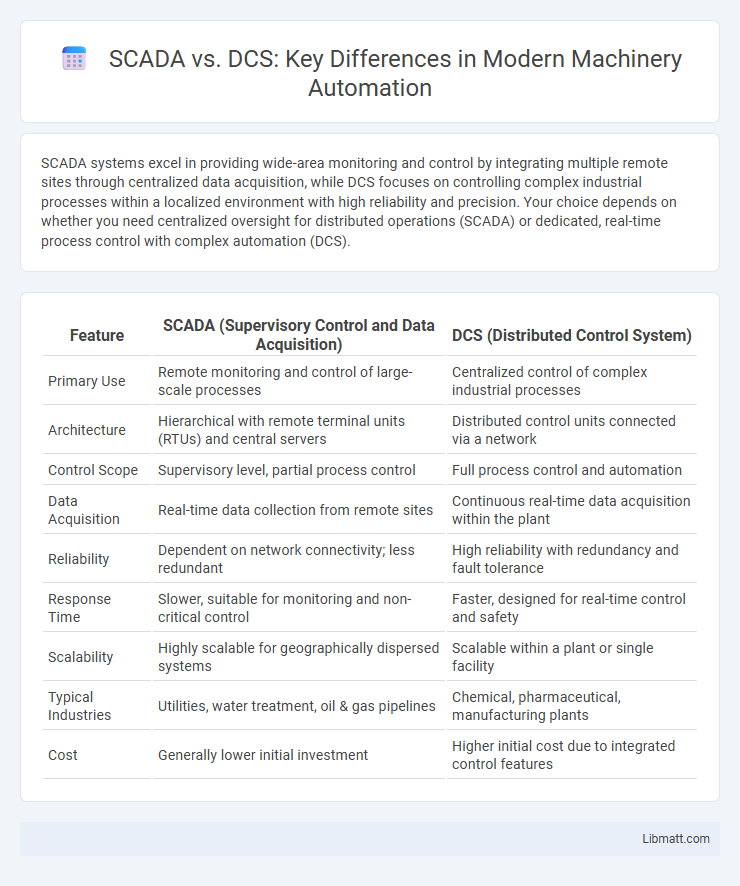

SCADA systems excel in providing wide-area monitoring and control by integrating multiple remote sites through centralized data acquisition, while DCS focuses on controlling complex industrial processes within a localized environment with high reliability and precision. Your choice depends on whether you need centralized oversight for distributed operations (SCADA) or dedicated, real-time process control with complex automation (DCS).

Table of Comparison

| Feature | SCADA (Supervisory Control and Data Acquisition) | DCS (Distributed Control System) |

|---|---|---|

| Primary Use | Remote monitoring and control of large-scale processes | Centralized control of complex industrial processes |

| Architecture | Hierarchical with remote terminal units (RTUs) and central servers | Distributed control units connected via a network |

| Control Scope | Supervisory level, partial process control | Full process control and automation |

| Data Acquisition | Real-time data collection from remote sites | Continuous real-time data acquisition within the plant |

| Reliability | Dependent on network connectivity; less redundant | High reliability with redundancy and fault tolerance |

| Response Time | Slower, suitable for monitoring and non-critical control | Faster, designed for real-time control and safety |

| Scalability | Highly scalable for geographically dispersed systems | Scalable within a plant or single facility |

| Typical Industries | Utilities, water treatment, oil & gas pipelines | Chemical, pharmaceutical, manufacturing plants |

| Cost | Generally lower initial investment | Higher initial cost due to integrated control features |

Introduction to SCADA and DCS

SCADA (Supervisory Control and Data Acquisition) systems monitor and control large-scale industrial processes, often spread across wide geographic areas, enabling real-time data acquisition and remote management. DCS (Distributed Control System) focuses on centralized control of localized processes within a plant, improving process automation and reliability through distributed controllers. Your choice between SCADA and DCS depends on the specific operational scale, control needs, and system integration requirements of your industrial setup.

