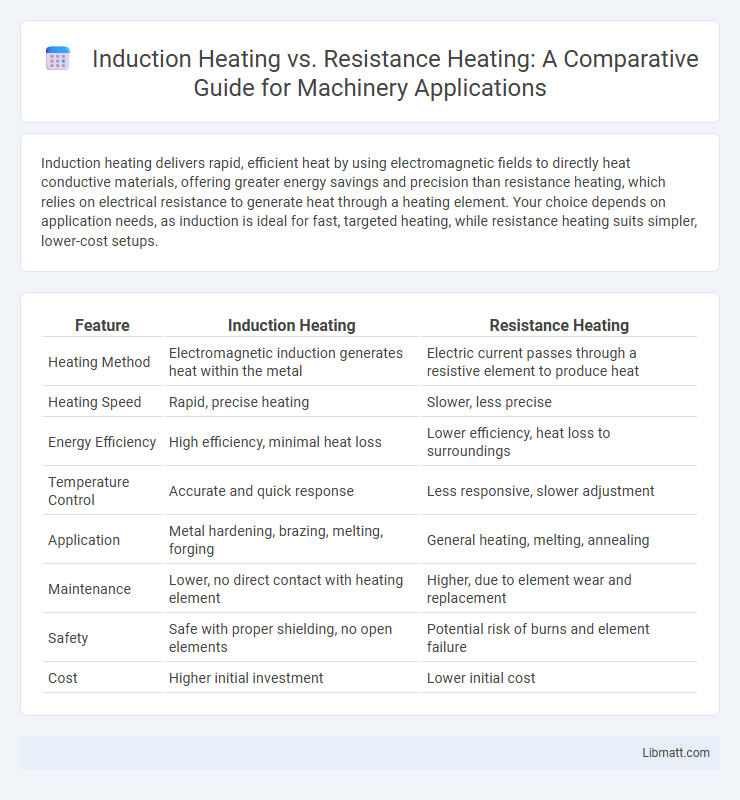

Induction heating delivers rapid, efficient heat by using electromagnetic fields to directly heat conductive materials, offering greater energy savings and precision than resistance heating, which relies on electrical resistance to generate heat through a heating element. Your choice depends on application needs, as induction is ideal for fast, targeted heating, while resistance heating suits simpler, lower-cost setups.

Table of Comparison

| Feature | Induction Heating | Resistance Heating |

|---|---|---|

| Heating Method | Electromagnetic induction generates heat within the metal | Electric current passes through a resistive element to produce heat |

| Heating Speed | Rapid, precise heating | Slower, less precise |

| Energy Efficiency | High efficiency, minimal heat loss | Lower efficiency, heat loss to surroundings |

| Temperature Control | Accurate and quick response | Less responsive, slower adjustment |

| Application | Metal hardening, brazing, melting, forging | General heating, melting, annealing |

| Maintenance | Lower, no direct contact with heating element | Higher, due to element wear and replacement |

| Safety | Safe with proper shielding, no open elements | Potential risk of burns and element failure |

| Cost | Higher initial investment | Lower initial cost |

Introduction to Induction and Resistance Heating

Induction heating uses electromagnetic fields to directly heat conductive materials through eddy currents, offering precise and rapid temperature control ideal for metal processing and manufacturing applications. Resistance heating relies on the flow of electrical current through a resistive element, converting electrical energy into heat, commonly used in appliances and industrial heating systems due to its simplicity and cost-effectiveness. Understanding these fundamental differences in heating mechanisms can help you select the most efficient and suitable method for your specific thermal processing needs.

Principles of Induction Heating

Induction heating operates on the principle of electromagnetic induction, where alternating current passes through a coil, generating a varying magnetic field that induces eddy currents within the conductive material. These eddy currents produce localized heat due to the material's electrical resistance, enabling rapid and precise heating without direct contact. This method contrasts with resistance heating, which relies on direct electrical current flowing through the resistive element to generate heat.

Fundamentals of Resistance Heating

Resistance heating relies on the principle that an electric current passing through a conductor generates heat due to the material's electrical resistance, converting electrical energy into thermal energy efficiently. Common in applications like toasters and electric heaters, this method uses resistive elements such as nichrome wires to produce consistent and controllable heat. Your choice between resistance and induction heating depends on factors like speed, energy efficiency, and the specific heating requirements of your application.

Key Differences Between Induction and Resistance Heating

Induction heating uses electromagnetic fields to directly heat conductive materials, resulting in rapid and precise temperature control, while resistance heating relies on electric current passing through a resistive element to generate heat. Induction heating offers higher energy efficiency and faster response times compared to resistance heating, which typically has slower heating rates and less precise control. Maintenance costs are lower for induction systems since they experience less wear and have no physical heating elements exposed to high temperatures, unlike resistance heating systems.

Efficiency Comparison: Induction vs Resistance Heating

Induction heating achieves higher energy efficiency by directly generating heat within the metal workpiece through electromagnetic fields, reducing heat loss compared to resistance heating, which relies on electrical current passing through a resistive element. Induction systems typically reach efficiency rates of 85-90%, whereas resistance heating often operates around 70-80% due to heat dissipation from elements and surrounding materials. The rapid heating capability and precise control of induction heating contribute to reduced energy consumption and operational costs in industrial applications.

Typical Applications of Induction Heating

Induction heating is widely used in metal hardening, brazing, and annealing processes due to its precise control and rapid heating capabilities. It is commonly employed in automotive, aerospace, and electronics industries for tasks like gear heating, wire bonding, and surface treatment. This method is preferred for applications requiring focused, clean, and energy-efficient heating without direct contact.

Typical Applications of Resistance Heating

Resistance heating is commonly applied in household appliances like toasters, ovens, and electric heaters due to its efficiency in converting electrical energy directly into heat. Industrial processes such as metal forging, plastic molding, and annealing rely on resistance heating for precise temperature control and uniform heat distribution. Your choice between induction heating and resistance heating depends on application-specific requirements like heating speed, energy efficiency, and material compatibility.

Advantages and Disadvantages of Induction Heating

Induction heating offers rapid, precise, and energy-efficient heating by directly inducing electric currents within the material, reducing heat loss and processing time compared to resistance heating. It provides superior control over temperature and localized heating, minimizing distortion and extending tool life, but incurs higher initial equipment costs and requires conductive materials for effective heating. Resistance heating is simpler and cheaper but suffers from slower response times, uneven heating, and higher energy consumption due to indirect heat transfer through resistive elements.

Pros and Cons of Resistance Heating

Resistance heating offers precise temperature control and uniform heating suitable for a wide range of materials and applications. It is generally cost-effective with simple equipment requirements, but it tends to have slower heating times and lower energy efficiency compared to induction heating. Resistance heating elements are prone to wear and require periodic replacement, which can increase maintenance costs over time.

Choosing the Right Heating Method for Your Application

Induction heating offers rapid, precise temperature control ideal for applications requiring localized heat and energy efficiency, such as metal hardening or brazing. Resistance heating provides uniform heat distribution over larger surfaces, making it suitable for processes like plastic forming or batch ovens. Selecting the appropriate method depends on material properties, desired heating speed, energy consumption, and specific application requirements.

Induction heating vs resistance heating Infographic

libmatt.com

libmatt.com