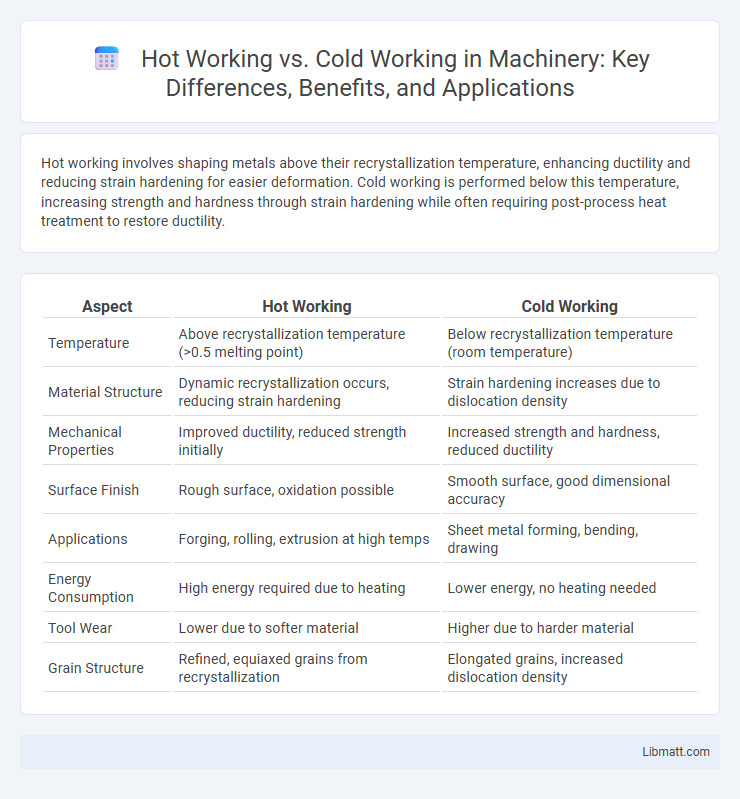

Hot working involves shaping metals above their recrystallization temperature, enhancing ductility and reducing strain hardening for easier deformation. Cold working is performed below this temperature, increasing strength and hardness through strain hardening while often requiring post-process heat treatment to restore ductility.

Table of Comparison

| Aspect | Hot Working | Cold Working |

|---|---|---|

| Temperature | Above recrystallization temperature (>0.5 melting point) | Below recrystallization temperature (room temperature) |

| Material Structure | Dynamic recrystallization occurs, reducing strain hardening | Strain hardening increases due to dislocation density |

| Mechanical Properties | Improved ductility, reduced strength initially | Increased strength and hardness, reduced ductility |

| Surface Finish | Rough surface, oxidation possible | Smooth surface, good dimensional accuracy |

| Applications | Forging, rolling, extrusion at high temps | Sheet metal forming, bending, drawing |

| Energy Consumption | High energy required due to heating | Lower energy, no heating needed |

| Tool Wear | Lower due to softer material | Higher due to harder material |

| Grain Structure | Refined, equiaxed grains from recrystallization | Elongated grains, increased dislocation density |

Introduction to Metal Working Processes

Hot working involves deforming metals above their recrystallization temperature, enhancing ductility and reducing strain hardening for easier shaping. Cold working takes place below the recrystallization temperature, increasing the metal's strength and hardness through strain hardening while maintaining tight dimensional tolerances. Your choice between hot and cold working depends on the desired mechanical properties and final application of the metal component.

Defining Hot Working

Hot working involves shaping metals at temperatures above their recrystallization point, allowing for significant deformation without cracking. This process enhances ductility and reduces residual stresses, making it ideal for forming complex shapes and large workpieces. Your manufacturing efficiency improves as hot working refines the metal's grain structure, providing better mechanical properties.

Defining Cold Working

Cold working refers to the process of deforming metals below their recrystallization temperature, typically at room temperature, to enhance strength through strain hardening. This method preserves the metal's original grain structure while improving surface finish and dimensional accuracy. Understanding cold working helps you select the appropriate technique for applications requiring increased hardness and precise tolerances.

Comparison of Process Temperatures

Hot working occurs above the material's recrystallization temperature, typically above 700degC for steel, enabling easier deformation and grain refinement. Cold working takes place below this temperature, often room temperature, resulting in strain hardening and increased strength but reduced ductility. Your choice between hot and cold working significantly influences the mechanical properties and surface finish of the final product.

Material Properties: Hot vs Cold Working

Hot working processes involve deforming metals above their recrystallization temperature, resulting in improved ductility and reduced strength due to dynamic recovery and recrystallization. Cold working occurs below the recrystallization temperature, increasing strength and hardness through strain hardening but reducing ductility and making the material more brittle. Understanding these material properties helps you select the appropriate process for desired mechanical characteristics and manufacturing goals.

Surface Finish and Dimensional Accuracy

Cold working produces superior surface finish and higher dimensional accuracy due to minimal thermal distortion and work hardening effects. Hot working, performed above the material's recrystallization temperature, results in rougher surfaces and less precise dimensions caused by oxidation and thermal expansion. Understanding these differences helps you select the optimal process for tight tolerances and smooth finishes in metal fabrication.

Advantages of Hot Working

Hot working improves material ductility and reduces the risk of work hardening by processing metals above their recrystallization temperature. This method refines grain structure and enhances mechanical properties, leading to improved strength and toughness in the finished product. You benefit from better formability and reduced deformation resistance, making hot working ideal for shaping complex components.

Advantages of Cold Working

Cold working enhances material strength and hardness through strain hardening, improving wear resistance and durability. It maintains tight dimensional tolerances and superior surface finish without the need for additional machining. Your manufacturing process benefits from increased mechanical properties while minimizing thermal distortion and oxidation risks.

Typical Applications and Industries

Hot working is commonly used in industries such as automotive manufacturing, aerospace, and heavy machinery production, where shaping metals like steel and aluminum at high temperatures enhances ductility and reduces risk of fractures. Cold working finds typical applications in the production of sheet metal parts, springs, and fasteners within electronics, appliance manufacturing, and construction sectors, offering improved surface finish and higher strength through strain hardening. Both processes play critical roles in forging, rolling, and extrusion techniques tailored to meet specific mechanical and structural requirements across diverse industrial landscapes.

Selecting the Right Process: Key Considerations

Selecting the right process between hot working and cold working depends on factors such as material type, desired mechanical properties, and production volume. Hot working is ideal for shaping metals like steel or aluminum at high temperatures to improve ductility and reduce residual stresses, while cold working enhances strength and surface finish through strain hardening at room temperature. Your choice should balance cost efficiency, final product specifications, and the potential need for subsequent heat treatments.

Hot working vs cold working Infographic

libmatt.com

libmatt.com