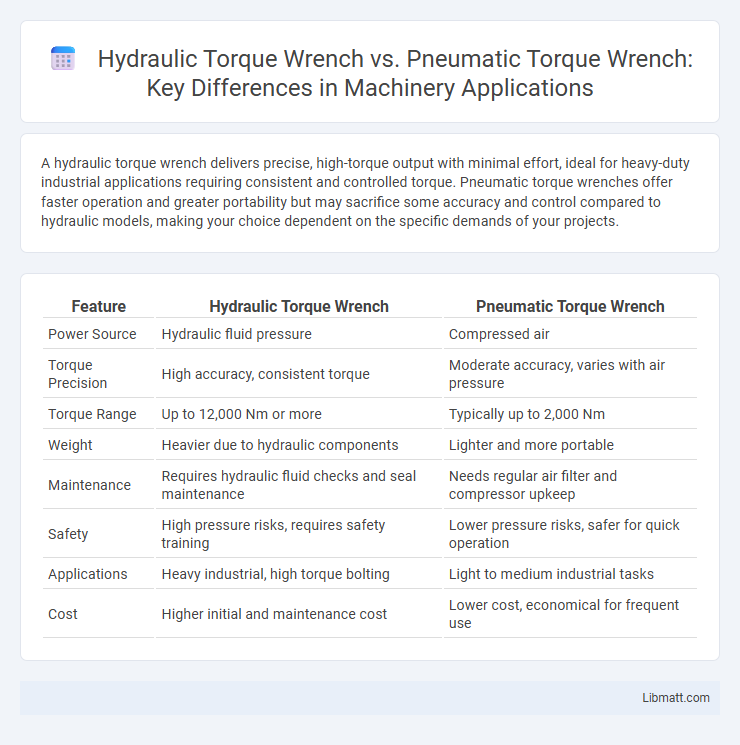

A hydraulic torque wrench delivers precise, high-torque output with minimal effort, ideal for heavy-duty industrial applications requiring consistent and controlled torque. Pneumatic torque wrenches offer faster operation and greater portability but may sacrifice some accuracy and control compared to hydraulic models, making your choice dependent on the specific demands of your projects.

Table of Comparison

| Feature | Hydraulic Torque Wrench | Pneumatic Torque Wrench |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Compressed air |

| Torque Precision | High accuracy, consistent torque | Moderate accuracy, varies with air pressure |

| Torque Range | Up to 12,000 Nm or more | Typically up to 2,000 Nm |

| Weight | Heavier due to hydraulic components | Lighter and more portable |

| Maintenance | Requires hydraulic fluid checks and seal maintenance | Needs regular air filter and compressor upkeep |

| Safety | High pressure risks, requires safety training | Lower pressure risks, safer for quick operation |

| Applications | Heavy industrial, high torque bolting | Light to medium industrial tasks |

| Cost | Higher initial and maintenance cost | Lower cost, economical for frequent use |

Introduction to Hydraulic and Pneumatic Torque Wrenches

Hydraulic torque wrenches use fluid pressure to generate precise, high-torque output ideal for heavy-duty bolting in industries like construction and oil and gas. Pneumatic torque wrenches rely on compressed air to deliver rapid torque application, making them suitable for lighter to medium-duty tasks with faster operation speeds. Understanding your specific torque requirements and work environment helps determine whether a hydraulic or pneumatic torque wrench best suits your needs.

How Hydraulic Torque Wrenches Work

Hydraulic torque wrenches operate by converting hydraulic pressure into torque through a piston-cylinder mechanism that drives a reaction arm and output shaft, delivering precise and consistent tightening force. The hydraulic fluid under pressure moves the piston, which rotates the wrench's reaction arm, allowing controlled application of torque ideal for high-torque bolting tasks. This system provides superior accuracy and repeatability compared to pneumatic torque wrenches, making hydraulic models essential for heavy-duty industrial applications.

How Pneumatic Torque Wrenches Operate

Pneumatic torque wrenches operate using compressed air to generate rotational force, enabling precise tightening or loosening of bolts with consistent torque output. These tools convert air pressure into mechanical power through pistons and gears, allowing for rapid and efficient operation in industrial settings. Pneumatic torque wrenches are favored for applications requiring high torque and continuous use without overheating.

Power and Torque Output Comparison

Hydraulic torque wrenches deliver significantly higher torque output, ranging from 300 to over 100,000 Nm, making them ideal for heavy-duty industrial applications requiring precise and powerful fastening. Pneumatic torque wrenches typically offer lower torque levels, usually between 50 and 1,000 Nm, best suited for medium-duty tasks with faster cycle times. Understanding the power and torque output differences helps you select the optimal tool for your specific torque requirements and operational efficiency.

Accuracy and Precision: Which Wins?

Hydraulic torque wrenches offer superior accuracy and precision due to their controlled hydraulic pressure, delivering consistent torque output essential for critical applications. Pneumatic torque wrenches, while effective for rapid tasks, tend to have variable torque control influenced by air pressure fluctuations, making them less precise. Your choice should prioritize hydraulic models when consistent torque values and high accuracy are paramount for safety and equipment integrity.

Speed and Efficiency in Industrial Applications

Hydraulic torque wrenches deliver precise, high-torque output with controlled speed, making them ideal for heavy-duty industrial applications requiring consistent accuracy and repeatability. Pneumatic torque wrenches offer faster operation speeds but can sacrifice precision, which may lead to variability in torque application during high-volume tasks. Your choice between these tools depends on balancing the need for rapid assembly with stringent torque accuracy in demanding production environments.

Maintenance and Longevity Considerations

Hydraulic torque wrenches require regular inspection of hoses and seals to prevent fluid leaks, ensuring consistent calibration and extended tool lifespan. Pneumatic torque wrenches demand frequent air filter replacements and lubrication of moving parts to avoid moisture-related corrosion and maintain optimal performance. Proper maintenance practices significantly influence the longevity of both types, with hydraulic tools generally offering greater durability under heavy-duty applications.

Safety Features and Operational Risks

Hydraulic torque wrenches offer superior safety features due to their controlled pressure systems and reduced risk of air leakage, minimizing potential hazards during operation. Pneumatic torque wrenches, while efficient, pose higher operational risks such as sudden air bursts and inconsistent torque application, which can lead to operator injury or equipment damage. Choosing hydraulic models enhances operator protection by providing precise torque control and lower incident rates in industrial environments.

Cost Analysis: Hydraulic vs Pneumatic

Hydraulic torque wrenches typically entail higher upfront costs due to their robust construction and precision components, while pneumatic torque wrenches offer a more budget-friendly purchase price suitable for lighter-duty applications. Operating expenses for hydraulic tools can be greater because of maintenance requirements and the need for hydraulic fluid, whereas pneumatic tools rely on compressed air, which may increase energy costs depending on the compressor efficiency. Your choice should weigh initial investment against long-term operating costs, considering factors such as application frequency, required torque accuracy, and maintenance capabilities.

Choosing the Right Torque Wrench for Your Needs

Selecting the right torque wrench depends on your specific application requirements and operational environment. Hydraulic torque wrenches offer higher torque output and precision, making them ideal for heavy-duty tasks and maintenance in industrial settings. Pneumatic torque wrenches provide faster operation and are suitable for repetitive fastening jobs where moderate torque is sufficient, helping you achieve efficiency without compromising control.

Hydraulic torque wrench vs pneumatic torque wrench Infographic

libmatt.com

libmatt.com