Synchronous belts and timing belts are often used interchangeably to describe toothed belts designed for precise mechanical synchronization between components, ensuring no slippage occurs. Your choice between the two depends on the specific application requirements, as both offer reliable power transmission with accurate timing in engines and machinery.

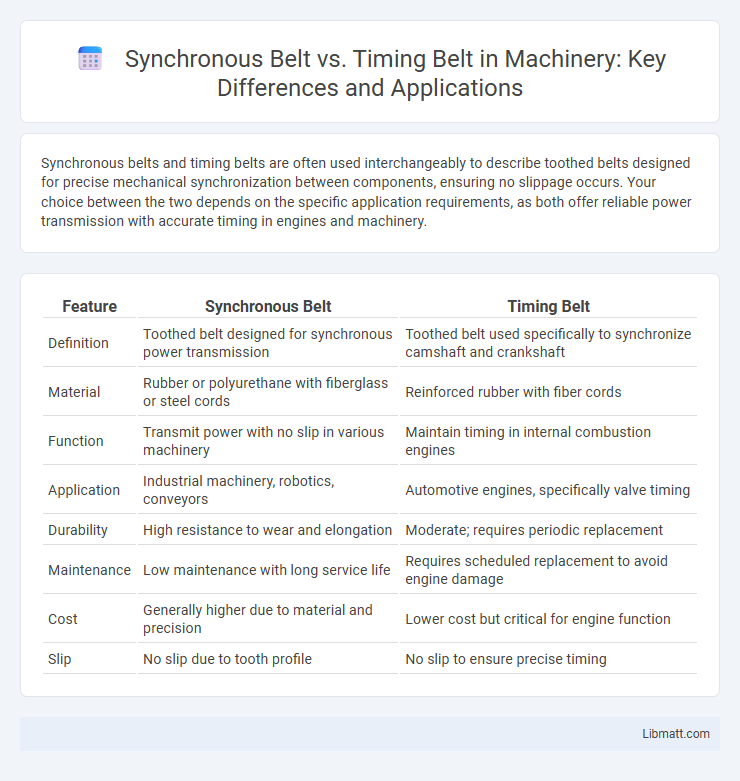

Table of Comparison

| Feature | Synchronous Belt | Timing Belt |

|---|---|---|

| Definition | Toothed belt designed for synchronous power transmission | Toothed belt used specifically to synchronize camshaft and crankshaft |

| Material | Rubber or polyurethane with fiberglass or steel cords | Reinforced rubber with fiber cords |

| Function | Transmit power with no slip in various machinery | Maintain timing in internal combustion engines |

| Application | Industrial machinery, robotics, conveyors | Automotive engines, specifically valve timing |

| Durability | High resistance to wear and elongation | Moderate; requires periodic replacement |

| Maintenance | Low maintenance with long service life | Requires scheduled replacement to avoid engine damage |

| Cost | Generally higher due to material and precision | Lower cost but critical for engine function |

| Slip | No slip due to tooth profile | No slip to ensure precise timing |

Introduction to Synchronous and Timing Belts

Synchronous belts and timing belts both function as precise mechanical components designed to transfer rotational motion with minimal slippage. Synchronous belts typically feature trapezoidal or curvilinear teeth profiles that engage matching pulleys for consistent power transmission, while timing belts are a subtype of synchronous belts specifically engineered to maintain exact timing between engine components. These belts are essential in automotive and industrial applications where accurate synchronization and efficient power transfer are critical.

How Synchronous Belts Work

Synchronous belts operate by engaging with matching toothed pulleys, transferring rotary motion without slippage and maintaining precise timing between engine components. Constructed from rubber or polyurethane with embedded fiberglass or steel cords, these belts ensure high tensile strength and durability under varying loads. Their design enables efficient power transmission in automotive engines and industrial machinery, reducing wear and enhancing synchronization accuracy.

How Timing Belts Function

Timing belts function by synchronizing the rotation of the crankshaft and camshaft in an engine, ensuring precise valve timing for optimal engine performance. Constructed from reinforced rubber with teeth that mesh perfectly with the pulleys, timing belts prevent slippage and maintain accurate engine timing. Your engine relies on this synchronization to avoid valve damage and maintain smooth operation.

Key Differences Between Synchronous and Timing Belts

Synchronous belts and timing belts both provide precise mechanical synchronization but differ in material composition and applications. Synchronous belts typically utilize polyurethane with steel cords, offering higher durability and resistance to chemicals, while timing belts use rubber with fiberglass cords, delivering greater flexibility and quieter operation. Key differences include synchronous belts' superior load capacity and temperature resistance contrasted with timing belts' ease of installation and cost-effectiveness in automotive engines.

Material Composition and Durability

Synchronous belts and timing belts are often terms used interchangeably, as both typically feature a rubber or polyurethane body reinforced with fiberglass, Kevlar, or steel cords for strength. The durability of synchronous belts depends on the specific material composition; polyurethane belts offer higher resistance to chemicals and abrasion compared to rubber-based timing belts, making them better suited for demanding industrial applications. Your choice should consider operating conditions, as polyurethane synchronous belts generally provide superior longevity and wear resistance under high-stress environments.

Performance and Efficiency Comparison

Synchronous belts and timing belts both provide precise power transmission with minimal slip, but synchronous belts typically offer higher efficiency due to their stronger, more durable materials and less frictional loss. Timing belts are designed specifically for engine timing in automotive applications, delivering reliable, consistent synchronization under varying loads, while synchronous belts excel in industrial machinery requiring high torque and longer service life. Your choice depends on the application's demand for durability, load capacity, and operational smoothness to optimize performance and efficiency.

Applications in Industrial Machinery

Synchronous belts and timing belts are essential components in industrial machinery, offering precise power transmission and synchronized motion control. Synchronous belts are commonly used in high-performance applications such as conveyor systems, packaging machines, and CNC equipment due to their ability to maintain exact timing and reduce slippage. Timing belts, a type of synchronous belt with toothed profiles, are preferred in automotive engines, printing presses, and robotics where accurate timing between moving parts is critical for operational efficiency and durability.

Maintenance and Lifespan Considerations

Synchronous belts and timing belts both require regular inspection to maintain optimal performance and prevent unexpected failures, with synchronous belts typically benefiting from less frequent maintenance due to their construction materials. The lifespan of synchronous belts often exceeds that of traditional timing belts, as they are designed to resist wear, heat, and contamination more effectively, extending intervals between replacements. Understanding your equipment's specific operational conditions will help you determine the best maintenance schedule to maximize durability and efficiency.

Cost Analysis: Synchronous vs Timing Belts

Synchronous belts generally offer a cost-effective solution compared to timing belts due to their simpler design and lower material expenses, making them ideal for budget-conscious applications. Timing belts, while more expensive, provide superior precision and durability, justifying the higher cost in high-performance or critical timing scenarios. Businesses must evaluate initial costs against long-term maintenance and replacement expenses to determine the most cost-efficient option for their specific mechanical system needs.

Choosing the Right Belt for Your Needs

Choosing the right belt for your needs involves understanding the differences between synchronous belts and timing belts, both designed to transfer motion with precise timing. Synchronous belts feature toothed designs that engage with matching pulleys, ideal for high-speed applications requiring minimal slippage and accurate synchronization. Timing belts, often used in automotive engines, maintain engine timing by preventing camshaft slippage while offering smooth operation and noise reduction.

Synchronous belt vs timing belt Infographic

libmatt.com

libmatt.com