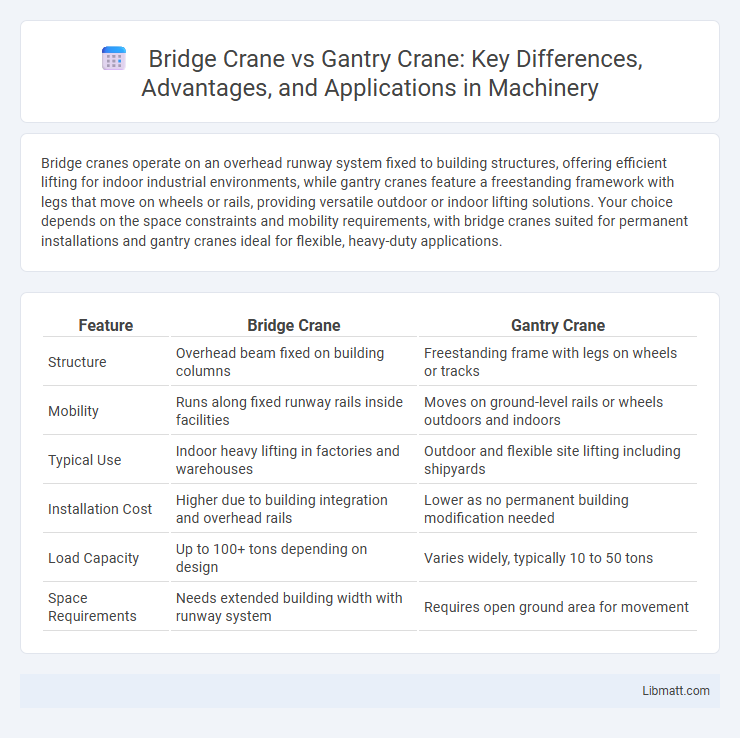

Bridge cranes operate on an overhead runway system fixed to building structures, offering efficient lifting for indoor industrial environments, while gantry cranes feature a freestanding framework with legs that move on wheels or rails, providing versatile outdoor or indoor lifting solutions. Your choice depends on the space constraints and mobility requirements, with bridge cranes suited for permanent installations and gantry cranes ideal for flexible, heavy-duty applications.

Table of Comparison

| Feature | Bridge Crane | Gantry Crane |

|---|---|---|

| Structure | Overhead beam fixed on building columns | Freestanding frame with legs on wheels or tracks |

| Mobility | Runs along fixed runway rails inside facilities | Moves on ground-level rails or wheels outdoors and indoors |

| Typical Use | Indoor heavy lifting in factories and warehouses | Outdoor and flexible site lifting including shipyards |

| Installation Cost | Higher due to building integration and overhead rails | Lower as no permanent building modification needed |

| Load Capacity | Up to 100+ tons depending on design | Varies widely, typically 10 to 50 tons |

| Space Requirements | Needs extended building width with runway system | Requires open ground area for movement |

Overview of Bridge Cranes and Gantry Cranes

Bridge cranes consist of a hoist system mounted on a horizontal beam that runs along elevated runways, primarily used for indoor material handling in warehouses and manufacturing plants. Gantry cranes feature a similar hoist mounted on a bridge supported by freestanding legs that move on ground-level rails, offering mobility and versatility for outdoor or heavy-lifting applications. Understanding the differences helps you select the ideal crane system tailored to your facility's spatial constraints and operational needs.

Key Structural Differences

Bridge cranes feature a horizontal beam called a bridge that spans the width of a workspace and moves along parallel runways, supported by an overhead structure. Gantry cranes have a similar horizontal beam but are supported by legs that move on ground-level tracks, allowing them to operate without the need for an overhead building structure. The primary structural difference lies in bridge cranes being suspended from above, while gantry cranes are self-supporting with mobile legs on the floor.

Typical Applications and Industries

Bridge cranes, commonly found in manufacturing plants and warehouses, excel at lifting heavy loads across fixed pathways, making them ideal for automotive assembly, steel production, and shipbuilding industries. Gantry cranes, with their versatility and mobility, are widely used in outdoor construction sites, container yards, and freight handling, accommodating industries like shipping, logistics, and large-scale infrastructure projects. Your choice depends on whether your operation requires fixed overhead lifting or flexible, ground-level movement for heavy materials.

Load Capacity Comparison

Bridge cranes typically offer higher load capacities ranging from 1 to over 100 tons, making them ideal for heavy industrial applications. Gantry cranes generally support lighter loads, often between 0.5 to 50 tons, suited for outdoor or mobile lifting tasks. The structural design of bridge cranes allows for greater stability under heavy loads compared to gantry cranes.

Installation Requirements

Bridge cranes require a robust overhead runway system with structural support integrated into the building, demanding precise engineering and higher upfront installation costs. Gantry cranes feature a self-supporting framework that typically eliminates the need for permanent building modifications, making them easier to install outdoors or in areas with limited overhead structures. Your choice depends on available building infrastructure and the flexibility needed for installation location.

Mobility and Flexibility

Bridge cranes offer limited mobility as they are fixed to a runway system within a building, providing excellent flexibility in horizontal movement but confined to a defined area. Gantry cranes feature greater overall mobility, as they can move independently on ground-level rails or tires, enabling them to operate across different work sites or open spaces without the need for permanent infrastructure. The flexibility of gantry cranes makes them ideal for outdoor or heavy-duty lifting tasks where versatility in positioning is crucial.

Cost Considerations

Bridge cranes generally have higher initial costs due to their permanent installation and integration within existing building structures, while gantry cranes tend to be more cost-effective with lower setup expenses because of their freestanding design. Maintenance costs for bridge cranes can be lower over time since they operate within a controlled environment, whereas gantry cranes may incur higher maintenance expenses due to exposure to outdoor elements. Choosing between the two depends on the specific application requirements, operational environment, and budget constraints.

Safety Features and Protocols

Bridge cranes feature enclosed runways and overhead structures that reduce the risk of collision and falling objects, enhancing workplace safety. Gantry cranes often include safety interlocks and emergency stop systems to prevent accidents during operation in open or outdoor environments. Your choice should consider which safety protocols best align with your worksite conditions and compliance requirements.

Maintenance and Longevity

Bridge cranes typically require regular lubrication of runway rails and trolley wheels, along with routine inspection of wire ropes and electrical systems to ensure longevity. Gantry cranes demand frequent examination of support legs and wheels, as well as rust prevention measures due to their exposure in outdoor environments, which can affect maintenance frequency. Proper maintenance schedules and high-quality components directly extend the service life of both bridge and gantry cranes, reducing downtime and operational costs.

Choosing the Right Crane for Your Needs

When choosing the right crane for your needs, consider that bridge cranes, also known as overhead cranes, are ideal for indoor applications with fixed runways, offering precise movement across a facility. Gantry cranes provide greater flexibility, as their supporting structure is portable and can be used both indoors and outdoors for heavy lifting tasks in shipyards or construction sites. Evaluating your workspace layout, load capacity, and mobility requirements ensures you select the crane best suited to optimize your operational efficiency.

Bridge crane vs gantry crane Infographic

libmatt.com

libmatt.com