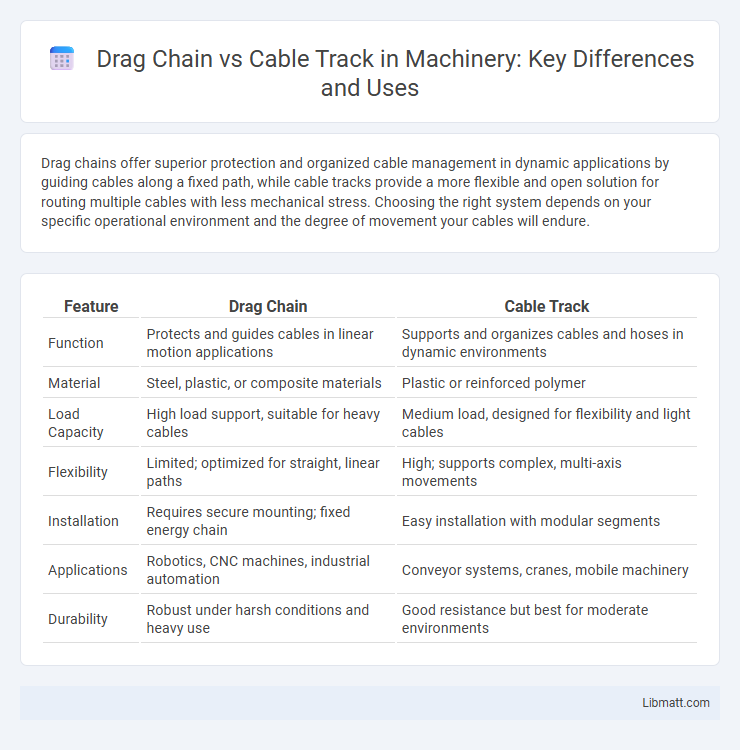

Drag chains offer superior protection and organized cable management in dynamic applications by guiding cables along a fixed path, while cable tracks provide a more flexible and open solution for routing multiple cables with less mechanical stress. Choosing the right system depends on your specific operational environment and the degree of movement your cables will endure.

Table of Comparison

| Feature | Drag Chain | Cable Track |

|---|---|---|

| Function | Protects and guides cables in linear motion applications | Supports and organizes cables and hoses in dynamic environments |

| Material | Steel, plastic, or composite materials | Plastic or reinforced polymer |

| Load Capacity | High load support, suitable for heavy cables | Medium load, designed for flexibility and light cables |

| Flexibility | Limited; optimized for straight, linear paths | High; supports complex, multi-axis movements |

| Installation | Requires secure mounting; fixed energy chain | Easy installation with modular segments |

| Applications | Robotics, CNC machines, industrial automation | Conveyor systems, cranes, mobile machinery |

| Durability | Robust under harsh conditions and heavy use | Good resistance but best for moderate environments |

Introduction to Drag Chains and Cable Tracks

Drag chains and cable tracks are essential components in managing and protecting cables in automated machinery and robotics. Drag chains, also known as energy chains, consist of interconnected links that guide flexible cables and hoses to prevent tangling and mechanical stress. Cable tracks share a similar purpose but often feature a continuous, enclosed structure for enhanced protection against environmental factors and debris.

What is a Drag Chain?

A drag chain, also known as an energy chain, is a protective system designed to guide and shield cables and hoses in dynamic applications, preventing tangling, wear, and damage during movement. Commonly made from durable plastic or metal, drag chains maintain cable organization and ensure smooth operation in machinery with repetitive motion, such as CNC machines and robotic arms. Their modular design allows for easy length adjustments and customization based on machine requirements, making them essential for reliable cable management in automated environments.

What is a Cable Track?

A cable track is a protective system designed to guide and support cables, wires, and hoses in dynamic applications, ensuring smooth movement and preventing damage from bending or abrasion. Unlike drag chains that often feature interlocking links and rigid segments, cable tracks typically incorporate flexible, yet durable materials that allow for continuous motion in confined spaces. These tracks optimize cable management in robotics, automation, and industrial machinery by maintaining organization and improving operational reliability.

Key Differences Between Drag Chains and Cable Tracks

Drag chains are rigid structures designed to support and protect cables during linear motion, providing controlled bending and preventing cable entanglement, while cable tracks are flexible guides that allow cables to move in multiple directions with less structural rigidity. Unlike cable tracks, drag chains maintain a fixed bend radius to reduce cable fatigue and extend the life of the cables within dynamic applications. Understanding these key differences helps you select the ideal cable management system based on your machinery's movement requirements and durability needs.

Advantages of Drag Chains

Drag chains provide superior protection against abrasion and external damage for cables, ensuring longer lifespan and reliable performance in dynamic applications. Their modular design allows easy customization and maintenance, making them ideal for complex machinery with frequent movement. You benefit from enhanced cable organization and reduced downtime, optimizing overall system efficiency.

Advantages of Cable Tracks

Cable tracks offer superior protection for cables and hoses, preventing tangling, abrasion, and external damage during dynamic movements. Their modular design allows easy customization and maintenance, enhancing the durability and lifespan of your machinery components. Using cable tracks improves operational efficiency by ensuring smooth, organized cable routing in complex industrial environments.

Applications: When to Use Drag Chains vs Cable Tracks

Drag chains excel in applications requiring precise cable protection and organization in dynamic machinery with limited space, such as CNC machines and robotic arms. Cable tracks are ideal for heavy-duty industrial environments where cables need robust support and smoother movement over longer distances, like conveyor systems and automated warehouses. Choosing the right option depends on Your equipment's movement complexity, weight capacity, and spatial constraints.

Factors to Consider When Choosing Between Drag Chains and Cable Tracks

Choosing between drag chains and cable tracks depends on factors such as load capacity, flexibility, and environmental conditions. Drag chains offer superior protection and organization for heavy cables in dynamic applications, while cable tracks provide easier installation and maintenance for lighter, more flexible cables. Consider operational speed, bend radius, and space constraints to optimize cable management efficiency and longevity.

Maintenance and Durability Comparison

Drag chains typically require less maintenance due to their rigid structure, which protects cables from wear and external damage, enhancing overall durability in harsh environments. Cable tracks offer more flexibility but may demand frequent inspections to prevent cable tangling or abrasion, impacting their lifespan. Your choice should consider the operational conditions, as drag chains excel in high-stress settings while cable tracks perform well in applications requiring dynamic movement.

Conclusion: Which is Right for Your Application?

Drag chains provide superior protection and organization for cables in dynamic industrial environments with frequent movement, offering durability and easy maintenance. Cable tracks are ideal for lighter applications where flexibility and cost-effectiveness are priorities, especially in less demanding or static setups. Selecting the right option depends on your specific load requirements, environmental conditions, and movement frequency to optimize cable lifespan and system reliability.

Drag chain vs cable track Infographic

libmatt.com

libmatt.com