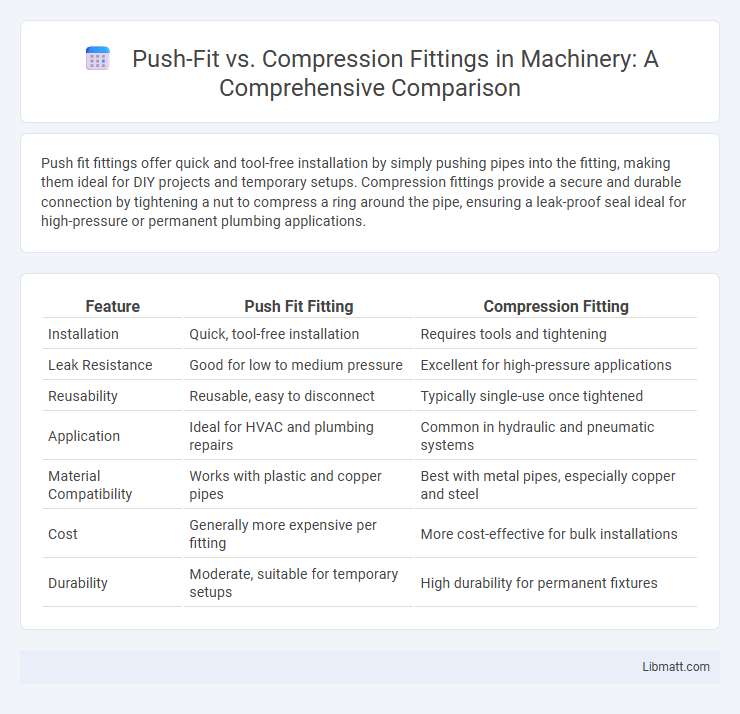

Push fit fittings offer quick and tool-free installation by simply pushing pipes into the fitting, making them ideal for DIY projects and temporary setups. Compression fittings provide a secure and durable connection by tightening a nut to compress a ring around the pipe, ensuring a leak-proof seal ideal for high-pressure or permanent plumbing applications.

Table of Comparison

| Feature | Push Fit Fitting | Compression Fitting |

|---|---|---|

| Installation | Quick, tool-free installation | Requires tools and tightening |

| Leak Resistance | Good for low to medium pressure | Excellent for high-pressure applications |

| Reusability | Reusable, easy to disconnect | Typically single-use once tightened |

| Application | Ideal for HVAC and plumbing repairs | Common in hydraulic and pneumatic systems |

| Material Compatibility | Works with plastic and copper pipes | Best with metal pipes, especially copper and steel |

| Cost | Generally more expensive per fitting | More cost-effective for bulk installations |

| Durability | Moderate, suitable for temporary setups | High durability for permanent fixtures |

Introduction to Plumbing Fittings

Push fit and compression fittings are essential plumbing components used to join pipes securely without soldering or welding. Push fit fittings offer quick, tool-free installation with an internal mechanism that seals and holds pipes in place, making them ideal for repairs and DIY projects. Compression fittings rely on a compression nut and ring to create a watertight seal, providing a robust and reliable connection commonly used in water supply lines and outdoor plumbing.

What is a Push Fit Fitting?

Push fit fittings are plumbing connectors designed for quick and tool-free installation by simply pushing pipes into the fitting until they securely lock in place. These fittings create a watertight seal through an internal O-ring and gripping teeth, making them ideal for DIY projects and repairs where speed and convenience are essential. Your choice of a push fit fitting ensures a reliable connection without soldering or adhesives, reducing installation time and the risk of leaks.

What is a Compression Fitting?

A compression fitting is a type of plumbing connector used to join two pipes or a pipe to a fixture through a tight seal created by compressing a ring or ferrule onto the pipe. It provides a reliable, leak-proof connection without soldering or welding, making installation easier and faster in both residential and commercial plumbing systems. Understanding the function of a compression fitting helps you choose the right method for secure and durable pipe connections.

Key Differences Between Push Fit and Compression Fittings

Push fit fittings allow quick, tool-free installation by simply pushing pipes into the fitting, making them ideal for DIY projects and time-sensitive repairs. Compression fittings require tightening a nut onto a ring (olive) to create a watertight seal, providing a more secure and durable connection suitable for high-pressure systems. Material compatibility and ease of maintenance distinguish push fit fittings, which often cater to plastic pipes, from compression fittings commonly used with copper and metal piping.

Installation Process: Push Fit vs Compression

The installation process of push fit fittings involves simply pushing the pipe into the fitting, creating an instant, secure seal without the need for tools or additional components. Compression fittings require tightening a nut onto a compression ring to create a seal, demanding precise alignment and hand or wrench tightening to avoid leaks. You benefit from faster, tool-free installation with push fit compared to the more involved, though reliable, compression fitting method.

Durability and Longevity Comparison

Push fit fittings offer excellent durability with a corrosion-resistant design, but compression fittings generally provide superior longevity due to their metal-to-metal sealing mechanism that withstands high pressure and temperature variations better. Compression fittings are often preferred in applications requiring long-term reliability and minimal maintenance, as their robust construction resists wear and tear over time. Your choice between push fit and compression fittings should consider the specific demands of your plumbing system to ensure optimal durability and lifespan.

Leakage Risks and Reliability

Push fit fittings offer quick installation with moderate leakage risks, primarily due to improper seating or debris between the pipe and fitting. Compression fittings provide higher reliability under pressure by tightening a metal ring around the pipe, reducing leakage chances when correctly installed. Both require proper technique, but compression fittings generally ensure a more secure, long-lasting seal in high-stress plumbing applications.

Cost Analysis: Push Fit vs Compression

Push fit fittings generally offer a lower upfront cost compared to compression fittings due to their simpler design and quicker installation process. Compression fittings require more precise assembly and often need additional tools, which can increase labor costs and installation time. Over the long term, push fit fittings may reduce overall expenses by minimizing maintenance and replacement frequency, making them a cost-effective choice for many plumbing applications.

Best Applications for Each Fitting Type

Push fit fittings excel in applications requiring quick, tool-free installation and reliable connections in plumbing systems with limited access or frequent maintenance needs. Compression fittings are best suited for high-pressure environments and metal or rigid plastic pipes, offering robust, leak-resistant seals ideal for permanent or semi-permanent installations. Choosing the right fitting depends on your project's demands for ease of installation versus long-term durability and pressure tolerance.

Which Fitting Should You Choose?

Push fit fittings offer quick, tool-free installation ideal for DIY projects and temporary connections, while compression fittings provide a more secure, leak-resistant seal suitable for high-pressure plumbing systems. For applications requiring frequent disassembly or repairs, push fit fittings save time and effort, but compression fittings excel in durability and long-term reliability. Choose push fit for convenience and ease, and compression fitting for robust, permanent pipe connections.

Push fit vs compression fitting Infographic

libmatt.com

libmatt.com