Multi-spindle lathes offer increased productivity by simultaneously machining multiple parts, making them ideal for high-volume production, whereas single-spindle lathes provide greater flexibility and precision for custom or smaller batch work. Choosing between the two depends on Your specific manufacturing needs, balancing speed with versatility.

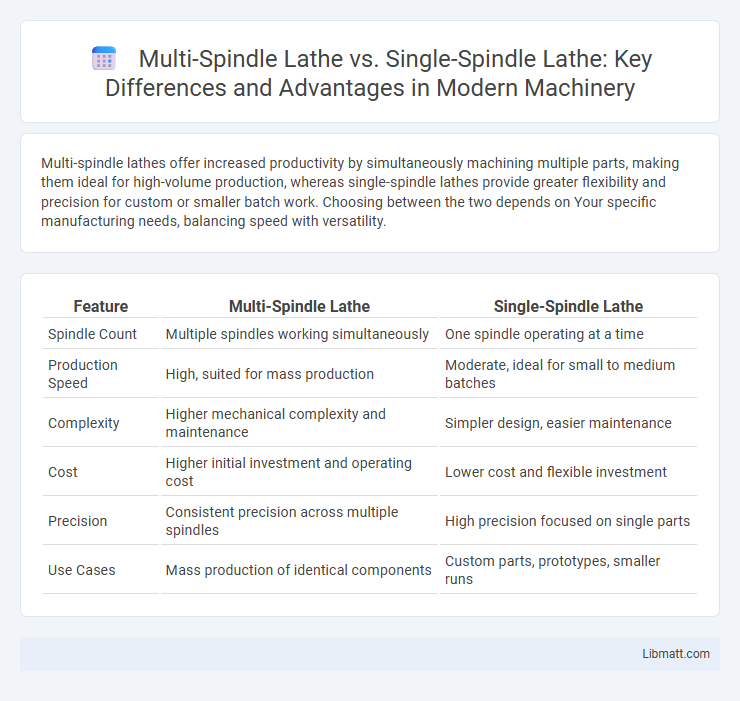

Table of Comparison

| Feature | Multi-Spindle Lathe | Single-Spindle Lathe |

|---|---|---|

| Spindle Count | Multiple spindles working simultaneously | One spindle operating at a time |

| Production Speed | High, suited for mass production | Moderate, ideal for small to medium batches |

| Complexity | Higher mechanical complexity and maintenance | Simpler design, easier maintenance |

| Cost | Higher initial investment and operating cost | Lower cost and flexible investment |

| Precision | Consistent precision across multiple spindles | High precision focused on single parts |

| Use Cases | Mass production of identical components | Custom parts, prototypes, smaller runs |

Introduction to Lathes: Multi-Spindle vs Single-Spindle

Single-spindle lathes operate with one tool spindle, making them ideal for flexible, low to medium volume production with simpler setups. Multi-spindle lathes feature multiple spindles arranged in a cluster, enabling simultaneous machining of several parts, significantly increasing production speed and efficiency for high-volume tasks. Understanding the differences in spindle count and operational capacity helps you select the best lathe type to optimize manufacturing workflows and productivity.

Understanding Single-Spindle Lathes

Single-spindle lathes feature a single rotating spindle that holds and turns the workpiece, making them ideal for precise, low to medium volume production tasks. These machines offer versatility for various turning operations but may have slower cycle times compared to multi-spindle lathes. Your choice of a single-spindle lathe ensures easier setup and flexibility for custom or complex parts manufacturing.

Features of Multi-Spindle Lathes

Multi-spindle lathes feature multiple spindles arranged in a fixed pattern, allowing simultaneous machining of several workpieces, which significantly increases production efficiency compared to single-spindle lathes. These machines often include synchronized spindle rotation and automatic tool changers, enabling complex and high-volume operations with minimal downtime. Your manufacturing process benefits from improved precision and faster cycle times when using multi-spindle lathes for repetitive tasks.

Key Differences Between Multi-Spindle and Single-Spindle Lathes

Multi-spindle lathes feature multiple spindles that operate concurrently, enabling higher production rates and consistent machining of complex parts, whereas single-spindle lathes use one spindle, suitable for smaller runs or simpler components. Multi-spindle machines excel in mass production with reduced cycle times, while single-spindle lathes offer greater flexibility for customized or intricate workpieces. Your choice depends on the volume and complexity of parts, balancing speed with precision and versatility.

Productivity Comparison: Multi-Spindle vs Single-Spindle

Multi-spindle lathes significantly boost productivity by simultaneously machining multiple parts, reducing cycle time and increasing output compared to single-spindle lathes, which handle one part per cycle. Your choice impacts manufacturing efficiency, with multi-spindle machines ideal for high-volume production due to parallel processing capabilities. Single-spindle lathes offer flexibility and simpler operation, but lower throughput, making them suitable for small batches or complex parts.

Application Suitability: Which Lathe for Which Job?

Multi-spindle lathes excel in high-volume production environments, efficiently machining multiple parts simultaneously to reduce cycle times and increase throughput. Single-spindle lathes offer greater flexibility and precision, making them ideal for custom, complex, or low-volume jobs where individual attention to detail is crucial. Choosing between multi-spindle and single-spindle lathes depends on project scale, complexity, and required production speed.

Cost Analysis: Initial Investment and Operating Expenses

Multi-spindle lathes have a higher initial investment compared to single-spindle lathes due to their complex design and increased production capacity. Operating expenses for multi-spindle lathes tend to be lower on a per-part basis because they reduce cycle time and increase efficiency in high-volume manufacturing. Single-spindle lathes usually incur lower maintenance costs but may lead to higher labor costs and longer production cycles when handling large batch sizes.

Precision and Quality Outcomes

Multi-spindle lathes deliver higher precision and consistent quality outcomes by simultaneously machining multiple parts, reducing variability caused by tool changes and repositioning. Single-spindle lathes may offer flexibility but often face limitations in maintaining uniform precision across large production runs. You should choose a multi-spindle lathe when high-volume manufacturing demands tight tolerances and superior surface finishes.

Maintenance Requirements and Longevity

Multi-spindle lathes generally demand more frequent and specialized maintenance due to their complex mechanisms, which can increase downtime compared to single-spindle lathes. Single-spindle lathes feature simpler designs, resulting in easier upkeep and potentially longer operational lifespan when properly maintained. Understanding your machining needs helps determine whether the balance of maintenance effort and machine longevity aligns with your production goals.

Choosing the Right Lathe for Your Manufacturing Needs

Selecting between a multi-spindle lathe and a single-spindle lathe depends on your production volume and precision requirements. Multi-spindle lathes offer higher throughput by machining multiple parts simultaneously, ideal for large-scale manufacturing with complex components. Single-spindle lathes provide greater flexibility and precision for custom or low-volume work, making them suitable for specialized machining tasks.

Multi-spindle lathe vs single-spindle lathe Infographic

libmatt.com

libmatt.com