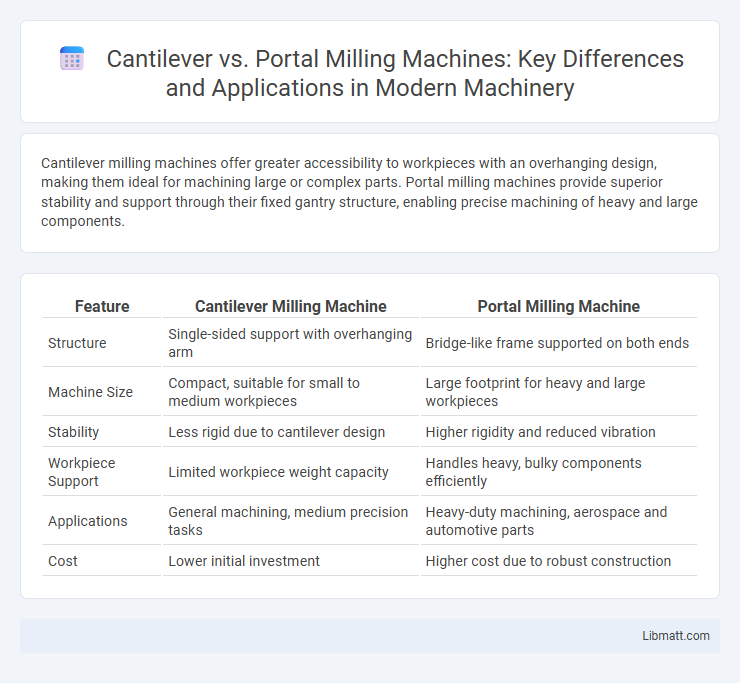

Cantilever milling machines offer greater accessibility to workpieces with an overhanging design, making them ideal for machining large or complex parts. Portal milling machines provide superior stability and support through their fixed gantry structure, enabling precise machining of heavy and large components.

Table of Comparison

| Feature | Cantilever Milling Machine | Portal Milling Machine |

|---|---|---|

| Structure | Single-sided support with overhanging arm | Bridge-like frame supported on both ends |

| Machine Size | Compact, suitable for small to medium workpieces | Large footprint for heavy and large workpieces |

| Stability | Less rigid due to cantilever design | Higher rigidity and reduced vibration |

| Workpiece Support | Limited workpiece weight capacity | Handles heavy, bulky components efficiently |

| Applications | General machining, medium precision tasks | Heavy-duty machining, aerospace and automotive parts |

| Cost | Lower initial investment | Higher cost due to robust construction |

Introduction to Cantilever and Portal Milling Machines

Cantilever milling machines feature a single-column structure with the worktable supported on one side, allowing enhanced accessibility and flexibility for machining large, heavy parts. Portal milling machines have a robust framework with a bridge-like structure spanning over the worktable, providing superior rigidity and precision for heavy-duty milling of large components. Both types are widely used in industries requiring high accuracy and stability, such as aerospace, automotive, and mold manufacturing.

Overview of Cantilever Milling Machines

Cantilever milling machines feature a distinctive design where the worktable is supported on one side by a cantilevered arm, allowing unobstructed access to the workpiece and enhanced flexibility in machining complex parts. This design reduces the machine's footprint while maintaining rigidity and stability, making it ideal for medium to large size components requiring precise and repetitive operations. Your choice of a cantilever milling machine leverages its efficient space usage and operational versatility, especially in industries demanding intricate milling tasks.

Overview of Portal Milling Machines

Portal milling machines feature a rigid frame with a fixed gantry that supports the milling head, allowing for high precision and stability during heavy-duty machining. This design enables large workpieces to be machined efficiently with consistent accuracy, making it ideal for industrial applications such as aerospace and automotive manufacturing. The fixed gantry and substantial structural support minimize vibrations and deflections, resulting in superior surface finish and extended tool life.

Structural Differences: Cantilever vs Portal Design

Cantilever milling machines feature a single column supporting the spindle arm, allowing increased accessibility and flexibility for machining large or irregularly shaped workpieces. Portal milling machines possess a rigid, overhead gantry structure spanning the worktable, providing exceptional stability and precision for heavy-duty and large-scale machining tasks. The cantilever design offers easier loading and unloading, while the portal's dual supports enhance rigidity and vibration damping during high-precision milling operations.

Precision and Rigidity Comparison

Cantilever milling machines typically offer less rigidity due to their overhanging design, which can lead to slight deflections under heavy cutting loads, affecting precision. Portal milling machines feature a fixed gantry structure that enhances rigidity and minimizes vibrations, resulting in higher precision and consistent machining accuracy. The superior structural stability of portal mills makes them ideal for heavy-duty operations requiring tight tolerances.

Applications and Suitable Workpieces

Cantilever milling machines are ideal for medium to large workpieces requiring high stability, such as aerospace components and mold parts, due to their overhanging structure that allows easy access from multiple sides. Portal milling machines suit heavy-duty applications like machining large gears, engine beds, and shipbuilding parts, offering superior rigidity and precision with their bridge-like frame. Your choice depends on the size and weight of the workpiece, with cantilever machines favoring moderate loads and portal machines excelling at handling massive, complex components.

Space Requirements and Floor Layout

Cantilever milling machines require less floor space due to their single-column design, allowing flexible placement in workshops with limited room. Portal milling machines demand a larger footprint, as their rigid gantry structure spans the entire worktable, necessitating open floor layouts for installation and maintenance. Choosing between the two depends on your space availability and the need for large workpiece handling or compact workshop organization.

Operational Efficiency and Productivity

Cantilever milling machines offer enhanced operational efficiency through their accessible workspace, allowing for easier setup and faster workpiece loading, which reduces downtime. Portal milling machines excel in productivity by supporting larger, heavier workpieces and providing superior rigidity, enabling high-precision machining for complex components. Your choice depends on balancing the need for quick setup with the capacity to handle demanding milling tasks efficiently.

Cost Considerations and Investment

Cantilever milling machines generally offer lower initial costs due to simpler construction and smaller size, making them suitable for budget-conscious workshops. Portal milling machines, with their rigid gantry design, require higher upfront investment but provide superior stability and precision, justifying the expense for complex or high-volume production. Your choice should balance cost considerations with the expected return on investment based on machining accuracy and workload demands.

Choosing the Right Milling Machine for Your Needs

Cantilever milling machines offer versatility and ease of access to the workpiece by supporting the spindle only on one side, making them ideal for smaller, precision tasks and lighter loads. Portal milling machines deliver stability and high rigidity with a fixed bridge design, suitable for heavy-duty machining and large-scale industrial applications requiring excellent vibration resistance. Selecting the right milling machine depends on factors such as the size of the workpiece, machining precision, load capacity, and production volume to optimize efficiency and product quality.

Cantilever vs portal milling machine Infographic

libmatt.com

libmatt.com