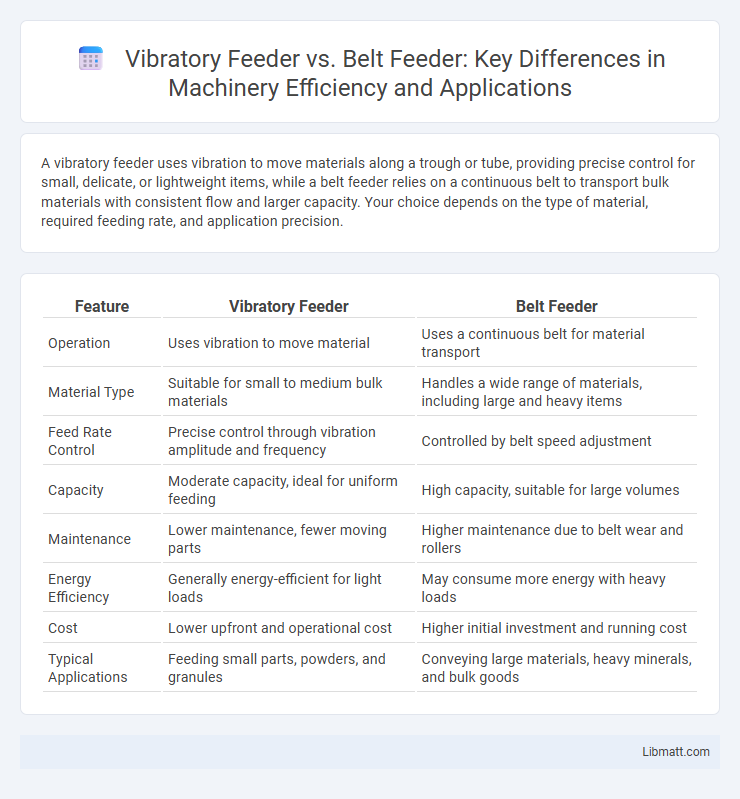

A vibratory feeder uses vibration to move materials along a trough or tube, providing precise control for small, delicate, or lightweight items, while a belt feeder relies on a continuous belt to transport bulk materials with consistent flow and larger capacity. Your choice depends on the type of material, required feeding rate, and application precision.

Table of Comparison

| Feature | Vibratory Feeder | Belt Feeder |

|---|---|---|

| Operation | Uses vibration to move material | Uses a continuous belt for material transport |

| Material Type | Suitable for small to medium bulk materials | Handles a wide range of materials, including large and heavy items |

| Feed Rate Control | Precise control through vibration amplitude and frequency | Controlled by belt speed adjustment |

| Capacity | Moderate capacity, ideal for uniform feeding | High capacity, suitable for large volumes |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance due to belt wear and rollers |

| Energy Efficiency | Generally energy-efficient for light loads | May consume more energy with heavy loads |

| Cost | Lower upfront and operational cost | Higher initial investment and running cost |

| Typical Applications | Feeding small parts, powders, and granules | Conveying large materials, heavy minerals, and bulk goods |

Introduction to Vibratory Feeders and Belt Feeders

Vibratory feeders use vibrations to move materials precisely along a feeder tray, ideal for controlled feeding and sorting of small components in manufacturing lines. Belt feeders rely on a continuous conveyor belt to transport bulk materials efficiently, offering smooth and steady feeding suitable for heavier loads and larger volumes. Your choice between vibratory and belt feeders depends on the material type, feed rate requirements, and application-specific precision needs.

Core Principles of Vibratory Feeder Operation

Vibratory feeders operate based on the principle of controlled vibration to move materials along a trough or tube, using electromagnetic or mechanical drives to generate consistent oscillations. The frequency and amplitude of these vibrations can be precisely adjusted to regulate the flow rate of bulk materials, ensuring efficient feeding and positioning. Your choice between a vibratory feeder and a belt feeder depends on the need for gentle handling, accurate dosing, and the specific bulk material characteristics.

How Belt Feeders Work: An Overview

Belt feeders operate by using a continuous belt to transport bulk materials at a controlled rate, driven by an electric motor connected to pulleys. The system maintains precise flow regulation suitable for heavy or abrasive materials, ensuring consistent discharge rates in processing operations. Compared to vibratory feeders, belt feeders excel in handling larger capacities and providing gentle material handling with minimal degradation.

Key Differences Between Vibratory and Belt Feeders

Vibratory feeders use vibration to move materials along a tray, offering precise control for small to medium-sized loads and fine materials, while belt feeders employ a continuous belt for steady, heavy-duty material handling and bulkier items. The key differences include the motion mechanism, with vibratory feeders relying on oscillations and belt feeders using friction-based belt movement, affecting speed consistency and material suitability. Your choice depends on factors such as material type, required feed accuracy, and operational environment, making vibratory feeders ideal for delicate or abrasive materials and belt feeders better for high-capacity, uniform flow applications.

Material Handling Efficiency Comparison

Vibratory feeders excel in handling small to medium-sized granular or powder materials with precision and high-speed feeding rates, enhancing your processing line's efficiency. Belt feeders are preferred for moving larger, heavier, or bulkier materials consistently over longer distances, providing smooth and reliable transport with minimal material degradation. Comparing material handling efficiency, vibratory feeders offer superior control and accuracy, whereas belt feeders deliver better capacity and gentle material handling for diverse industrial applications.

Applications Best Suited for Vibratory Feeders

Vibratory feeders excel in precise material handling tasks, commonly used for feeding small parts in assembly lines, packaging, and pharmaceutical industries. These feeders are ideal for applications requiring gentle, controlled feeding of fine, fragile, or abrasive materials. Your choice of a vibratory feeder ensures efficient sorting and orientation, especially in high-speed automated processes.

Ideal Use Cases for Belt Feeders

Belt feeders are ideal for handling large, heavy, or abrasive materials in industries such as mining, cement production, and bulk material handling, where consistent and controlled material flow is crucial. Their design allows for smooth and continuous feeding of materials like coal, ore, and aggregates over long distances or steep inclines. Belt feeders excel in applications requiring precise feed rate control and minimal material degradation.

Maintenance and Durability Considerations

Vibratory feeders require regular inspection of springs and motor parts to prevent wear and ensure consistent operation, while belt feeders demand frequent belt tension checks and roller alignments to avoid slippage and premature belt degradation. Durability of vibratory feeders is enhanced by their robust construction, making them ideal for handling abrasive materials, whereas belt feeders, with their flexible belt surfaces, are better suited for delicate or sticky substances but may experience faster wear in harsh conditions. Maintenance costs for vibratory feeders are generally lower due to fewer moving parts, but belt feeders offer easier replacement of components, facilitating quicker turnaround during repairs.

Cost Comparison: Vibratory vs Belt Feeders

Vibratory feeders generally have lower initial costs and require less maintenance compared to belt feeders, making them cost-effective for precise dosing and small to medium-sized material handling tasks. Belt feeders often involve higher upfront investment due to complex components and motor requirements but provide better performance for handling heavier, bulk materials over longer distances. Your choice depends on balancing budget constraints with operational needs, considering both upfront costs and long-term maintenance expenses.

Choosing the Right Feeder for Your Application

Selecting the ideal feeder for your application hinges on factors such as material type, flow rate, and precision requirements. Vibratory feeders excel in handling fragile, fine, or small parts with precise control and uniform distribution, making them suitable for packaging and assembly lines. Belt feeders provide robust, continuous feeding for heavy or abrasive materials, ideal for bulk handling in industries like mining and construction.

Vibratory feeder vs belt feeder Infographic

libmatt.com

libmatt.com