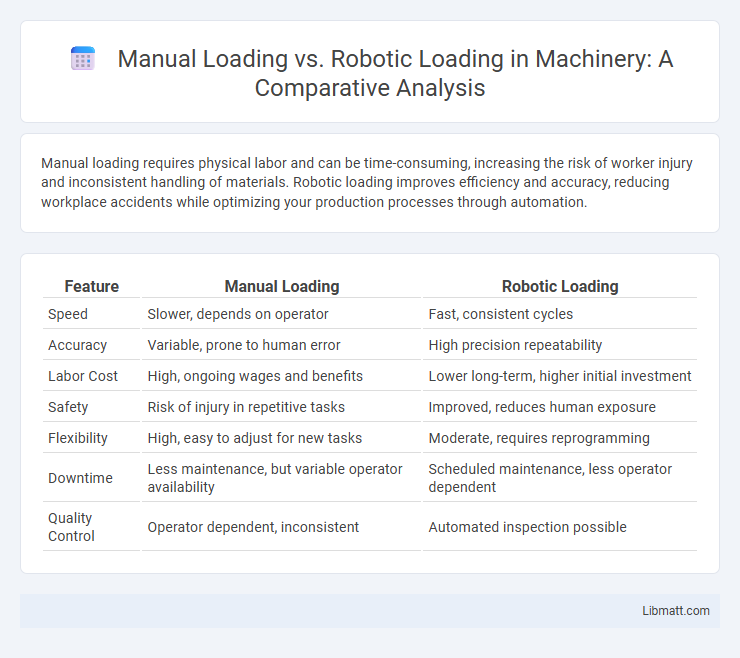

Manual loading requires physical labor and can be time-consuming, increasing the risk of worker injury and inconsistent handling of materials. Robotic loading improves efficiency and accuracy, reducing workplace accidents while optimizing your production processes through automation.

Table of Comparison

| Feature | Manual Loading | Robotic Loading |

|---|---|---|

| Speed | Slower, depends on operator | Fast, consistent cycles |

| Accuracy | Variable, prone to human error | High precision repeatability |

| Labor Cost | High, ongoing wages and benefits | Lower long-term, higher initial investment |

| Safety | Risk of injury in repetitive tasks | Improved, reduces human exposure |

| Flexibility | High, easy to adjust for new tasks | Moderate, requires reprogramming |

| Downtime | Less maintenance, but variable operator availability | Scheduled maintenance, less operator dependent |

| Quality Control | Operator dependent, inconsistent | Automated inspection possible |

Introduction to Loading Methods

Manual loading involves human workers physically handling and placing items onto vehicles or storage areas, which can be labor-intensive and time-consuming. Robotic loading uses automated machinery and robots to move and position goods, increasing efficiency, consistency, and safety in warehouses or production lines. Your choice between these methods affects productivity, operational costs, and workplace ergonomics significantly.

Overview of Manual Loading

Manual loading involves human workers physically handling, lifting, and placing goods onto pallets, conveyors, or transport vehicles, offering flexibility for irregular or delicate items. It requires significant labor, increasing the risk of workplace injuries and reducing efficiency compared to automation. Despite these challenges, manual loading remains essential in industries with low-volume or customized orders where robotic systems may lack adaptability.

Overview of Robotic Loading

Robotic loading automates material handling processes using advanced robotic arms and AI-driven systems to enhance precision and efficiency in industrial operations. This technology reduces human labor costs, minimizes workplace injuries, and increases throughput by consistently performing repetitive loading tasks with high accuracy. Integration with smart factory systems allows real-time monitoring and optimization, making robotic loading a critical component in modern manufacturing and logistics.

Efficiency Comparison: Manual vs Robotic

Robotic loading systems consistently outperform manual loading in efficiency by handling repetitive tasks faster and with greater precision, reducing cycle times and minimizing errors. Manual loading depends heavily on human labor, leading to variability in speed and increased fatigue, which can decrease overall productivity. Implementing robotic loading can optimize your workflow by ensuring continuous operation and improved throughput in material handling processes.

Safety Considerations in Loading Operations

Manual loading poses higher safety risks due to physical strain and potential for human error, often leading to injuries such as cuts, bruises, or musculoskeletal disorders. Robotic loading enhances safety by minimizing human involvement in hazardous tasks, reducing accidents and exposure to dangerous environments. Your operation benefits from improved worker safety protocols and compliance with occupational health standards through robotic automation.

Cost Analysis: Initial and Ongoing Expenses

Manual loading involves lower initial investment costs due to minimal equipment requirements but incurs higher ongoing labor expenses and potential inefficiencies. Robotic loading demands significant upfront capital for advanced machinery and integration but reduces long-term operational costs through consistent productivity and lower labor dependency. Evaluating your workflow volume and budget constraints helps determine the most cost-effective approach between manual and robotic loading solutions.

Flexibility and Adaptability in Loading Processes

Manual loading offers superior flexibility and adaptability, allowing workers to adjust to varying product types, sizes, and packaging without significant interruption. Robotic loading excels in consistency and speed but often requires pre-programmed settings and may struggle with unexpected changes or irregular items. Industries prioritizing dynamic workflows benefit from manual loading, whereas high-volume, repetitive tasks favor robotic solutions for streamlined efficiency.

Impact on Workforce and Labor Dynamics

Manual loading relies heavily on human labor, resulting in higher physical strain and injury risks for workers while offering greater flexibility in handling diverse products. Robotic loading automates repetitive tasks, reducing labor costs and minimizing workplace injuries but may lead to workforce displacement and necessitate reskilling efforts. Your business must balance efficiency gains from robotics with the social and economic impacts on the existing workforce to ensure sustainable labor dynamics.

Maintenance and Downtime Challenges

Manual loading processes often experience increased downtime due to human error and inconsistent maintenance schedules, leading to frequent equipment adjustments and repairs. Robotic loading systems require specialized maintenance, including software updates and sensor calibrations, which can reduce unplanned downtime but may demand higher technical expertise. Predictive maintenance technology integrated with robotics enables early detection of potential failures, minimizing downtime and optimizing operational efficiency.

Choosing the Right Loading Solution for Your Business

Selecting the right loading solution depends on factors such as production volume, budget, and workforce availability. Manual loading offers flexibility and lower upfront costs but may lead to slower throughput and higher labor expenses. Robotic loading enhances efficiency, accuracy, and safety, making it ideal for high-volume operations despite higher initial investment.

Manual loading vs robotic loading Infographic

libmatt.com

libmatt.com