the key differences helps you select the right process for applications requiring superior precision and fine detail in metal parts.

Historical Development of Both Methods

Precision casting, historically known as lost wax casting, dates back to ancient civilizations such as Mesopotamia around 3500 BCE, evolving through techniques refined by the Egyptians and Greeks. Investment casting, a modern adaptation of precision casting, emerged prominently in the mid-20th century with advancements in ceramic molds and wax pattern technologies, enhancing dimensional accuracy and surface finish. Both methods share a foundational process but diverge in technological innovations and applications shaped by industrial demands and material science progress.

Materials Used in Precision and Investment Casting

Precision casting primarily utilizes metals such as stainless steel, aluminum, brass, and bronze, known for their high strength and corrosion resistance. Investment casting materials often include alloys like nickel, cobalt, and various superalloys, chosen for their excellent mechanical properties and high-temperature performance. Both methods support a wide range of metals, but investment casting typically accommodates more complex materials for aerospace and medical applications.

Process Steps: Precision Casting Explained

Precision casting involves creating a wax model that is coated with a refractory ceramic material to form a mold, which is then heated to remove the wax and hardened for metal pouring. This process ensures high accuracy and intricate detail, making it ideal for complex components in aerospace and automotive industries. Your choice of precision casting can significantly enhance the dimensional consistency and surface finish of metal parts.

Process Steps: Investment Casting Explained

Investment casting involves creating a wax pattern, coating it with a ceramic shell, and then melting out the wax to form a mold cavity for molten metal. This process steps include pattern assembly, shell building through repeated dipping and stuccoing, dewaxing in an autoclave or kiln, and finally pouring molten metal into the ceramic mold. Precision casting, often synonymous with investment casting, excels in producing complex, high-precision components with excellent surface finish and dimensional accuracy through these detailed steps.

Advantages of Precision Casting

Precision casting offers superior dimensional accuracy and surface finish, reducing the need for secondary machining and saving manufacturing time. The process enables the production of complex geometries with minimal material waste, enhancing cost efficiency for intricate parts. Your projects benefit from consistent quality and high repeatability, making precision casting ideal for aerospace, automotive, and medical components.

Advantages of Investment Casting

Investment casting offers superior dimensional accuracy and intricate detail reproduction compared to precision casting, reducing the need for extensive machining. Its ability to produce complex geometries and thin walls enhances material efficiency and reduces waste. Your projects benefit from improved surface finish quality and a wider range of compatible alloys, leading to enhanced performance and durability.

Applications and Industries

Precision casting and investment casting both offer high accuracy and intricate detail, making them essential in aerospace, automotive, medical, and jewelry industries. Precision casting excels in manufacturing complex metal parts for aircraft engines and medical implants, while investment casting is preferred for producing high-quality components like turbine blades, sculptures, and intricate jewelry. Your choice depends on the specific application requirements, such as material type, dimensional precision, and production volume.

Choosing the Right Casting Method

Precision casting and investment casting both offer high accuracy and fine detail, but selecting the right method depends on factors like material complexity, production volume, and surface finish requirements. Precision casting is ideal for smaller, intricate parts needing tight tolerances, commonly used in aerospace and medical industries. Investment casting excels in producing complex shapes with excellent surface quality and is preferred for medium to large batch manufacturing in automotive and industrial applications.

Precision casting vs investment casting Infographic

libmatt.com

libmatt.com