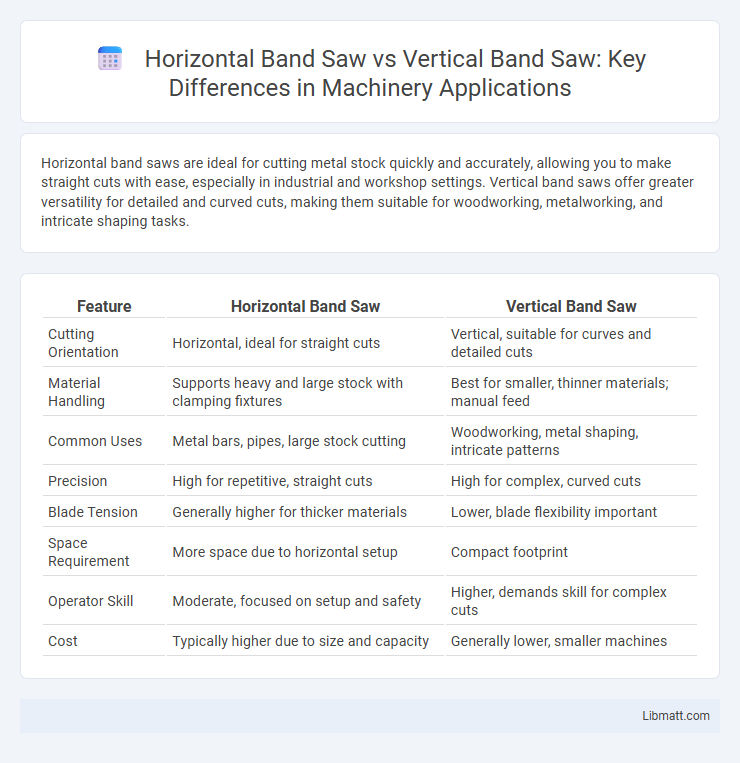

Horizontal band saws are ideal for cutting metal stock quickly and accurately, allowing you to make straight cuts with ease, especially in industrial and workshop settings. Vertical band saws offer greater versatility for detailed and curved cuts, making them suitable for woodworking, metalworking, and intricate shaping tasks.

Table of Comparison

| Feature | Horizontal Band Saw | Vertical Band Saw |

|---|---|---|

| Cutting Orientation | Horizontal, ideal for straight cuts | Vertical, suitable for curves and detailed cuts |

| Material Handling | Supports heavy and large stock with clamping fixtures | Best for smaller, thinner materials; manual feed |

| Common Uses | Metal bars, pipes, large stock cutting | Woodworking, metal shaping, intricate patterns |

| Precision | High for repetitive, straight cuts | High for complex, curved cuts |

| Blade Tension | Generally higher for thicker materials | Lower, blade flexibility important |

| Space Requirement | More space due to horizontal setup | Compact footprint |

| Operator Skill | Moderate, focused on setup and safety | Higher, demands skill for complex cuts |

| Cost | Typically higher due to size and capacity | Generally lower, smaller machines |

Introduction to Band Saws

Band saws, essential for precise cutting of various materials, come primarily in two types: horizontal and vertical. Horizontal band saws excel in straight, repetitive cuts, ideal for metalworking and industrial applications. Vertical band saws offer versatility for curved and intricate cuts, making them suitable for woodworking and detailed fabrication tasks that enhance your project's precision.

Horizontal Band Saw: Overview and Features

Horizontal band saws feature a blade mounted on a horizontal arm, designed for cutting larger, heavy-duty materials with precision and efficiency. Their robust frames and powerful motors provide stable, straight cuts in metal, wood, or plastic, making them ideal for industrial and manufacturing settings. If your projects demand high volume and consistently accurate crosscuts, a horizontal band saw enhances productivity and reduces material waste.

Vertical Band Saw: Overview and Features

Vertical band saws feature a vertically oriented blade that offers precise, intricate cuts ideal for detailed woodworking and metalworking projects. These saws provide greater control for curved, irregular, and resawing cuts, often equipped with adjustable blade guides and tilting tables to enhance versatility. Advanced models include powerful motors and variable speed settings to optimize performance across different materials and thicknesses, making them essential tools for professionals requiring accuracy and flexibility.

Key Differences Between Horizontal and Vertical Band Saws

Horizontal band saws feature a blade that moves horizontally, ideal for cutting large, heavy materials like metal pipes and bars with higher precision and efficiency. Vertical band saws have a blade that moves vertically, providing greater versatility for intricate shapes, curves, and detailed woodworking or metalworking tasks. Choosing between these tools depends on your specific cutting needs, with horizontal saws suited for straight cuts on bulky workpieces and vertical saws for more detailed, complex cuts.

Cutting Techniques and Applications

Horizontal band saws excel in making straight cuts through thick metal stock, often used in fabrication shops for cutting bars, pipes, and structural materials. Vertical band saws offer greater versatility with the ability to execute irregular, curved, and intricate cuts, making them ideal for woodworking, metal shaping, and detailed fabrication tasks. Choosing between horizontal and vertical band saws depends on the specific cutting technique required and the material shape and thickness being processed.

Material Compatibility and Versatility

Horizontal band saws excel in cutting dense materials like metals and thick steel due to their powerful downward force, while vertical band saws offer greater versatility for intricate cuts on a wider range of materials such as wood, plastics, and softer metals. Your choice should consider the machine's blade guides and motor strength, which impact compatibility with specific materials and the precision of cuts. Vertical band saws provide better control for contour and curve cutting, making them ideal for detailed work, whereas horizontal band saws are more efficient for straight, repetitive cuts on heavy-duty materials.

Precision and Accuracy Comparison

Horizontal band saws typically offer greater precision and accuracy for cutting metal due to their stable frame and controlled feed rate, ensuring consistent straight cuts. Vertical band saws provide versatility in cutting irregular shapes and curves but may sacrifice some accuracy on straight, precise cuts compared to horizontal models. For your projects requiring high precision and accuracy in straight cuts, a horizontal band saw is generally the better choice.

Space and Maintenance Considerations

Horizontal band saws typically require more floor space due to their larger cutting area and material handling setup, making them suitable for workshops with ample room. Vertical band saws offer a compact footprint, ideal for smaller spaces or operations emphasizing precision over volume. Your maintenance routine will vary; horizontal saws often need more frequent blade tension adjustments and coolant system checks, while vertical saws generally demand attention to blade tracking and guide alignment to ensure optimal performance.

Cost and Budget Implications

Horizontal band saws generally have higher upfront costs compared to vertical band saws due to their larger size and enhanced cutting capacity. Vertical band saws tend to be more budget-friendly, making them suitable for smaller workshops or hobbyists with limited funds. Your choice should balance initial investment with project needs, as horizontal models may offer long-term value through efficiency despite higher initial expenses.

Choosing the Right Band Saw for Your Needs

Selecting between a horizontal band saw and a vertical band saw depends on the type of material and cutting precision required. Horizontal band saws excel in cutting larger, thicker materials with straight, repetitive cuts, ideal for metal fabrication and large stock processing. Vertical band saws offer greater versatility for intricate, curved, or irregular cuts, making them suitable for woodworking, detailed metalwork, and customized shapes.

Horizontal band saw vs vertical band saw Infographic

libmatt.com

libmatt.com