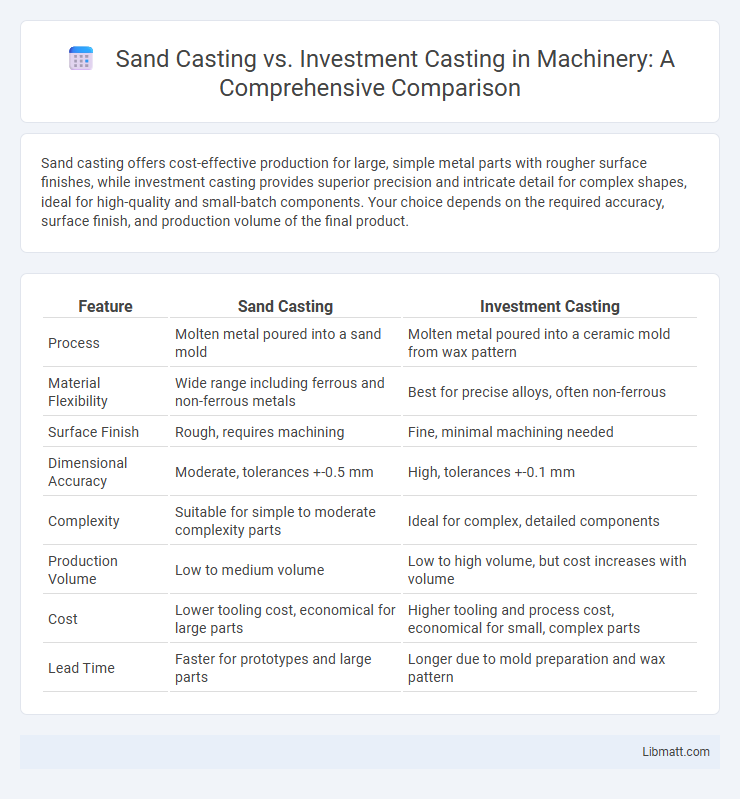

Sand casting offers cost-effective production for large, simple metal parts with rougher surface finishes, while investment casting provides superior precision and intricate detail for complex shapes, ideal for high-quality and small-batch components. Your choice depends on the required accuracy, surface finish, and production volume of the final product.

Table of Comparison

| Feature | Sand Casting | Investment Casting |

|---|---|---|

| Process | Molten metal poured into a sand mold | Molten metal poured into a ceramic mold from wax pattern |

| Material Flexibility | Wide range including ferrous and non-ferrous metals | Best for precise alloys, often non-ferrous |

| Surface Finish | Rough, requires machining | Fine, minimal machining needed |

| Dimensional Accuracy | Moderate, tolerances +-0.5 mm | High, tolerances +-0.1 mm |

| Complexity | Suitable for simple to moderate complexity parts | Ideal for complex, detailed components |

| Production Volume | Low to medium volume | Low to high volume, but cost increases with volume |

| Cost | Lower tooling cost, economical for large parts | Higher tooling and process cost, economical for small, complex parts |

| Lead Time | Faster for prototypes and large parts | Longer due to mold preparation and wax pattern |

Introduction to Sand Casting and Investment Casting

Sand casting utilizes a sand mold to create complex metal parts, offering cost-effective production for large components with moderate precision. Investment casting, also known as lost-wax casting, involves creating a ceramic mold from a wax pattern, delivering high accuracy and intricate detail for smaller, high-quality parts. Understanding these processes helps you select the ideal method based on part complexity, surface finish, and production volume.

Overview of the Sand Casting Process

Sand casting involves creating a mold from a sand mixture, where molten metal is poured to form the desired shape. This process allows for large, complex parts with good surface finish and dimensional accuracy. Your choice between sand casting and investment casting depends on factors like production volume, detail requirements, and material properties.

Overview of the Investment Casting Process

Investment casting, also known as lost-wax casting, involves creating a precise wax pattern coated with a refractory ceramic material to form a mold, which is then heated to remove the wax and hardened for molten metal pouring. This process delivers intricate detail and smooth surface finishes, outperforming sand casting in accuracy and complexity. You benefit from tighter tolerances and reduced machining needs, making investment casting ideal for high-precision components in aerospace, automotive, and medical industries.

Material Compatibility and Selection

Sand casting offers versatility with a wide range of metals including steel, iron, aluminum, and bronze, making it suitable for larger parts and high-temperature alloys. Investment casting excels in handling complex geometries and fine details, particularly with stainless steel, nickel alloys, and superalloys, ideal for precision components. Your choice between sand casting and investment casting depends on the specific material properties and the complexity required for your application.

Surface Finish and Dimensional Accuracy

Investment casting offers superior surface finish with a smoother texture and minimal parting lines, resulting in reduced machining requirements compared to sand casting. Dimensional accuracy in investment casting typically ranges within +-0.005 inches, enabling the production of intricate and precise components, whereas sand casting generally allows tolerances around +-0.030 inches, suitable for larger, less detailed parts. The finer mold materials used in investment casting contribute to higher resolution details and tighter tolerances, making it ideal for applications demanding high precision and excellent surface quality.

Cost and Production Efficiency Comparison

Sand casting offers a lower initial cost and faster setup time, making it more cost-effective for small to medium production runs, while investment casting incurs higher tooling expenses but delivers superior precision and minimal machining, enhancing production efficiency for complex, high-volume parts. Investment casting's ability to produce near-net-shape components reduces material waste and post-processing costs, offsetting its higher upfront investment over time. Sand casting's versatility suits large, low-complexity parts, but investment casting is preferred for intricate geometries requiring tight tolerances and consistent repeatability.

Design Complexity and Flexibility

Sand casting offers greater design flexibility for large, simple shapes but struggles with fine detail due to its coarse mold material. Investment casting excels in producing complex, intricate geometries with high dimensional accuracy and smooth surface finishes. This precision makes investment casting ideal for components requiring tight tolerances and elaborate designs that sand casting cannot achieve efficiently.

Application and Industry Suitability

Sand casting is ideal for producing large, complex metal parts with moderate precision, commonly used in industries such as automotive, agriculture, and construction for components like engine blocks and pump housings. Investment casting offers superior accuracy and surface finish, making it suitable for aerospace, medical, and jewelry applications where intricate designs and tight tolerances are crucial. Your choice depends on the required detail, production volume, and industry-specific standards.

Environmental Impact and Sustainability

Sand casting generates significant waste due to its expendable mold materials, often leading to landfill disposal and higher energy consumption during sand reclamation processes. Investment casting, although more energy-intensive during wax pattern production, produces minimal waste as molds are reusable or recyclable, enhancing sustainability efforts. Your choice between these methods can reduce environmental impact by prioritizing investment casting for precision and waste reduction or sand casting when minimizing initial carbon footprint is less critical.

Choosing the Right Casting Method for Your Project

Sand casting offers cost-effective production with versatility in size and material, ideal for large or simple parts. Investment casting delivers superior surface finish and intricate detail, perfect for complex shapes requiring tight tolerances. Understanding your project's requirements, including budget, detail precision, and production volume, helps you select the casting method that maximizes efficiency and quality.

Sand casting vs investment casting Infographic

libmatt.com

libmatt.com