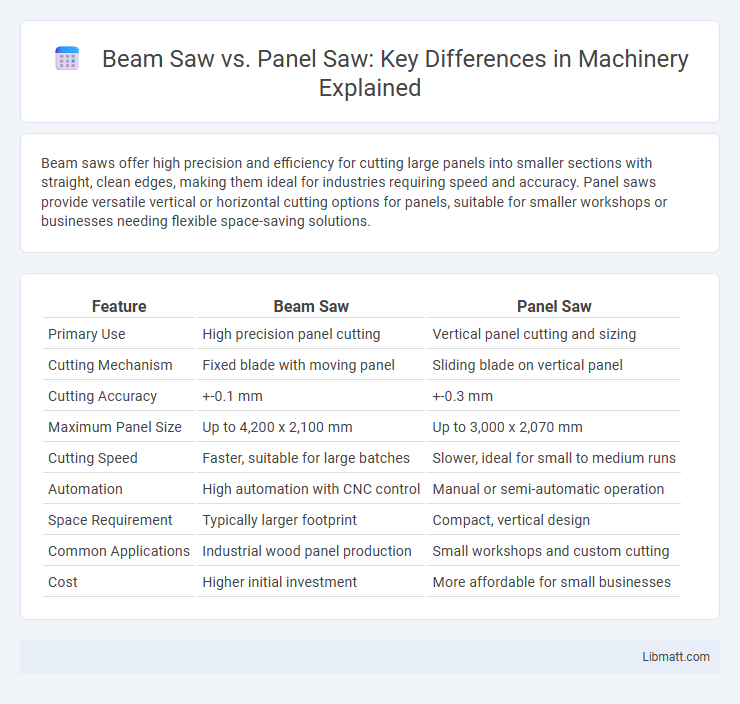

Beam saws offer high precision and efficiency for cutting large panels into smaller sections with straight, clean edges, making them ideal for industries requiring speed and accuracy. Panel saws provide versatile vertical or horizontal cutting options for panels, suitable for smaller workshops or businesses needing flexible space-saving solutions.

Table of Comparison

| Feature | Beam Saw | Panel Saw |

|---|---|---|

| Primary Use | High precision panel cutting | Vertical panel cutting and sizing |

| Cutting Mechanism | Fixed blade with moving panel | Sliding blade on vertical panel |

| Cutting Accuracy | +-0.1 mm | +-0.3 mm |

| Maximum Panel Size | Up to 4,200 x 2,100 mm | Up to 3,000 x 2,070 mm |

| Cutting Speed | Faster, suitable for large batches | Slower, ideal for small to medium runs |

| Automation | High automation with CNC control | Manual or semi-automatic operation |

| Space Requirement | Typically larger footprint | Compact, vertical design |

| Common Applications | Industrial wood panel production | Small workshops and custom cutting |

| Cost | Higher initial investment | More affordable for small businesses |

Introduction to Beam Saws and Panel Saws

Beam saws utilize a tensioned blade guided along a rigid beam to deliver precise and efficient cutting of large wood or composite panels, ideal for mass production in woodworking and furniture manufacturing. Panel saws operate with a vertically or horizontally mounted circular blade, enabling versatile cutting of sheet materials with an emphasis on space-saving in smaller workshops. Both machines optimize accuracy and productivity in panel processing, but beam saws generally provide superior speed and repeatability for industrial applications.

Key Differences Between Beam Saws and Panel Saws

Beam saws feature a fixed, straight blade that moves along a beam to ensure precise, straight cuts ideal for sheet goods, while panel saws use a stationary blade with a movable table or vice versa, optimizing efficiency for larger panels. Beam saws typically offer higher cutting speed and accuracy for repetitive cuts, whereas panel saws are more versatile for varied panel sizes and thicknesses. The choice between beam saw and panel saw depends on production volume, material type, and required cut precision.

Precision and Cutting Accuracy Comparison

Beam saws provide superior cutting accuracy with precise electronic positioning systems and rigid beams that minimize vibrations, making them ideal for detailed cabinetry and furniture manufacturing. Panel saws offer good precision for straight cuts but typically lack the advanced control systems of beam saws, resulting in slightly less accuracy on complex cuts. Overall, beam saws deliver higher precision and repeatability, crucial for industries demanding exact tolerances and high-quality finishes.

Material Types and Thickness Capabilities

Beam saws excel at handling a wide range of material types, including wood, plastics, and composite panels, with thickness capabilities typically up to 2 inches, making them ideal for heavy-duty cutting tasks. Panel saws are designed primarily for cutting large sheet materials like plywood, MDF, and laminated panels, often accommodating thicknesses up to 1.5 inches. Your choice between a beam saw and a panel saw depends on the specific material types and thickness requirements of your cutting projects.

Productivity and Workflow Efficiency

Beam saws enhance productivity by enabling precise, high-speed cutting of large panels with minimal setup time, reducing material waste and operator fatigue. Panel saws offer flexibility in cutting various panel sizes but generally require more manual handling, which can slow workflow and increase labor costs. Integrating beam saws into production lines significantly streamlines workflow efficiency by automating repetitive cuts and maintaining consistent quality throughout high-volume manufacturing.

Ease of Use and Operator Skill Requirements

Beam saws offer greater ease of use with automated controls and preset cutting programs, reducing the need for advanced operator skills. Panel saws typically demand higher manual dexterity and experience for precise cuts, making them less beginner-friendly. Choosing the right saw depends on your skill level and the complexity of the cutting tasks involved.

Maintenance and Durability Considerations

Beam saws generally require more maintenance due to their complex moving parts and laser alignment systems, but they offer higher precision and durability for intensive cutting tasks. Panel saws feature simpler mechanisms with fewer components, resulting in lower maintenance demands and longer-lasting performance for less frequent use. Your choice depends on balancing operational intensity with maintenance capacity to ensure optimal durability and efficiency.

Cost Analysis and Investment Value

Beam saws typically involve higher upfront investment costs compared to panel saws due to advanced automation features and precision cutting capabilities. Panel saws offer lower initial purchase prices and reduced maintenance expenses, making them cost-effective for smaller-scale operations. Evaluating long-term investment value depends on production volume, where beam saws provide greater efficiency and material optimization, potentially yielding higher returns in high-demand manufacturing environments.

Best Applications for Beam Saws vs Panel Saws

Beam saws excel in high-volume production environments where precision and speed are critical, often used for cutting large sheets of wood, plastic, or composite materials into smaller, uniform panels. Panel saws are ideal for workshops or smaller-scale operations requiring versatility and space-saving design, designed for vertical or horizontal cuts on sheet materials with moderate throughput needs. Choosing between the two depends on production scale, material types, and workflow layout requirements.

Choosing the Right Saw for Your Workshop

Beam saws provide precise, straight cuts ideal for high-volume production and handling large sheet materials efficiently, making them suitable for workshops focusing on cabinetry or furniture manufacturing. Panel saws, with their vertical or horizontal designs, optimize space and offer ease of use for smaller operations requiring versatile cutting of panels and boards. Prioritizing your workshop's material dimensions, production scale, and space constraints ensures selecting the most efficient saw type for enhanced workflow and accuracy.

Beam saw vs panel saw Infographic

libmatt.com

libmatt.com