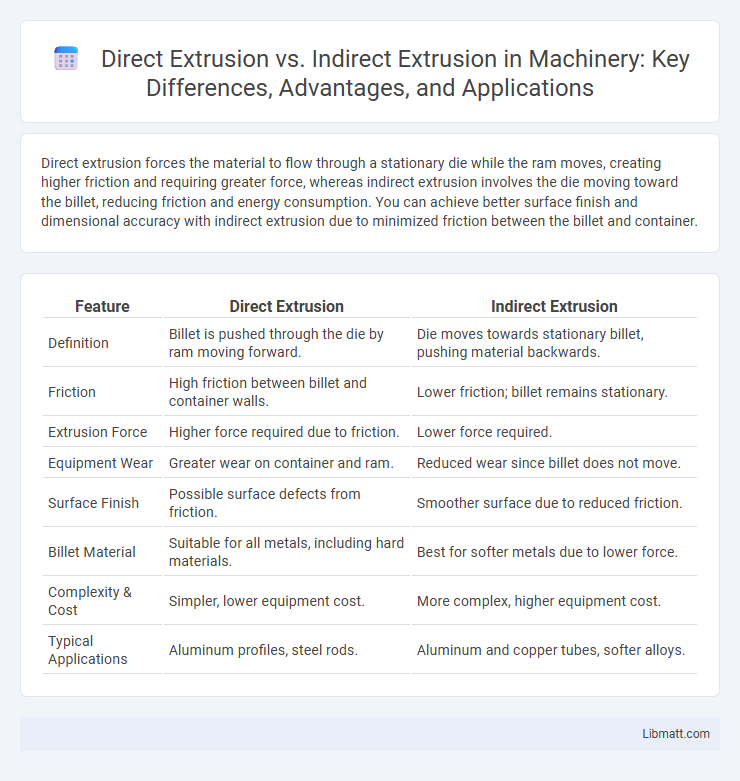

Direct extrusion forces the material to flow through a stationary die while the ram moves, creating higher friction and requiring greater force, whereas indirect extrusion involves the die moving toward the billet, reducing friction and energy consumption. You can achieve better surface finish and dimensional accuracy with indirect extrusion due to minimized friction between the billet and container.

Table of Comparison

| Feature | Direct Extrusion | Indirect Extrusion |

|---|---|---|

| Definition | Billet is pushed through the die by ram moving forward. | Die moves towards stationary billet, pushing material backwards. |

| Friction | High friction between billet and container walls. | Lower friction; billet remains stationary. |

| Extrusion Force | Higher force required due to friction. | Lower force required. |

| Equipment Wear | Greater wear on container and ram. | Reduced wear since billet does not move. |

| Surface Finish | Possible surface defects from friction. | Smoother surface due to reduced friction. |

| Billet Material | Suitable for all metals, including hard materials. | Best for softer metals due to lower force. |

| Complexity & Cost | Simpler, lower equipment cost. | More complex, higher equipment cost. |

| Typical Applications | Aluminum profiles, steel rods. | Aluminum and copper tubes, softer alloys. |

Introduction to Extrusion Processes

Extrusion processes involve shaping material by forcing it through a die to create continuous profiles with specific cross-sections. Direct extrusion pushes the billet through the die using a ram, causing friction between the billet and container, while indirect extrusion moves the die towards the billet, significantly reducing friction. Understanding the differences in force requirements and material flow patterns is essential for optimizing extrusion efficiency and product quality.

What is Direct Extrusion?

Direct extrusion, also known as forward extrusion, involves pushing the billet through a stationary die by a ram, resulting in the material flowing in the same direction as the ram movement. This process is widely used for producing long rods, tubes, and complex cross-sections with high dimensional accuracy. Your choice depends on factors like material type, product shape, and production efficiency.

What is Indirect Extrusion?

Indirect extrusion is a metal forming process where the billet remains stationary while the die moves through it, reducing friction between the billet and the container. This method enhances material flow, resulting in less wear on the equipment and improved surface finish of the extruded product. Indirect extrusion is commonly used for materials with low ductility and requires less extrusion force compared to direct extrusion.

Key Process Differences

Direct extrusion forces the billet to move through the container and out the die by pushing it forward, creating high friction between the billet and container walls. Indirect extrusion involves the die moving toward the stationary billet, reducing friction as the billet remains static within the container. Your choice between these methods depends on factors such as material type, required surface finish, and pressure limitations.

Equipment and Tooling Requirements

Direct extrusion requires a robust container and a rigid ram to withstand high friction forces as the billet moves against the container walls, while indirect extrusion uses a hollow ram or punch where the billet remains stationary and the die moves towards it, reducing friction. Equipment for direct extrusion typically involves heavier, more rigid presses and tooling to handle significant force and wear on the container and billet surface. Indirect extrusion benefits from lower tooling wear and energy consumption due to reduced friction, enabling simpler die design and longer tool life in equipment setups.

Advantages of Direct Extrusion

Direct extrusion offers advantages such as the ability to produce complex cross-sectional shapes with high dimensional accuracy and surface finish. It allows for higher production rates due to simpler tooling and faster setup times, reducing overall manufacturing costs. Your choice of direct extrusion can also accommodate a wider range of metals and alloy materials, making it versatile for various industrial applications.

Advantages of Indirect Extrusion

Indirect extrusion offers significant advantages such as reduced friction between the billet and the container, leading to lower required extrusion force and extended tool life. This process minimizes billet heating and material waste, enhancing energy efficiency and cost-effectiveness. Moreover, indirect extrusion provides improved surface finish and dimensional accuracy for complex cross-sectional profiles.

Limitations of Each Method

Direct extrusion faces limitations such as high friction between the billet and container, leading to increased force requirements and potential surface defects. Indirect extrusion reduces friction by keeping the billet stationary, but it is constrained by lower billet sizes and more complex tooling that can increase manufacturing costs. Your choice between these methods depends on balancing material properties, product shape, and production efficiency.

Typical Applications and Industries

Direct extrusion commonly serves industries such as automotive, aerospace, and construction for manufacturing solid and hollow profiles, rods, and tubes due to its versatility in shaping aluminum, copper, and steel alloys. Indirect extrusion finds typical applications in producing seamless tubes, precision rods, and complex cross-sections, especially in sectors like electronics, medical devices, and high-performance engineering where reduced friction and improved material flow are critical. Both methods are essential in metal forming, with direct extrusion favored for larger production runs and indirect extrusion preferred for high-quality surface finishes and reduced tooling wear.

Choosing the Right Extrusion Technique

Direct extrusion offers greater versatility for producing complex cross-sections and is ideal for high-strength materials due to its ability to withstand higher extrusion pressures. Indirect extrusion reduces friction between the billet and container walls, resulting in lower required force and better surface finish, making it suitable for softer materials and long, continuous profiles. Selecting the right extrusion technique depends on factors such as material properties, desired product shape, and production efficiency requirements.

Direct extrusion vs indirect extrusion Infographic

libmatt.com

libmatt.com