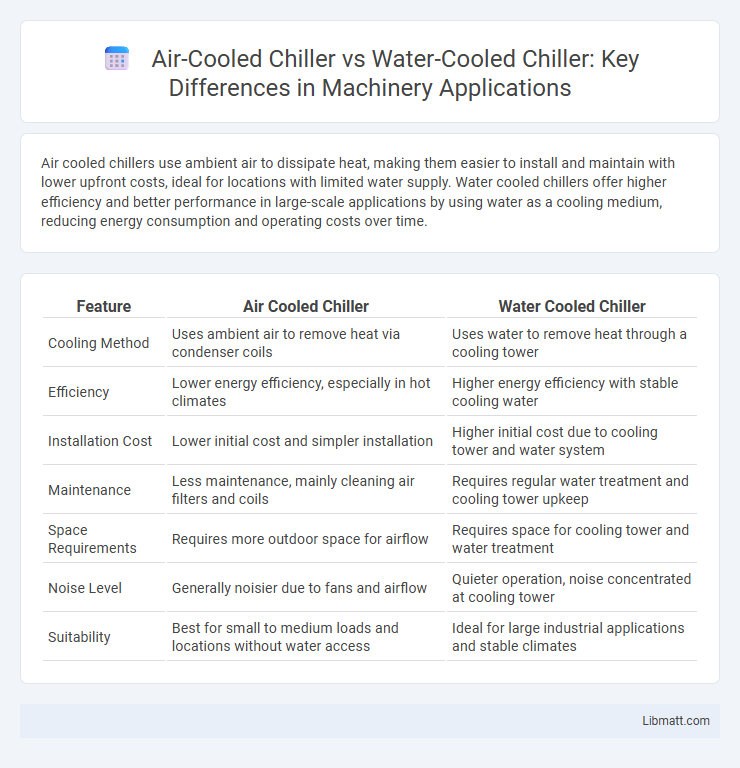

Air cooled chillers use ambient air to dissipate heat, making them easier to install and maintain with lower upfront costs, ideal for locations with limited water supply. Water cooled chillers offer higher efficiency and better performance in large-scale applications by using water as a cooling medium, reducing energy consumption and operating costs over time.

Table of Comparison

| Feature | Air Cooled Chiller | Water Cooled Chiller |

|---|---|---|

| Cooling Method | Uses ambient air to remove heat via condenser coils | Uses water to remove heat through a cooling tower |

| Efficiency | Lower energy efficiency, especially in hot climates | Higher energy efficiency with stable cooling water |

| Installation Cost | Lower initial cost and simpler installation | Higher initial cost due to cooling tower and water system |

| Maintenance | Less maintenance, mainly cleaning air filters and coils | Requires regular water treatment and cooling tower upkeep |

| Space Requirements | Requires more outdoor space for airflow | Requires space for cooling tower and water treatment |

| Noise Level | Generally noisier due to fans and airflow | Quieter operation, noise concentrated at cooling tower |

| Suitability | Best for small to medium loads and locations without water access | Ideal for large industrial applications and stable climates |

Introduction to Air Cooled vs Water Cooled Chillers

Air cooled chillers use ambient air to dissipate heat through finned coils and fans, making them ideal for locations with limited water availability and easier maintenance requirements. Water cooled chillers rely on a cooling tower and water circulation to reject heat, offering higher energy efficiency and better performance in large-scale HVAC applications. Choosing between air cooled and water cooled chillers depends on factors like installation space, climate conditions, operational costs, and cooling capacity needs.

How Air Cooled Chillers Work

Air cooled chillers operate by using ambient air to dissipate heat from the refrigerant through condenser coils equipped with fans, eliminating the need for a cooling tower or external water source. The refrigerant absorbs heat from your building or process water, then circulates to the air cooled condenser where fans blow air over the coils, releasing heat to the atmosphere. This system provides efficient cooling in locations where water availability or water treatment infrastructure is limited.

