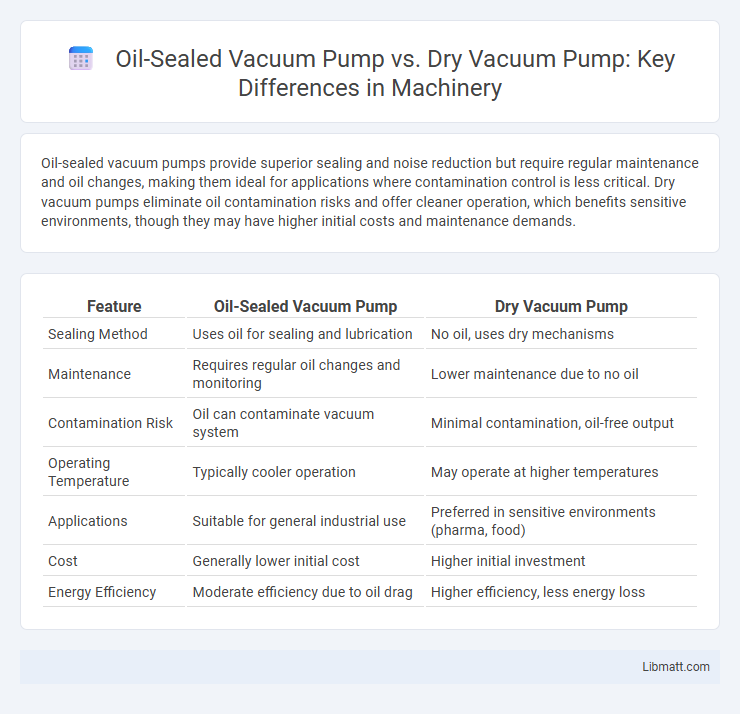

Oil-sealed vacuum pumps provide superior sealing and noise reduction but require regular maintenance and oil changes, making them ideal for applications where contamination control is less critical. Dry vacuum pumps eliminate oil contamination risks and offer cleaner operation, which benefits sensitive environments, though they may have higher initial costs and maintenance demands.

Table of Comparison

| Feature | Oil-Sealed Vacuum Pump | Dry Vacuum Pump |

|---|---|---|

| Sealing Method | Uses oil for sealing and lubrication | No oil, uses dry mechanisms |

| Maintenance | Requires regular oil changes and monitoring | Lower maintenance due to no oil |

| Contamination Risk | Oil can contaminate vacuum system | Minimal contamination, oil-free output |

| Operating Temperature | Typically cooler operation | May operate at higher temperatures |

| Applications | Suitable for general industrial use | Preferred in sensitive environments (pharma, food) |

| Cost | Generally lower initial cost | Higher initial investment |

| Energy Efficiency | Moderate efficiency due to oil drag | Higher efficiency, less energy loss |

Introduction to Vacuum Pumps

Oil-sealed vacuum pumps utilize a lubricated mechanism to create a tight seal and efficiently remove air or gas from a system, offering high ultimate vacuum and superior contamination control. Dry vacuum pumps operate without oil, reducing maintenance requirements and eliminating oil contamination, making them ideal for environmentally sensitive or clean applications. Your choice between these pumps depends on factors like desired vacuum level, maintenance preferences, and application-specific cleanliness needs.

Overview of Oil-Sealed Vacuum Pumps

Oil-sealed vacuum pumps utilize a lubricating oil film to create an airtight seal and enhance performance by reducing wear and preventing contamination. These pumps typically offer higher ultimate vacuum levels and better reliability in heavy-duty applications, making them suitable for tasks requiring continuous, high-efficiency operation. Your choice between oil-sealed and dry vacuum pumps should consider factors like maintenance frequency, environmental impact, and specific vacuum requirements.

Overview of Dry Vacuum Pumps

Dry vacuum pumps operate without lubricating oil in the vacuum chamber, eliminating contamination risks and reducing maintenance requirements. These pumps are ideal for applications demanding high purity, such as semiconductor manufacturing, pharmaceutical processing, and food packaging. Advanced designs like claw, scroll, and diaphragm pumps offer efficient, oil-free evacuation while maintaining clean, consistent vacuum levels.

Key Differences Between Oil-Sealed and Dry Vacuum Pumps

Oil-sealed vacuum pumps utilize oil as a sealing and lubricating medium, providing higher reliability and better ultimate vacuum levels, typically reaching down to 10^-3 mbar. Dry vacuum pumps operate without oil, reducing contamination risks and maintenance requirements, making them ideal for clean processes in pharmaceuticals and food industries. The choice depends on application requirements, with oil-sealed pumps favored for heavy-duty industrial use and dry pumps preferred for environmentally sensitive or contamination-free environments.

Performance and Efficiency Comparison

Oil-sealed vacuum pumps typically deliver higher ultimate vacuum levels and better sealing performance, making them suitable for applications requiring low pressure and high reliability. Dry vacuum pumps excel in energy efficiency and reduced maintenance costs since they eliminate oil contamination and the need for oil changes, enhancing overall operational sustainability. Your choice depends on balancing the superior vacuum quality of oil-sealed pumps against the environmentally friendly and cost-effective operation of dry vacuum pumps.

Maintenance Requirements and Costs

Oil-sealed vacuum pumps demand regular oil changes, filter replacements, and routine cleaning to maintain optimal performance, which can increase maintenance time and costs. Dry vacuum pumps eliminate oil contamination risks, reducing cleaning frequency and associated expenses, but may require more frequent part replacements due to wear. Your choice impacts long-term operational costs and maintenance complexity depending on the application's cleanliness and durability requirements.

Application Suitability and Industry Use

Oil-sealed vacuum pumps excel in providing high vacuum levels and are ideal for applications requiring contamination-free environments, such as semiconductor manufacturing and chemical processing. Dry vacuum pumps, offering clean operation without oil contamination, suit industries like pharmaceuticals, food packaging, and electronics where avoiding lubricant contact with the process is critical. Your choice depends on the specific industry standards and application needs, balancing factors like maintenance, vacuum performance, and contamination control.

Environmental Impact and Oil Contamination

Oil-sealed vacuum pumps generate hazardous waste through oil contamination, requiring regular oil changes and proper disposal to minimize environmental harm. Dry vacuum pumps eliminate oil usage, significantly reducing the risk of oil leaks and contamination, making them a more eco-friendly choice. Your decision to use a dry vacuum pump supports sustainable practices by preventing oil-related pollution and lowering maintenance waste.

Initial Investment and Long-Term Operating Costs

Oil-sealed vacuum pumps generally require a lower initial investment compared to dry vacuum pumps due to simpler technology and fewer specialized materials. However, the long-term operating costs are higher for oil-sealed pumps because of regular oil changes, oil disposal, and potential contamination issues. Dry vacuum pumps offer higher upfront costs but benefit from reduced maintenance, absence of oil consumption, and lower environmental compliance expenses over time.

Choosing the Right Vacuum Pump for Your Needs

Oil-sealed vacuum pumps provide reliable, high-performance vacuum levels with excellent contamination control, making them ideal for applications requiring clean and stable vacuum conditions. Dry vacuum pumps eliminate oil contamination risks and reduce maintenance costs, offering an eco-friendly solution suited for sensitive processes and industries focused on sustainability. Evaluate factors such as vacuum level requirements, maintenance preferences, contamination sensitivity, and operational costs to determine the optimal vacuum pump for your specific application.

Oil-sealed vacuum pump vs dry vacuum pump Infographic

libmatt.com

libmatt.com