Core Functions of SCADA Systems

SCADA systems primarily monitor and control industrial processes by collecting real-time data from remote devices and sensors across wide geographical areas. They provide operators with centralized control through Human-Machine Interfaces (HMI), enabling real-time visualization, alarm management, and data logging for process optimization. SCADA systems facilitate efficient supervisory control, data acquisition, and historical trend analysis, essential for industries like energy, water treatment, and manufacturing.

Core Functions of DCS Systems

DCS systems primarily manage complex industrial processes through distributed control, offering reliable automation, real-time monitoring, and precise regulatory control of multiple process variables. They excel in continuous production environments by integrating control loops and operator interfaces to optimize process efficiency and safety. Your industrial operation benefits from advanced fault tolerance and scalable architecture provided by DCS for consistent process control.

Architecture Differences Between SCADA and DCS

SCADA systems feature a distributed architecture with remote terminal units (RTUs) and programmable logic controllers (PLCs) connected to a centralized supervisory system, enabling broad geographical monitoring and control. DCS architecture centers on a hierarchy of interconnected controllers and human-machine interfaces (HMIs) within a localized environment, providing tight integration for process automation. The primary architectural distinction lies in SCADA's emphasis on wide-area data acquisition, while DCS focuses on real-time control within a single facility.

Communication Protocols in SCADA vs DCS

SCADA systems primarily use communication protocols such as Modbus, DNP3, and OPC to facilitate data exchange between remote terminal units (RTUs) and control centers, enabling efficient monitoring and control over large geographic areas. DCS relies on protocols like Profibus, Foundation Fieldbus, and HART for real-time, high-speed communication within localized industrial processes, ensuring precise and reliable automation. Understanding these protocol differences helps you select the right system based on network scale, communication speed, and interoperability requirements.

Industrial Applications of SCADA and DCS

SCADA systems excel in supervising and controlling large-scale industrial processes across diverse sectors such as water treatment, oil and gas pipelines, and power transmission networks, providing real-time data acquisition and remote monitoring capabilities. DCS is primarily deployed in complex, continuous production environments like chemical plants, refineries, and manufacturing facilities, offering integrated control of distributed processes and ensuring process stability. Your choice between SCADA and DCS depends on the specific industrial application requirements, including scale, process complexity, and control centralization.

Scalability and Flexibility Comparison

SCADA systems offer greater scalability and flexibility, making them ideal for geographically dispersed operations and easily expandable infrastructures. DCS systems provide robust control within centralized processes but are less adaptable to large-scale or remote site expansions. Your choice depends on the need for either flexible system growth or tightly integrated process control.

Data Management and Visualization

SCADA systems excel in real-time data acquisition and provide extensive visualization tools for monitoring geographically dispersed assets, offering intuitive dashboards and alarm management for operators. DCS platforms focus on centralized data management with robust process control integration, delivering detailed visualization tailored for continuous process optimization within a single facility. Your choice depends on whether you prioritize wide-area supervisory control with flexible visualization (SCADA) or integrated process control with comprehensive data handling (DCS).

Security Considerations: SCADA vs DCS

SCADA systems often face higher security risks due to their extensive network connectivity and remote access capabilities, making them more vulnerable to cyberattacks. DCS tends to offer enhanced security through centralized control and limited external exposure, reducing potential attack surfaces. Understanding these security considerations is crucial for optimizing Your industrial control system's protection against threats.

Choosing the Right System for Your Operation

Selecting the appropriate control system depends on the scale and complexity of your operation, with SCADA systems excelling in large-scale, geographically dispersed processes and DCS being ideal for integrated, localized process control. SCADA offers superior remote monitoring and flexibility, while DCS provides robust, real-time control with higher reliability for continuous production environments. Evaluate factors such as system architecture, data acquisition needs, and control precision to ensure optimal performance and efficiency.

SCADA vs DCS Infographic

libmatt.com

libmatt.com