How Water Cooled Chillers Operate

Water cooled chillers operate by circulating cold water through a closed-loop system, where heat is absorbed from the building's air or equipment and transferred to the water. This heated water is then pumped to a cooling tower, where the heat is expelled into the atmosphere through evaporative cooling, allowing the water to cool down before recirculating back to the chiller. The efficiency of water cooled chillers depends on factors like condenser water temperature, cooling tower performance, and maintenance practices, making them ideal for large-scale HVAC systems with access to water resources.

Key Differences Between Air Cooled and Water Cooled Chillers

Air cooled chillers use ambient air to dissipate heat through finned coils and fans, making them ideal for outdoor installations with limited water availability. Water cooled chillers rely on water circulation, typically via cooling towers, providing higher efficiency and better performance in large-scale industrial or commercial applications. Your choice depends on factors like installation space, operational costs, and environmental conditions, as water cooled systems generally offer lower energy consumption but require more maintenance.

Energy Efficiency Comparison

Water-cooled chillers generally offer higher energy efficiency than air-cooled chillers due to their superior heat transfer capabilities and lower condenser temperatures, resulting in reduced power consumption. Air-cooled chillers typically consume more energy, especially in warmer climates, because they rely on ambient air for heat rejection, which is less efficient than water cooling. The energy efficiency ratio (EER) and coefficient of performance (COP) of water-cooled systems are typically 10-20% higher, making them more cost-effective for large-scale or continuous cooling applications.

Installation and Maintenance Requirements

Air cooled chillers feature simpler installation processes since they do not require extensive water piping or cooling towers, reducing upfront costs and space needs. Maintenance demands for air cooled chillers typically involve regular cleaning of condenser coils and verifying airflow, whereas water cooled chillers require more complex upkeep including coolant quality monitoring, pump servicing, and cooling tower maintenance. The absence of water-related components in air cooled chillers minimizes risks associated with water leaks and corrosion, offering lower long-term maintenance burdens in certain environments.

Environmental Impact and Sustainability

Air cooled chillers generally have a lower water consumption, making them more sustainable in regions with limited water resources, while water cooled chillers often achieve higher energy efficiency and reduced greenhouse gas emissions due to better heat transfer capabilities. The use of water cooled chillers typically requires cooling towers, which can pose challenges such as water treatment and potential legionella risks. Selecting between the two depends on balancing environmental factors including water scarcity, energy consumption, and local climate conditions.

Cost Analysis: Initial and Operating Expenses

Air cooled chillers typically have lower initial costs due to simpler installation and no need for cooling towers, making them ideal for smaller facilities or limited space. Water cooled chillers, while requiring higher upfront investment for cooling towers and associated infrastructure, offer greater energy efficiency and lower operating expenses over time, especially in large-scale or continuous operation environments. Your choice between these systems should consider the balance between upfront capital and long-term operating costs to optimize overall financial performance.

Best Applications for Air Cooled Chillers

Air cooled chillers are best suited for applications where water availability is limited or water conservation is a priority, making them ideal for commercial buildings, data centers, and industrial sites in arid regions. These chillers perform efficiently in outdoor installations and areas with moderate to low cooling loads, eliminating the need for cooling towers and reducing maintenance costs. Your choice of an air cooled chiller ensures a reliable, low-maintenance cooling solution, especially in environments where simplicity and reduced water usage are critical.

Best Applications for Water Cooled Chillers

Water cooled chillers are best suited for large-scale commercial and industrial applications where efficiency and space savings are critical, such as manufacturing plants, data centers, and large office buildings. Their superior cooling efficiency and ability to operate quietly make them ideal for environments with high cooling loads and limited outdoor space for heat dissipation. You should consider water cooled chillers when your facility requires consistent, high-capacity cooling with lower energy consumption and reduced environmental impact.

Air cooled chiller vs water cooled chiller Infographic

libmatt.com

libmatt.com