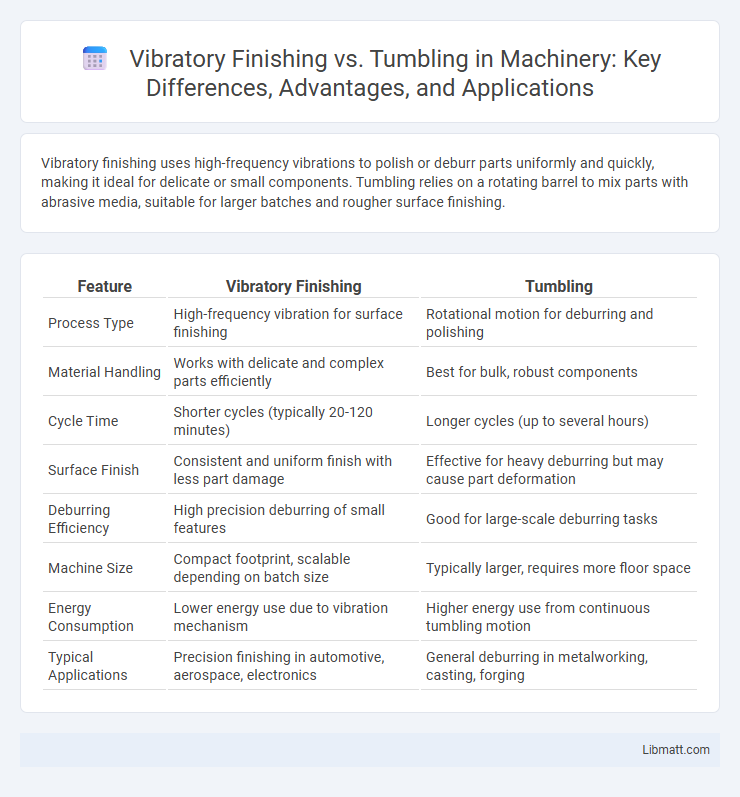

Vibratory finishing uses high-frequency vibrations to polish or deburr parts uniformly and quickly, making it ideal for delicate or small components. Tumbling relies on a rotating barrel to mix parts with abrasive media, suitable for larger batches and rougher surface finishing.

Table of Comparison

| Feature | Vibratory Finishing | Tumbling |

|---|---|---|

| Process Type | High-frequency vibration for surface finishing | Rotational motion for deburring and polishing |

| Material Handling | Works with delicate and complex parts efficiently | Best for bulk, robust components |

| Cycle Time | Shorter cycles (typically 20-120 minutes) | Longer cycles (up to several hours) |

| Surface Finish | Consistent and uniform finish with less part damage | Effective for heavy deburring but may cause part deformation |

| Deburring Efficiency | High precision deburring of small features | Good for large-scale deburring tasks |

| Machine Size | Compact footprint, scalable depending on batch size | Typically larger, requires more floor space |

| Energy Consumption | Lower energy use due to vibration mechanism | Higher energy use from continuous tumbling motion |

| Typical Applications | Precision finishing in automotive, aerospace, electronics | General deburring in metalworking, casting, forging |

Introduction to Vibratory Finishing and Tumbling

Vibratory finishing and tumbling are prevalent mass finishing techniques used for deburring, polishing, and surface conditioning of metal and plastic parts. Vibratory finishing employs rapid, circular or elliptical motions to generate friction between parts and abrasive media, enabling efficient material removal and surface enhancement. Tumbling utilizes a rotating drum to create a cascading action, promoting uniform surface treatment through continuous media movement for diverse industrial applications.

How Vibratory Finishing Works

Vibratory finishing operates by placing parts in a vibrating bowl filled with abrasive media, where rapid oscillations create friction to deburr, polish, and clean surfaces efficiently. This process uses controlled vibration amplitude and frequency to ensure uniform material removal and surface enhancement without damaging delicate components. Vibratory finishing is favored for high throughput and consistent finishing in industries like automotive, aerospace, and manufacturing.

How Tumbling Works

Tumbling operates by placing parts and abrasive media into a rotating barrel or bowl that continuously turns, causing friction and impact to smooth, deburr, and polish surfaces. The rotational movement ensures uniform contact between media and parts, effectively removing sharp edges and improving surface finish. This process is widely used for batch processing small to medium-sized metal components in manufacturing.

Key Differences Between Vibratory Finishing and Tumbling

Vibratory finishing uses rapid vibrations to create a scrubbing motion that efficiently deburrs, cleans, or polishes parts, while tumbling relies on rotational movement to achieve similar results through impact and friction. The key differences include vibratory finishing's ability to handle delicate parts with minimal damage and faster processing times compared to tumbling, which excels at mass processing of bulkier components. Your choice depends on the precision required and the nature of the materials being processed, with vibratory finishing offering more customization through media selection and machine settings.

Material Compatibility: Metals, Plastics, and Ceramics

Vibratory finishing is highly effective for metals, plastics, and ceramics, providing gentle yet consistent surface treatment that preserves material integrity and minimizes deformation. Tumbling suits robust metals well but may cause damage or excessive abrasion on softer plastics and delicate ceramics due to its aggressive motion. Selecting the appropriate method depends on the material's hardness, fragility, and desired surface finish quality.

Surface Finish Comparison

Vibratory finishing delivers a more uniform and controlled surface finish, ideal for delicate parts requiring precise edge radiusing and minimal material removal. Tumbling excels at smoothing larger batches of robust components, achieving a consistent but less refined finish due to its rotational motion and abrasive media. Your choice depends on the desired surface texture and part sensitivity, with vibratory finishing providing superior polish for fine detailing.

Cycle Time and Efficiency

Vibratory finishing typically offers shorter cycle times compared to tumbling due to its continuous vibratory motion that accelerates the polishing process and improves material removal rates. Efficiency in vibratory finishing is enhanced by uniform media agitation, which results in consistent surface finishes and reduced processing time per batch. Tumbling, while effective for bulk processing, generally requires longer cycle times and may involve more frequent media changes, impacting overall operational efficiency.

Equipment and Maintenance Requirements

Vibratory finishing equipment consists of a vibrating tub and media that gently rub against workpieces to deburr and polish surfaces, requiring regular checks for motor alignment and media wear to maintain efficiency. Tumbling employs rotating barrels filled with parts and abrasive media, demanding consistent monitoring of barrel condition, drive mechanism lubrication, and media replenishment to prevent uneven finishing. Both processes necessitate routine maintenance to ensure optimal performance, but vibratory finishing generally involves less mechanical wear compared to the tumbling method.

Cost Analysis: Vibratory Finishing vs Tumbling

Vibratory finishing typically incurs higher initial equipment costs compared to tumbling, but it offers faster cycle times and lower labor expenses, resulting in improved cost efficiency for large production volumes. Tumbling requires less costly machinery and abrasive media but often demands longer processing durations and increased maintenance, which can elevate overall operational costs. You should evaluate the balance between upfront investment and long-term expenses to determine the most cost-effective method for your specific finishing needs.

Choosing the Right Process for Your Application

Choosing between vibratory finishing and tumbling depends on the complexity and volume of your parts as well as the desired finish quality. Vibratory finishing offers precise surface conditioning with faster cycle times, making it ideal for delicate or intricate components requiring consistent results. Tumbling is more suitable for bulk processing of larger parts where aggressive material removal or deburring is needed.

Vibratory finishing vs tumbling Infographic

libmatt.com

libmatt.com